Industrial printing operations depend heavily on precision cutting equipment to maintain quality standards and operational efficiency. A well-maintained paper cutter machine represents the cornerstone of any successful commercial printing facility, where even minor deviations in cutting accuracy can result in significant material waste and production delays. Understanding the critical relationship between regular maintenance practices and machine performance helps facilities maximize their equipment investment while ensuring consistent output quality. Professional operators recognize that preventive maintenance protocols extend far beyond simple blade sharpening, encompassing comprehensive calibration procedures that maintain cutting precision across thousands of operational cycles.

Understanding Paper Cutter Machine Components and Their Maintenance Requirements

Essential Blade Components and Wear Patterns

The cutting blade serves as the primary component determining output quality in any paper cutter machine system. Modern industrial blades feature hardened steel construction with specialized coatings designed to maintain sharp edges through extended use periods. Regular inspection reveals common wear patterns including edge dulling, micro-chipping, and uneven wear distribution across the blade length. These degradation patterns directly impact cutting precision and can introduce variations in cut quality that compromise finished product specifications.

Professional maintenance teams monitor blade condition through systematic inspection protocols that identify early warning signs of deterioration. Edge geometry changes become apparent through microscopic examination, revealing the gradual transition from sharp cutting edges to rounded profiles that increase cutting resistance. Understanding these wear characteristics enables proactive replacement scheduling that prevents quality degradation before it affects production output.

Calibration Systems and Precision Mechanisms

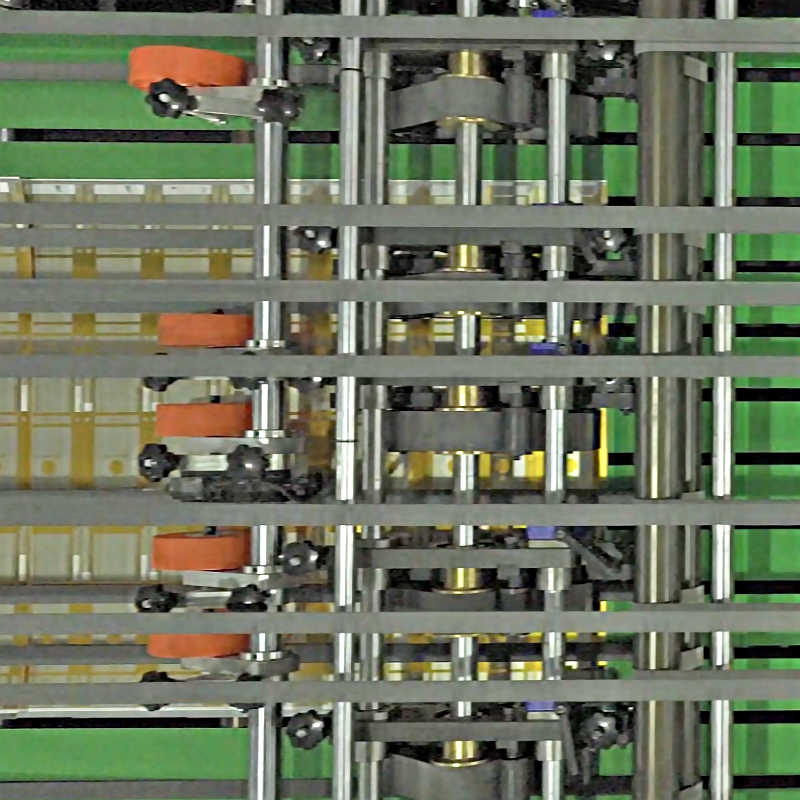

Advanced paper cutter machine designs incorporate sophisticated calibration systems that maintain cutting accuracy across varying material thicknesses and densities. These mechanisms include adjustable back gauges, pressure plate systems, and hydraulic clamping components that require periodic calibration to maintain specified tolerances. Calibration drift occurs naturally through normal operation as mechanical components experience wear and thermal expansion cycles.

Digital measurement systems integrated into modern equipment provide real-time feedback on cutting accuracy, enabling operators to detect calibration drift before it affects product quality. Regular calibration procedures restore original factory specifications, ensuring consistent performance across all operational parameters. These systems require specialized knowledge and precision measurement tools to achieve optimal adjustment results.

Impact of Maintenance Neglect on Operational Performance

Production Efficiency Degradation

Inadequate maintenance practices create cascading effects throughout paper cutter machine operations, beginning with reduced cutting speed and progressing to complete operational failures. Dull blades require increased cutting pressure to achieve clean cuts, placing additional stress on drive systems and hydraulic components. This increased mechanical stress accelerates wear rates across multiple system components, creating compounding maintenance requirements that exceed normal service intervals.

Production throughput suffers as operators compensate for declining performance by reducing cutting speeds or implementing multiple pass cutting procedures. These operational modifications significantly impact daily production capacity while increasing labor costs associated with extended setup times and manual quality inspection procedures. Facilities experiencing maintenance neglect report productivity losses ranging from fifteen to forty percent compared to properly maintained equipment.

Quality Control Challenges and Material Waste

Precision cutting operations demand consistent dimensional accuracy to meet customer specifications and minimize material waste. A poorly maintained paper cutter machine produces irregular cut edges, dimensional variations, and surface quality defects that render finished products unsuitable for delivery. Quality control systems detect these variations, requiring expensive rework procedures or complete material replacement to meet contractual obligations.

Material waste calculations demonstrate the economic impact of maintenance neglect, with some facilities reporting waste rates exceeding ten percent of total material consumption. Premium substrates used in high-value applications magnify these costs, making preventive maintenance programs essential for maintaining competitive profit margins. Advanced monitoring systems track waste generation patterns, providing quantitative data that supports maintenance investment decisions.

Comprehensive Maintenance Protocols for Optimal Performance

Daily Inspection and Cleaning Procedures

Effective maintenance begins with structured daily inspection routines that identify potential issues before they impact production operations. Operators trained in proper inspection techniques examine blade edges for visible wear, check cutting guides for alignment accuracy, and verify hydraulic system operation through systematic pressure checks. These daily procedures require minimal time investment while providing early detection of developing maintenance requirements.

Cleaning protocols remove paper dust, adhesive residues, and other contaminants that accumulate during normal operation of any paper cutter machine. These materials can interfere with precision mechanisms and accelerate wear rates if allowed to accumulate. Professional cleaning procedures utilize appropriate solvents and cleaning tools that effectively remove contaminants without damaging sensitive components or precision surfaces.

Scheduled Calibration and Adjustment Procedures

Systematic calibration schedules ensure consistent cutting accuracy throughout equipment service life, typically implementing monthly precision checks using certified reference standards. These procedures verify dimensional accuracy across the full cutting width, check parallelism between cutting blade and back gauge systems, and confirm proper operation of all safety interlocks. Calibration records provide historical data that supports predictive maintenance decisions and warranty compliance requirements.

Professional calibration procedures require specialized measurement equipment including precision rulers, dial indicators, and electronic measurement systems capable of detecting variations measured in thousandths of an inch. Proper calibration technique follows manufacturer specifications while accounting for environmental factors such as temperature variations that can affect measurement accuracy. Documentation of all calibration activities creates audit trails supporting quality management system requirements.

Advanced Maintenance Technologies and Monitoring Systems

Predictive Maintenance Integration

Modern paper cutter machine designs incorporate sophisticated monitoring systems that enable predictive maintenance approaches based on actual equipment condition rather than arbitrary time intervals. Vibration analysis systems detect mechanical wear patterns, temperature monitoring identifies thermal stress conditions, and cutting force measurement reveals blade condition changes. These technologies provide quantitative data supporting optimal maintenance timing decisions.

Integration of Internet of Things technology enables remote monitoring capabilities that alert maintenance personnel to developing issues before they impact production operations. Cloud-based data analysis systems compare current performance metrics against historical patterns, identifying trends that indicate approaching maintenance requirements. These advanced systems reduce maintenance costs while improving equipment reliability through optimized service scheduling.

Automated Calibration and Adjustment Systems

Advanced automation technologies eliminate manual calibration procedures through integrated measurement and adjustment systems that maintain cutting accuracy automatically. These systems continuously monitor cutting performance and implement micro-adjustments that compensate for normal wear patterns. Automated systems reduce operator skill requirements while ensuring consistent calibration accuracy across all operational conditions.

Self-calibrating paper cutter machine designs incorporate feedback control systems that maintain specified tolerances through continuous adjustment cycles. These sophisticated systems represent the current state of cutting technology, offering unprecedented accuracy and consistency while reducing manual maintenance requirements. Investment in advanced automation technology pays dividends through improved product quality and reduced operational costs.

Economic Benefits of Proper Maintenance Investment

Cost Analysis and Return on Investment

Comprehensive maintenance programs require significant upfront investment in training, tools, and spare parts inventory, but generate substantial returns through improved operational efficiency and reduced downtime costs. Economic analysis demonstrates that properly maintained paper cutter machine equipment experiences fifty percent fewer unexpected failures compared to equipment receiving minimal maintenance attention. These reliability improvements translate directly to increased production capacity and reduced emergency repair costs.

Maintenance cost tracking reveals that preventive maintenance expenses typically represent less than twenty percent of total equipment ownership costs when properly implemented. Emergency repair costs and production interruption losses associated with equipment failures far exceed preventive maintenance investments, making structured maintenance programs essential for profitable operations. Financial modeling supports maintenance investment decisions through quantitative analysis of cost-benefit relationships.

Extended Equipment Service Life

Regular maintenance practices significantly extend paper cutter machine service life, with properly maintained equipment operating reliably for twenty years or more compared to ten-year average service life for neglected equipment. Extended service life reduces capital equipment replacement costs while maintaining competitive production capabilities throughout the equipment lifecycle. Maintenance investment pays dividends through deferred capital expenditures and improved return on equipment investment.

Component replacement scheduling based on condition monitoring extends service intervals while preventing unexpected failures that can damage multiple system components simultaneously. Strategic maintenance timing minimizes production disruption while optimizing component service life through proper operating conditions. Professional maintenance programs balance immediate costs against long-term equipment preservation objectives.

FAQ

How often should paper cutter machine blades be replaced

Blade replacement frequency depends on usage intensity, material types, and cutting volume, but typically ranges from every 50,000 to 200,000 cuts for industrial applications. Regular inspection of blade condition provides better replacement timing indicators than arbitrary schedules, as wear rates vary significantly based on operational conditions. Professional operators monitor cutting quality and force requirements to determine optimal replacement timing that prevents quality degradation while maximizing blade service life.

What are the signs that indicate calibration is needed

Key indicators requiring calibration attention include dimensional variations exceeding specified tolerances, uneven cutting pressure across the blade width, and visible gaps or misalignment between cutting components. Production quality issues such as rough cut edges, dimensional inconsistency, or increased material waste often signal calibration drift that requires professional adjustment. Regular measurement verification using precision standards detects calibration issues before they affect production output quality.

Can maintenance procedures be performed by regular operators

Basic maintenance procedures including daily cleaning, visual inspection, and simple adjustments can be performed by trained operators following established protocols. Complex calibration procedures, blade replacement, and hydraulic system maintenance require specialized training and precision tools typically handled by qualified maintenance technicians. Proper training programs ensure operators understand their maintenance responsibilities while recognizing situations requiring professional technical support.

What is the cost difference between preventive and reactive maintenance approaches

Preventive maintenance programs typically cost sixty to seventy percent less than reactive maintenance approaches when total ownership costs including downtime, emergency repairs, and production losses are considered. Emergency repairs often require expedited parts delivery and overtime labor costs that significantly exceed scheduled maintenance expenses. Comprehensive cost analysis demonstrates that preventive maintenance investment provides substantial economic benefits through improved equipment reliability and reduced operational disruption.

Table of Contents

- Understanding Paper Cutter Machine Components and Their Maintenance Requirements

- Impact of Maintenance Neglect on Operational Performance

- Comprehensive Maintenance Protocols for Optimal Performance

- Advanced Maintenance Technologies and Monitoring Systems

- Economic Benefits of Proper Maintenance Investment

- FAQ