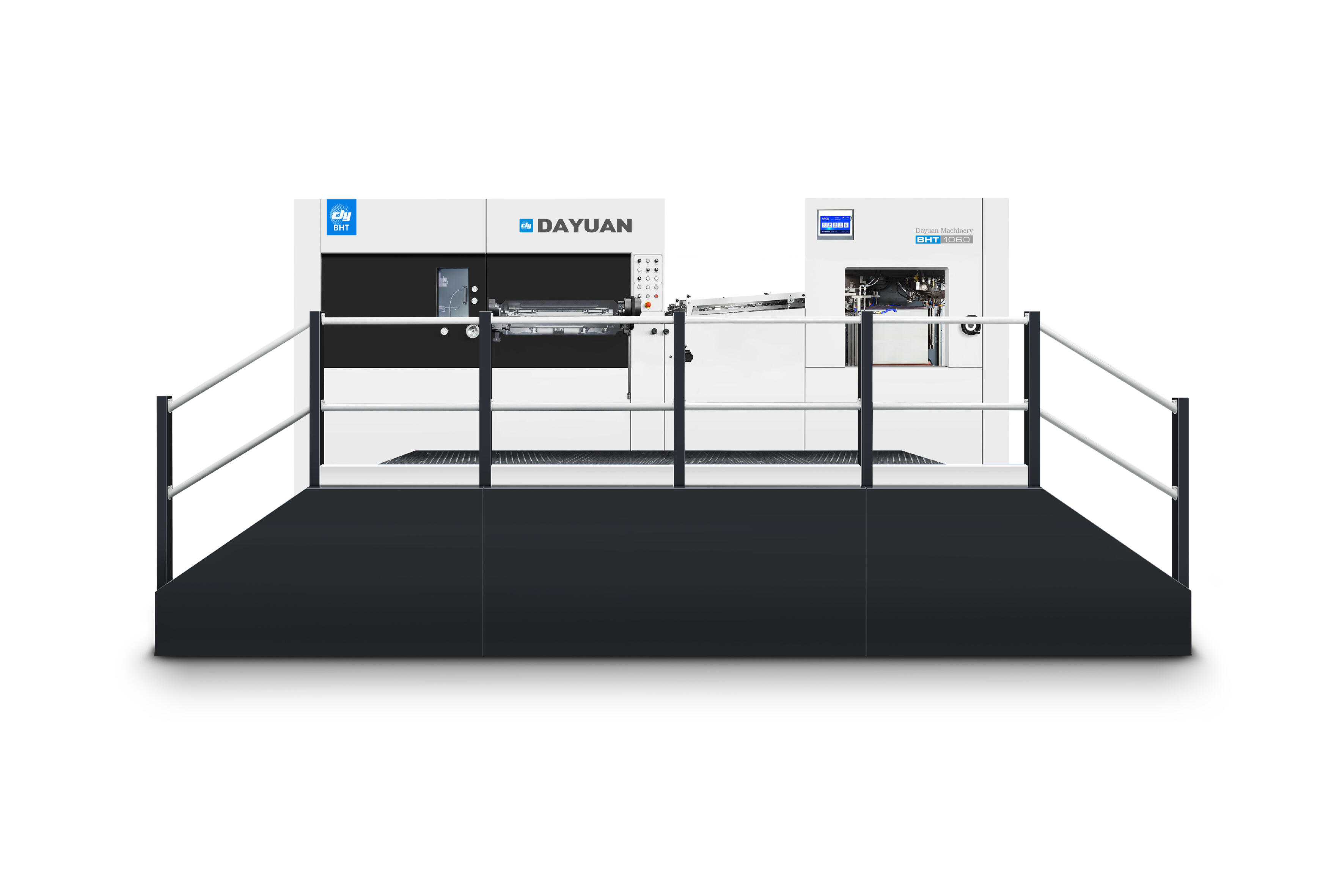

Industrial packaging and printing operations rely heavily on the consistent performance of their paper die cutting machine systems to meet demanding production schedules. These sophisticated pieces of equipment process thousands of sheets per hour, creating precise cuts and creases that form the foundation of countless consumer products. Understanding the critical maintenance requirements for high-cycle operations ensures optimal productivity, reduces unexpected downtime, and extends the operational lifespan of these valuable manufacturing assets. Professional maintenance protocols become increasingly important as production volumes increase and quality tolerances tighten in competitive markets.

Essential Daily Maintenance Procedures

Pre-Operation Inspection Protocol

Beginning each production shift with a comprehensive inspection routine establishes the foundation for reliable paper die cutting machine performance throughout the day. Operators should examine all safety guards, emergency stops, and protective barriers to ensure proper positioning and functionality. Visual inspection of the feeding mechanism reveals potential issues with paper alignment guides, suction systems, and conveyor belts that could affect material handling precision. These preliminary checks identify minor problems before they escalate into costly production interruptions or safety hazards.

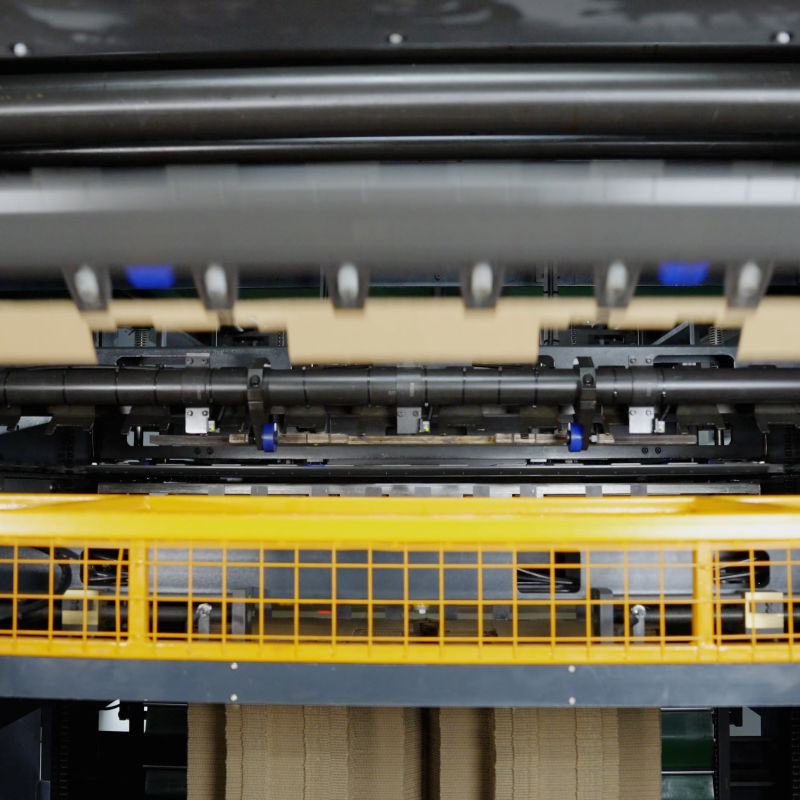

The cutting platform requires careful examination for debris, adhesive residue, or worn cutting strips that might compromise cutting accuracy. Operators must verify that die boards are properly secured and aligned within their mounting systems. Any loose fasteners, damaged cutting edges, or misaligned components should be addressed immediately to maintain consistent output quality. Documentation of these daily inspections creates valuable maintenance records that help identify recurring issues and optimize preventive maintenance schedules.

Lubrication System Management

Proper lubrication forms the cornerstone of mechanical reliability in high-speed paper die cutting machine operations. Daily lubrication points include all bearing assemblies, cam followers, and sliding mechanisms that experience continuous motion during production cycles. Using manufacturer-specified lubricants ensures compatibility with sealing materials and prevents chemical degradation of critical components. Operators should maintain consistent lubrication schedules and monitor consumption rates to identify potential seal failures or excessive wear conditions.

Automated lubrication systems require daily verification of reservoir levels, pump operation, and distribution line integrity. Manual lubrication points need attention using proper techniques that avoid over-lubrication, which can attract debris and interfere with precision mechanisms. Temperature monitoring of lubricated components helps identify developing problems such as bearing deterioration or alignment issues that increase friction and heat generation. Regular lubrication system maintenance prevents premature component failure and maintains the smooth operation essential for high-volume production environments.

Weekly Calibration and Adjustment Procedures

Cutting Pressure Optimization

Weekly calibration of cutting pressure settings ensures optimal performance across varying substrate types and thickness variations commonly encountered in diverse production runs. The paper die cutting machine requires precise pressure adjustments to achieve clean cuts without excessive force that could damage dies or create premature wear patterns. Systematic pressure testing using standardized substrate samples provides consistent reference points for optimal settings across different material specifications and production requirements.

Pressure distribution across the entire cutting platform must remain uniform to prevent uneven wear patterns and maintain consistent cutting quality. Weekly verification involves testing multiple points across the cutting surface using pressure-sensitive films or electronic measurement devices. Any variations exceeding manufacturer tolerances require immediate adjustment of leveling mechanisms, replacement of worn cutting strips, or correction of platform distortion. These calibration procedures ensure uniform product quality and prevent costly die damage from excessive or uneven pressure application.

Registration and Timing Adjustments

Accurate registration between paper feeding mechanisms and cutting cycles maintains precise positioning essential for complex die cutting operations. Weekly verification of timing sequences ensures proper coordination between material advancement, die engagement, and waste removal systems. Electronic sensors and mechanical timing devices require calibration to maintain synchronization within specified tolerances. Any drift in timing parameters can result in misaligned cuts, material waste, and reduced production efficiency.

Registration systems include photocell sensors, mechanical stops, and electronic positioning controls that require periodic adjustment and cleaning. Dust accumulation on optical sensors can cause erratic operation and positioning errors. Weekly cleaning and calibration of these systems using manufacturer-approved procedures maintains consistent positioning accuracy. Documentation of timing adjustments helps identify trends that might indicate developing mechanical problems or the need for component replacement.

Monthly Deep Maintenance and Component Inspection

Die Board and Cutting Rule Maintenance

Monthly inspection of die boards reveals wear patterns, damaged cutting rules, and creasing blade condition that affects product quality and production efficiency. Die boards experience significant stress during high-cycle operations, and systematic evaluation prevents unexpected failures during production runs. Cutting rules require examination for nicks, dullness, or height variations that compromise cutting performance. Professional resharpening or replacement maintains optimal cutting quality and prevents damage to paper die cutting machine components.

Creasing rules and scoring blades need regular inspection for proper height adjustment and edge condition. Worn or damaged creasing elements create poor fold quality and may require excessive pressure that accelerates machine wear. Monthly die board maintenance includes cleaning, rule adjustment, and replacement of worn components according to manufacturer specifications. Proper die maintenance extends tool life, maintains product quality, and reduces the mechanical stress placed on machine components during operation.

Electrical System and Control Panel Maintenance

Comprehensive electrical system maintenance prevents unexpected control failures and maintains precise operation of sophisticated paper die cutting machine control systems. Monthly inspection includes verification of all electrical connections, examination of wire insulation, and testing of safety interlocks and emergency stop functions. Control panels require cleaning of contacts, verification of display accuracy, and testing of input/output functions. Any signs of electrical degradation, such as discolored connections or erratic operation, require immediate professional attention.

Servo motors and drive systems need monthly inspection of mounting hardware, electrical connections, and encoder feedback systems. Proper electrical maintenance prevents costly component failures and ensures reliable operation of automated functions. Temperature monitoring of electrical cabinets and motor drives identifies potential cooling system problems or electrical loading issues. Regular electrical system maintenance maintains the precision and reliability essential for modern automated paper die cutting machine operations.

Seasonal and Annual Maintenance Programs

Comprehensive Mechanical Overhaul

Annual mechanical overhaul procedures address wear patterns and component degradation that develop over extended high-cycle operation periods. This comprehensive maintenance involves complete disassembly of major mechanical systems, measurement of critical dimensions, and replacement of worn components according to manufacturer specifications. Bearing assemblies, drive components, and precision mechanisms require professional evaluation and servicing to maintain optimal performance standards.

Structural alignment verification ensures that the paper die cutting machine foundation and mounting systems maintain proper geometry under operational loads. Frame distortion or foundation settling can create alignment problems that affect cutting accuracy and accelerate component wear. Professional measurement and adjustment of structural elements prevents progressive deterioration and maintains the precision essential for quality production. Complete mechanical overhaul extends machine life and ensures reliable performance for continued high-volume operations.

Environmental System Maintenance

Seasonal maintenance of environmental control systems maintains optimal operating conditions for sensitive paper die cutting machine components. Dust collection systems require thorough cleaning and filter replacement to maintain proper airflow and prevent contamination of precision mechanisms. Air conditioning and heating systems need professional servicing to maintain temperature and humidity control essential for consistent material handling and dimensional stability.

Compressed air systems require annual inspection of compressors, air treatment equipment, and distribution piping. Moisture and contamination in compressed air systems can damage pneumatic components and affect operation reliability. Professional servicing includes replacement of filters, drain valves, and pressure regulation equipment. Proper environmental system maintenance creates stable operating conditions that enhance paper die cutting machine performance and extend component life.

Preventive Maintenance Documentation and Record Keeping

Maintenance Schedule Development

Systematic documentation of all maintenance activities creates valuable data for optimizing preventive maintenance schedules and identifying recurring issues before they cause production problems. Comprehensive maintenance records include component replacement dates, service intervals, and performance measurements that help predict future maintenance needs. Digital maintenance management systems facilitate scheduling, tracking, and analysis of maintenance activities across multiple paper die cutting machine installations.

Maintenance scheduling software integrates with production planning systems to minimize disruption while ensuring adequate maintenance coverage. Predictive maintenance algorithms analyze historical data to optimize service intervals and identify components approaching end-of-life conditions. Proper documentation and scheduling prevent unexpected failures while maximizing productive operating time between maintenance intervals.

Performance Monitoring and Analysis

Continuous performance monitoring provides early warning of developing problems and validates the effectiveness of maintenance procedures. Key performance indicators include production rates, quality metrics, energy consumption, and maintenance costs that reflect overall paper die cutting machine health. Trend analysis of these parameters identifies gradual degradation patterns that might not be apparent during routine inspections.

Statistical analysis of maintenance data helps optimize preventive maintenance intervals and identify the most cost-effective replacement strategies for consumable components. Performance benchmarking against manufacturer specifications and industry standards provides objective measures of maintenance program effectiveness. Data-driven maintenance decisions maximize equipment availability while controlling maintenance costs and ensuring consistent production quality.

FAQ

How often should cutting dies be replaced in high-volume paper die cutting operations

Die replacement frequency depends on several factors including substrate type, cutting complexity, and production volume. Typically, cutting dies in high-cycle paper die cutting machine applications require evaluation every 50,000 to 100,000 cycles, with actual replacement based on cutting quality assessment rather than arbitrary schedules. Regular inspection of cut edge quality, measurement of cutting force requirements, and monitoring of waste generation patterns provide reliable indicators of die condition and replacement needs.

What are the most common causes of unexpected downtime in paper die cutting equipment

The primary causes of unplanned downtime include inadequate lubrication leading to bearing failures, improper die maintenance causing cutting quality issues, and neglected electrical connections resulting in control system malfunctions. Environmental factors such as dust accumulation and temperature extremes also contribute significantly to unexpected failures. Implementing comprehensive preventive maintenance programs addressing these common failure modes typically reduces unplanned downtime by 60-80% in industrial paper die cutting machine installations.

How can operators identify early signs of mechanical wear before complete component failure

Early wear indicators include gradual increases in operating noise levels, slight changes in cutting pressure requirements, minor variations in product positioning accuracy, and increased vibration during operation. Temperature monitoring reveals developing bearing problems, while regular measurement of critical dimensions identifies wear progression before failures occur. Training operators to recognize these subtle changes and document observations creates an early warning system that prevents catastrophic failures and reduces maintenance costs.

What safety considerations are essential during paper die cutting machine maintenance procedures

Safety protocols must include complete energy isolation using lockout/tagout procedures, verification of all moving parts in stopped position, and use of appropriate personal protective equipment during maintenance activities. Compressed air systems require safe depressurization procedures, and electrical work demands qualified personnel following established safety standards. Regular safety training for maintenance personnel and clear documentation of safety procedures ensure protection of workers while maintaining equipment reliability and performance standards.

Table of Contents

- Essential Daily Maintenance Procedures

- Weekly Calibration and Adjustment Procedures

- Monthly Deep Maintenance and Component Inspection

- Seasonal and Annual Maintenance Programs

- Preventive Maintenance Documentation and Record Keeping

-

FAQ

- How often should cutting dies be replaced in high-volume paper die cutting operations

- What are the most common causes of unexpected downtime in paper die cutting equipment

- How can operators identify early signs of mechanical wear before complete component failure

- What safety considerations are essential during paper die cutting machine maintenance procedures