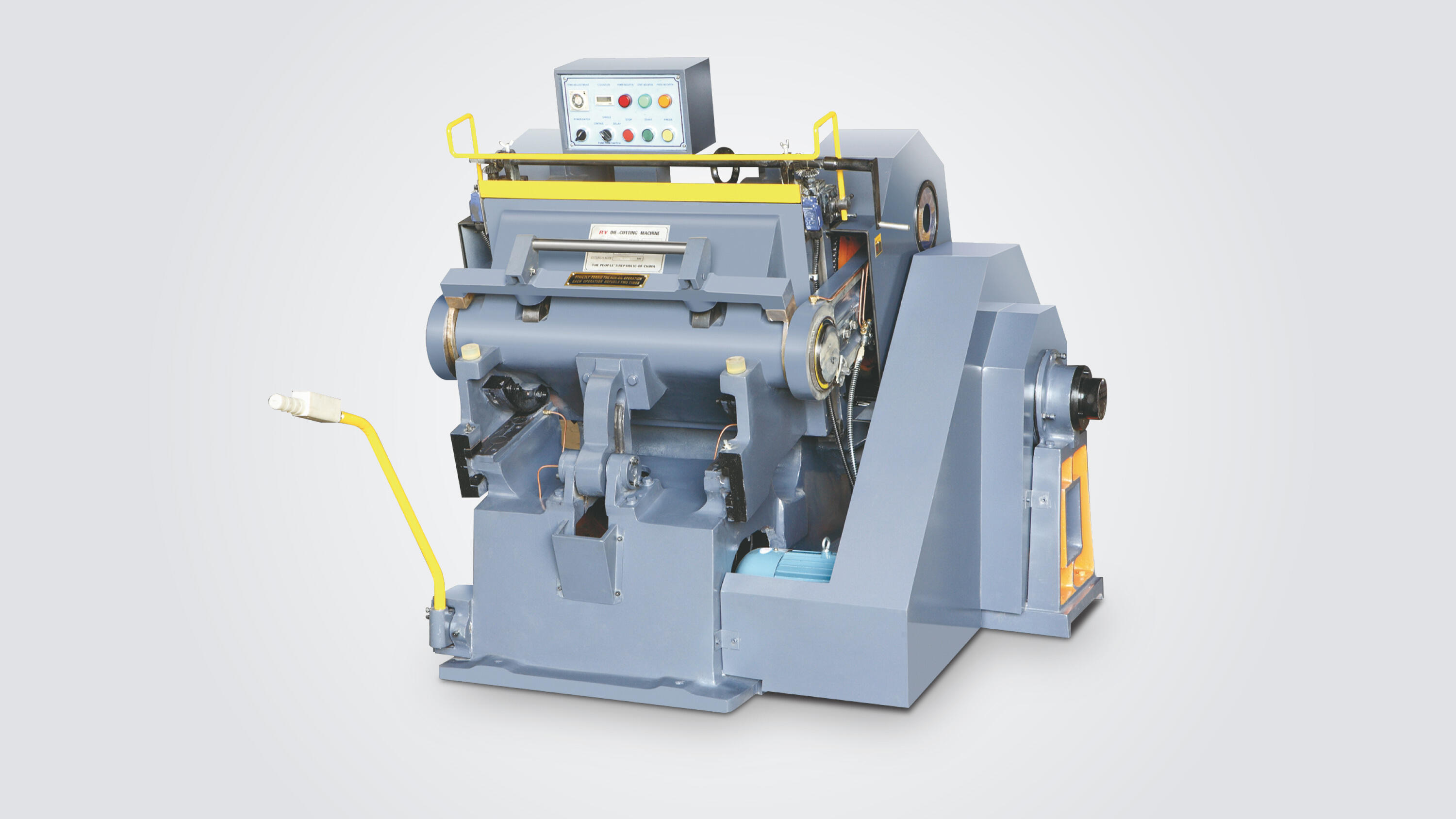

Būtinos kiekdienių priežiūros praktikos Didinimo mašinos

Inspekcijos ir valymo procedūros

Reguliariai tikrinant sukrėtimų mašinas, galima pastebėti problemas, kol jos vėliau netaps didesnėmis galvos skausmomis. Kasdien operatoriams reikia patikrinti pagrindines dalis, tokias kaip ritiniai, maitinimo mechanizmai ir slėgio reguliuotojai. Mažų problemų iš anksto aptikimas reiškia, kad juos reikia išspręsti, kol gamyba nebus sutrikdyta. Net taip svarbu ir valymo rutina. Visos mašinos turi būti švarios viduje ir išorėje, naudojant tinkamus švariklius, kurie nepažeistų subtilių dalių. Kai kuriose parduotuvėse naudinga įrašyti visus šiuos priežiūros darbus į darbo dienoraštį. Užrašant dalykus, technikai mato mašinos elgesio modelius per mėnesius ir metus, todėl vėliau, kai vėl atsiranda panašios problemos, išspręsti jas tampa daug lengviau. Dauguma įrangos gamintojų rekomenduoja šį dokumentą kaip standartinių priežiūros protokolų dalį.

Kalibravimas ir lygiavimo tikrinimai

Kad sukrėtimo mašina veiktų optimalu būdu, reikia tinkamai ją kalibruoti. Kas savaitę patikrinti, ar yra gamintojo rekomenduojama, padeda išlaikyti viską tinkamai veikiančiu. Kai dalys išsidėstys, tai pasirodys galutiniuose produktuose kaip defektai, kurių niekas nenori matyti. Todėl reguliarus stebėjimas yra toks svarbus kokybės kontrolei. Geros derinimo priemonės daro visą skirtumą, padedant parduotuvėms pasiekti tuos pramonės kriterijus, kurių joms reikia, kad liktų konkurencingos. Dokumentacija kartu su šiais patikrinimais veikia kaip ir įprastiniai patikrinimai. Užrašant kiekvieną pataisą, padarytą kalibravimo metu, arba pastebėdami, kada kažkas nukrypsta nuo įprastų nustatymų, sukuriamas popieriaus pėdas, į kurį vėliau gali kreiptis technikai. Šis įrašas padeda nustatyti modelius ir nustatyti problemas, kol jos netaps dideliais galvos skausmais gamybos linijoje.

Riebalavimo ir komponentų priežiūros gairės

Optimalus judančių dalių riebalavimo grafikas

Jei krepšimo mašina tinkamai tepama, ji išlaiko efektyvumą ir išlieka ilgesnė. Dauguma gamintojų siūlo tepti judančias dalis po 500 darbo valandų arba kartą per mėnesį, priklausomai nuo to, kas įvyks anksčiau, atsižvelgiant į mašinos darbą. Geras tepimo mazgas yra labai svarbus, nes klaidingas pasirinkimas gali pakenkti tiek mašinos veikimui, tiek ir jos veikimui. Ieškokite produktų, specialiai skirtų panašioms mašinoms. Kai kuriems komponentams riebalų naudojimas geresnis, o kitiems gali būti tinkamesnis lengvesni aliejai. Reguliariai tikrinant tepimą, išvengiama netikėto gedimo, kai gamyba baigiasi. Kai kuriose parduotuvėse sėkmingai atliekami paprastų tvarkaraščių rengimai, kai įvairiomis techninės priežiūros operacijomis užsiima skirtingi darbuotojai.

Rulo ir kraštutėlių priežiūros strategijos

Sulipimo mašinų valcavimo valcavimo valcavimo valcavimo valcavimo valcavimo valcavimo valcavimo valcavimo valcavimo valcavimo valcavimo valcavimo valcavimo valcavimo valcavimo valcavimo valcavimo valcavimo valcavimo valcavimo valcavimo valcavimo valca Dauguma technikų rekomenduoja patikrinti šias dalis bent kartą per mėnesį, nes nusidėvėjusios dalys tikrai paveiks visą mašiną. Kai dalys pradeda rodyti nusidėvėjimo požymius, kaip antai užtraukimas ar ištraukimas, geriausia jas pakeisti, kol viskas darosi blogiau. Taip pat svarbu tvarkyti namus, kad viskas būtų tvarkinga. Dūmų kaupimasis aplink guolius ir ritinius turi būti reguliariai pašalinamas naudojant minkštus audinius ir patvirtintus tirpiklius. Kai kurie žmonės prisiekia suspaustu oru, kad patenka į siauras patalpas, kur kaupia purvą. Paprastas stebėjimo grafikas padeda pastebėti problemas, kol jos netaptų didžiuliu galvos skausmu. Pasirūpinkite, kad veikimo metu nebūtų neįprastų triukšmo ar vibracijų, nes tai dažnai rodo, kad reikia atkreipti dėmesį į problemą.

Procedūros jungčių priežiūrai ir keitimui

Tempiamosios technikos nuolatiniam veikimui

Kad būtų galima gerokai sumažinti ir išlaikyti efektyvumą, labai svarbu, kad peiliai būtų nuolat veikiantys. Dauguma žmonių mano, kad įdiegiant rutiną, kai jie įskaudina po maždaug 2000 pjūvių, gerai veikia, nors tai gali skirtis priklausomai nuo to, kokio tipo medžiagą dažniausiai pjaunama. Taip rūpinantis peiliu, jis ilgiau tarnaus ir nepalieka tų piktų, nuobodus dėmės. Kitas svarbus veiksnys yra tinkamos šildymo įrangos pasirinkimas konkrečioms peilių tipoms. Pavyzdžiui, karbido lazdams reikia skirtingo apdorojimo, palyginti su greitojo plieno lazdomis. Jei taip elgiamės, gauname geresnių rezultatų ir mažiau galimų brangų lazdų pažeidimų. Įrašyti, kada įostrinamas, kartu su užrašomis apie tai, kaip tą laiką jautėsi peilis, vėliau suteikia vertingą informaciją. Pramonės duomenys rodo, kad įmonės, kurios laikosi reguliarių priežiūros tvarkaraščių, paprastai turi mažiau blogų nuolaidų, ką pasakys kiekvienas, kuris valdo pjaustymo operacijas.

Šaukštų sablonų ir pažeidimų ženklų nustatymas

Kad gamyba veiktų be kliūčių, reikia reguliariai tikrinti peilius, ar jie nesuprantė ar nepažeisti. Pasirūpinkite, kad peiliai nebūtų nuobodu arba nesukeltų mažų dribsnių, nes šios problemos gali pabloginti pjovimo kokybę. Mes nustatėme, kad greitas vizualinis patikrinimas kas savaitę gana gerai padeda nustatyti problemas, kol jos dar nėra pablogusios. Darbuotojų mokymas pastebėti, kada raukšlės neaiškėja teisingai arba kai mašinos pradeda dirbti sunkiau nei įprasta, taip pat daro visą skirtumą. Kai mes sukursime sistemą, kurioje žmonės iš karto pasakys, jei pastebės, kad kažkas negerai su peiliu, tai sumažins netikėtus sustojimus. Tiesiog greitai išspręsti peilių problemas, išlaikysime mūsų produkciją nuoseklią visose partijose, kas labai svarbu, kai klientai tikisi aukščiausios kokybės produkto.

Bendrųjų krituliavimo mašinų problemų sprendimas

Smulkmenų ir sutapimo problemų eliminavimas

Sūkymo mašinose dažnai susiduria su raukšlėjimu ir išsisakymu, dėl kurių gamyba nesuderinama su partijomis. Kai susiduriama su raukšlėmis, operatorius pirmiausia turi ištirti, kas iš tikrųjų jų sukelia. Dažniausiai kaltininkas yra netinkamas pašarų kiekis arba medžiagos, kuriose yra per daug drėgmės, kurios vis dar yra po džiovinimo. Šių pagrindinių dalykų išaiškinimas padeda išlaikyti pastovią produkto kokybę per visą gamybos laikotarpį. Jei susiduria su klaidingais suderinamumo atvejais, yra tikslinga sukurti išsamų klaidų sprendimo patikrinimo sąrašą, nes dauguma atvejų atsiranda dėl mašinos nusidėvėjusių dalių arba įrengimo klaidų. Reguliarus techninės priežiūros patikrinimas turėtų apimti visus judančius komponentus, o derinimo patikrinimas turi būti atliekamas keliose gamybos linijos vietose. Darbuotojų mokymo programos neturėtų būti tik teorinės. Praktiškai rengiami seminarai, kuriuose technikai praktikuoja, kaip nustatyti abiejų problemų ankstyvąsias įspėjamąsias požymias ir išmokti tinkamus reguliuojimo būdus, padės išvengti brangiai kainuojančių darbo laiko.

Sprendžiant medžiagų susijusius išnaudojimo ir nuostolio klausimus

Dirbant su skirtingomis medžiagomis, kurios laikui bėgant nusidėvėja įrangą, operatoriams reikia koreguoti jų įrengimo parametrus atsižvelgiant į tai, ką jie iš tikrųjų apdoroja, nes tam tikros medžiagos tikrai daro įtaką mašinų gyvavimo trukmei. Iš tikrųjų, iš tikrųjų, iš tikrųjų, iš tikrųjų, iš tikrųjų, iš tikrųjų, iš tikrųjų, iš tikrųjų, iš tikrųjų, iš tikrųjų, iš tikrųjų, iš tikrųjų, iš tikrųjų, iš tikrųjų, iš tikrųjų, iš tikrųjų, iš tikrųjų, iš tikrųjų, iš tikrųjų, iš tikrųjų, iš tikrųjų, iš tikrųjų, iš tikrųjų, iš tikrųjų, iš tikrųjų, iš tikrųjų, Atlikti situacijas, kai konkrečios medžiagos sutrikdė mašinos veikimą, suteikia vertingą supratimą apie tai, kokių pokyčių gali prireikti eksploatuoti. Jei norite sumažinti dėvėjimo problemas ir išlaikyti mašinų sklandų darbą be nuolatinių gedimų, reikia pritaikyti techninės priežiūros planus pagal faktines medžiagas, kurios naudojamos sistemoje.

Ilgalaikis saugojimas ir profesionalus aptarnavimas

Planuojami profesionalaus aptarnavimo intervalai

Reguliarus profesionalias apdirbimas sukabinimo mašinoms daro didelę įtaką jų gyvavimo trukmei. Dauguma specialistų rekomenduoja juos apžiūrėti maždaug kas šešis mėnesius. Šie įprasti patikrinimai užkerta kelią dideliems problemų iškilimui ir užtikrina, kad mašina veiktų taip, kaip turėtų. Atgal pažiūrėjus į ankstesnius aptarnavimo įrašus, galima nustatyti, ar tie šešių mėnesių intervalai tikrai tinka kiekvienam konkrečiam įrenginiui. Kartais reikia keisti, kiek dažnai kasdien naudojate. Kai įsivežiojate sertifikuotus technikus, yra dar viena nauda, išskyrus tai, kad jūs tiesiog taisite dalykus, kurie nėra teisingi. Patyrę technikai dažnai pastebi galimybes tobulėti, kurios anksčiau nebuvo akivaizdžios. Tokia perspektyvi požiūris apsaugo nuo netikėtų avarijų, kurios gali visiškai sustabdyti gamybą. Kompanijos, kurios laikosi tvarkaraščio, paprastai sutaupys pinigų, nes nebus reikalingas brangus neatidėliotinas remontas. Be to, visi miega geriau žinodami, kad jų įranga lieka patikima per didelius ir plonesnius.

Duomenų įrašymas prevenciniam priežiūrai

Geras įrašų saugojimas labai svarbus prevencinio priežiūros darbams. Kai mes užrašome, kas daroma atliekant techninės priežiūros patikrinimus, kai keičiamos dalys, ir įrašus iš reguliarių patikrinimų, viskas išlieka organizuota, kad žinotume, kas atsitiko kada. Čia taip pat labai padeda skaitmeninės sistemos, kurios palengvina senų įrašų paiešką ir laiko tendencijų nustatymą, kuri mums praneša, kada kažkas gali greitai klysti. Atsimintinai pažvelgus į praeities įrašus, galima pastebėti problemas, kol jos dar nesudėtino. Pavyzdžiui, mūsų susilenkimo mašinos, jei tam tikros dalys neveiktų pagal žurnalo taisykles, mes pradėtume jas tikrinti dažniau arba pakeisti anksčiau nei vėliau. Visų šių dalykų sekimas leidžia geriau planuoti techninę priežiūrą ir leidžia mūsų mašinoms dažniausiai veikti sklandžiai. Tvirta sekimo sistema reiškia, kad mes paprastai taisome dalykus prieš tai, kai įvyksta gedimai, o ne po to, kai įvyksta įvykiai.

DUK

Kaip dažnai turėčiau tikrinti ir išvalyti savo įkaitinimo mašiną?

Rekomenduojamos kasdieninės inspekcijos ir išsamus valymo grafikas, kad būtų palaikoma optimali našumas.

Kokia yra kalibravimo ir lygiavimo patikros svarba?

Kalibravimas užtikrina, kad jūsų mašina veiktų pagal gamintojo specifikacijas, o lygiavimo patikros prevencijuotų išėjimo defektus.

Kokiu intervalu reikia gaminantįją dalis deginti?

Judantys elementai turėtų būti guliota kas 500 valandas veikimo arba mėnesiniu tarpu, atsižvelgiant į naudojimo intenzityvumą.

Kada reikia patikrinti rituliukus ir pakablius išlaidoms ir sužalojimams?

Rekomenduojamos mėnesinės inspekcinės, kad būtų nustatyti galimi degradacijos ženklai ir palaikoma našumas.

Kokie yra lopų išlaidos ženklai, kuriuos turėčiau stebėti?

Rodikliai apima tylumą, šluostas ir prastėjusią pjovimo kokybę, todėl būtinos savaitinės vizualinės inspekcinės.