Advanced Cutting Technology

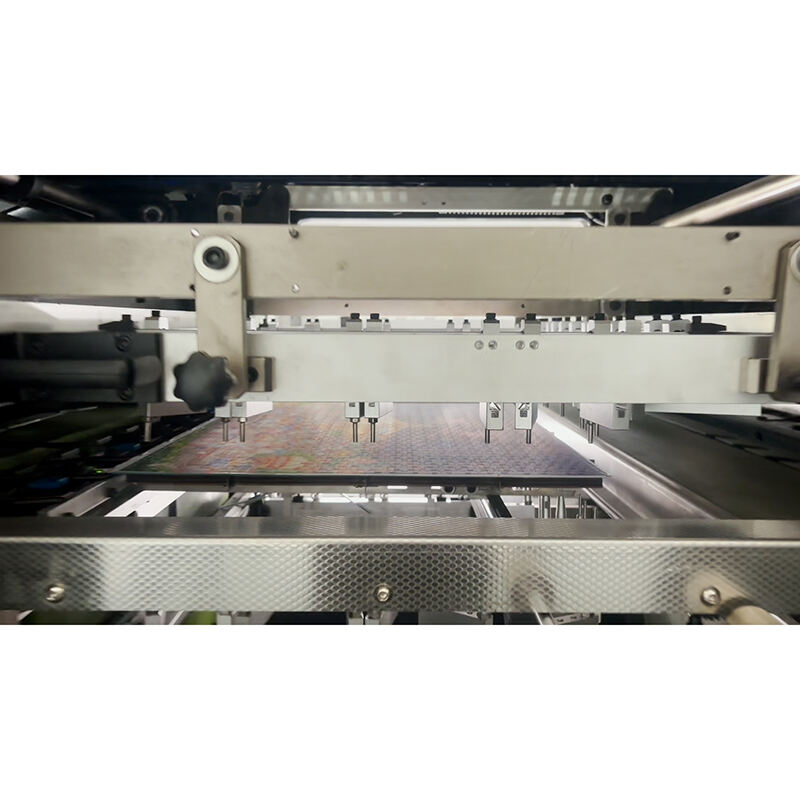

The cutting mechanism employed in the jigsaw puzzle cutting machine represents the pinnacle of precision manufacturing technology. Utilizing a combination of high-powered laser systems and advanced die-cutting capabilities, the machine achieves unprecedented accuracy in piece creation. The cutting head moves with microscopic precision, guided by sophisticated motion control algorithms that maintain consistent cutting depths and speeds. This technology ensures clean, precise edges on every piece, eliminating common issues like fraying or incomplete cuts. The system automatically adjusts cutting parameters based on material properties, ensuring optimal results across different substrates. The cutting mechanism also incorporates automatic tool wear compensation, maintaining consistent quality throughout extended production runs.