Advanced Automation and Precision Control

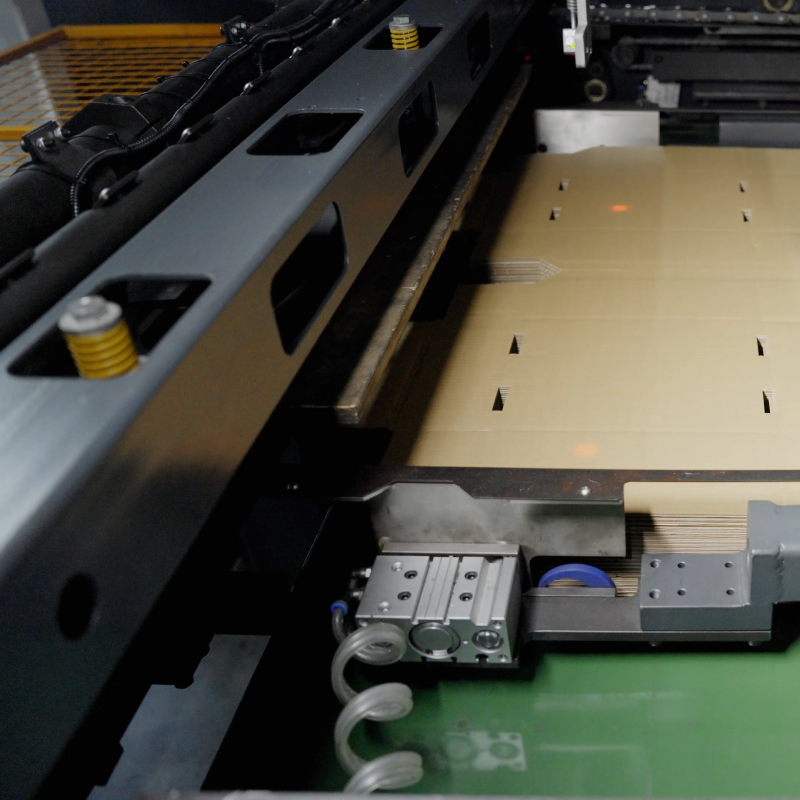

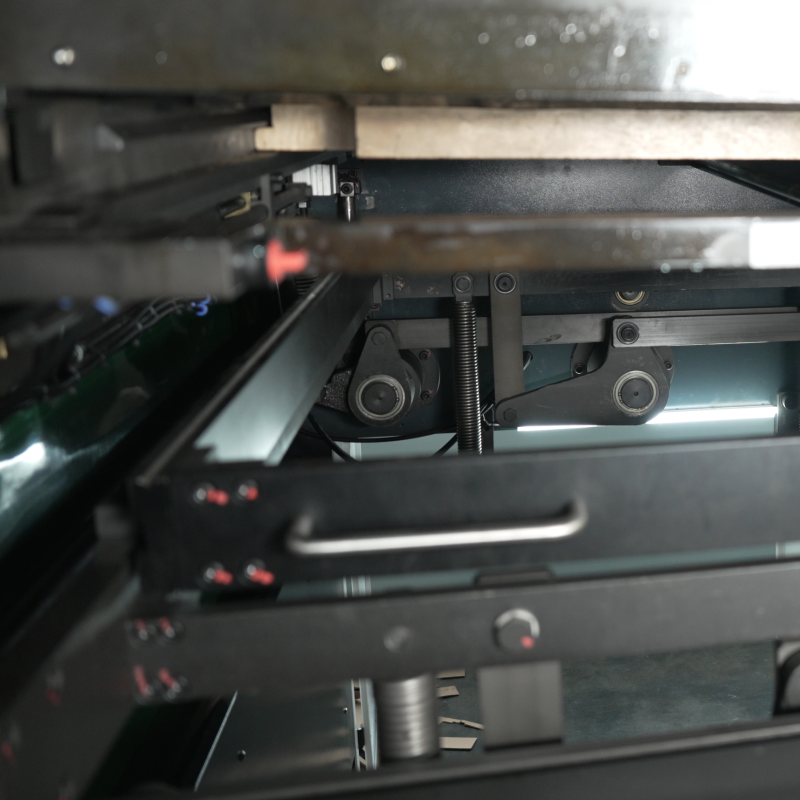

The machine die cut factory's automation system represents the pinnacle of manufacturing technology, incorporating sophisticated sensors and control mechanisms that ensure unparalleled precision in cutting operations. This advanced system continuously monitors and adjusts cutting parameters in real-time, maintaining optimal performance throughout production runs. The precision control extends to material handling, where automated systems manage material flow with minimal human intervention, reducing errors and ensuring consistent quality. The integration of computer-aided manufacturing systems enables precise coordination between different production stages, maximizing efficiency and minimizing waste. The automated quality control system employs high-resolution cameras and sensors to inspect each cut piece, automatically identifying and removing defective items from the production line.