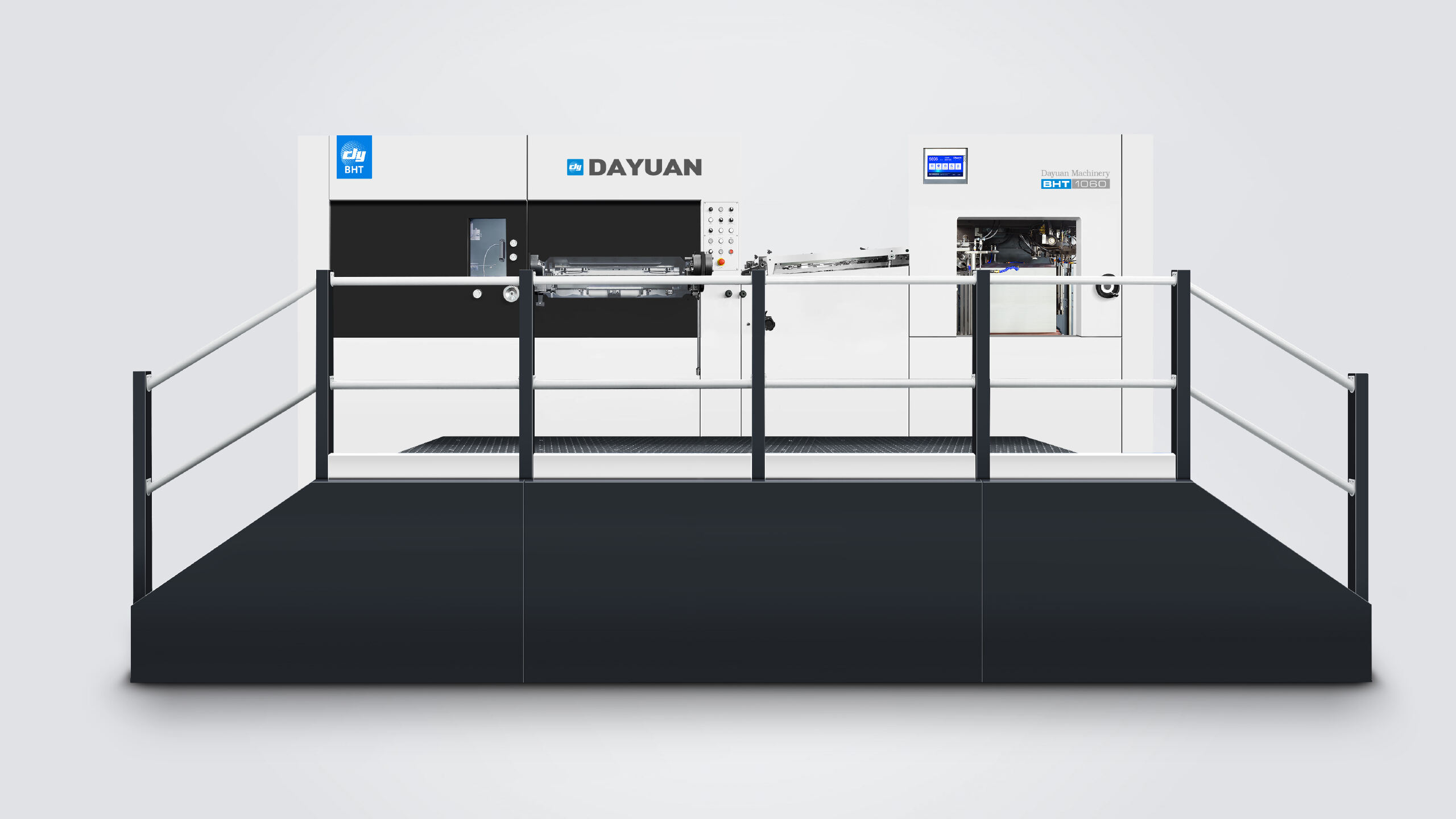

BHT-1060/1060A/1060AR

Automatic Die Cutting Machine

- Excellent precision, durability and stability

- Maximum speed: 7500 sheets/h

- Maximum working pressure: 600T

- Overview

- Technical Parameters

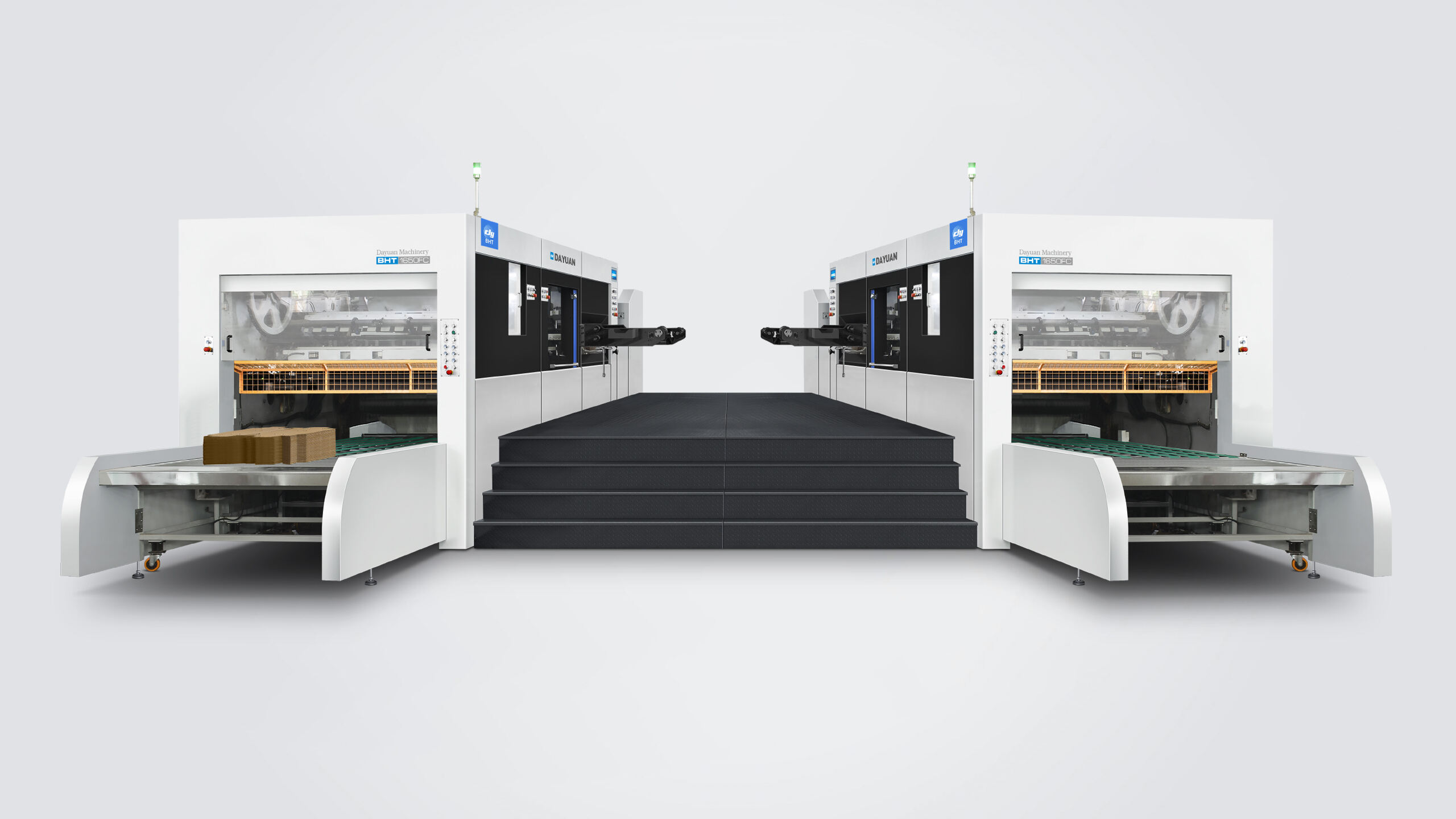

- Related Products

- FAQ

Product Description

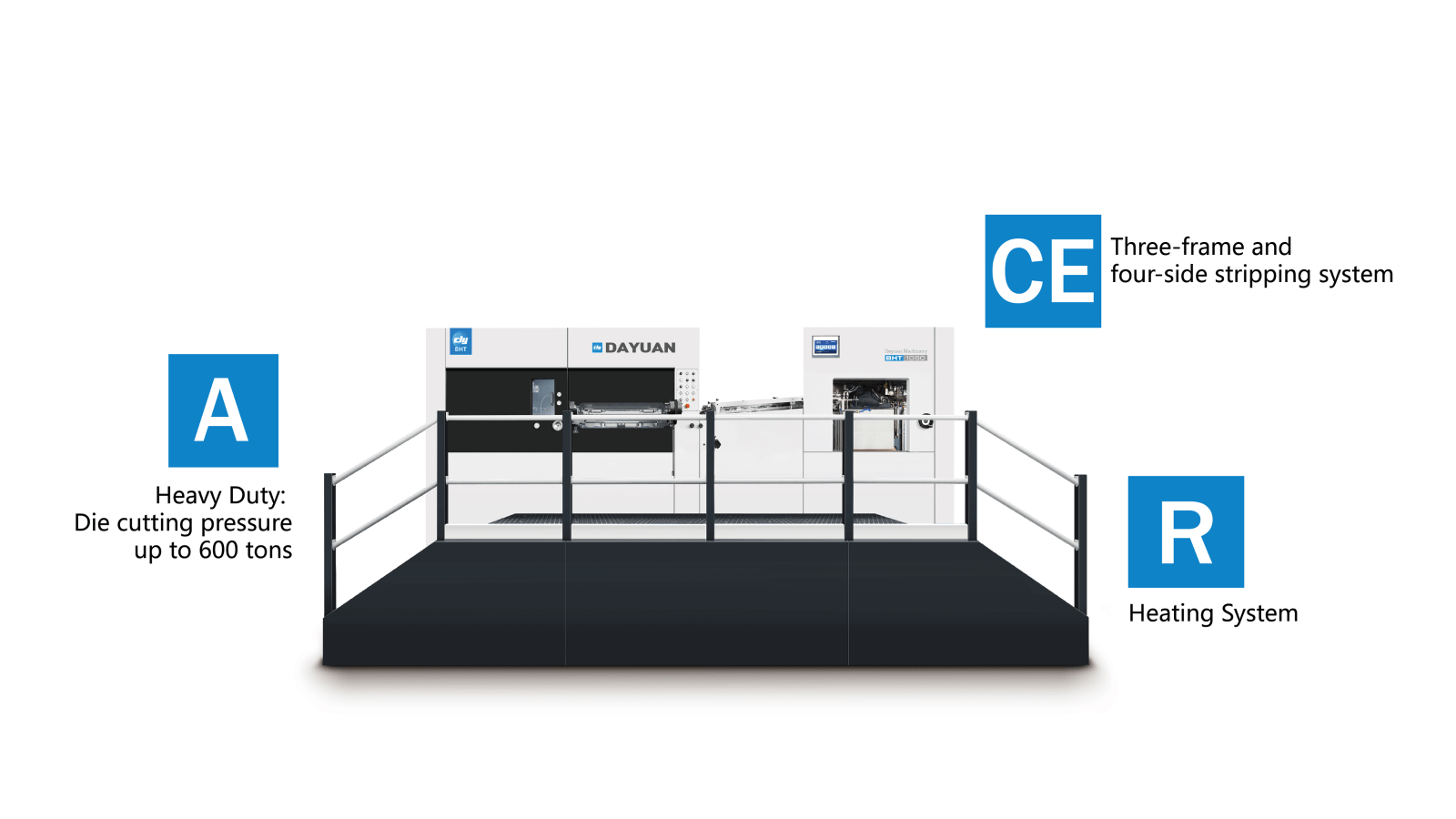

For long-term partnerships, precision and equipment durability are paramount in automatic flatbed die cutting machine. Dayuan BHT-1060/1060A/1060AR Automatic Die Cutting Machine delivers exceptional accuracy for superior die cutting quality, while offering customizable configurations to match your production needs—boosting efficiency and reducing operational costs.

Outstanding Productivity:

• Maximum speed: 9,000 sheets/hour

• Maximum pressure: 600 tons

• Supports quick setup and fast changeover with microadjustment devices.

• Automatic non-stop roll-up curtain type delivery device.

Superior Quality:

• Die cutting accuracy: ±0.075mm

• Heavy duty/heating system available(optional).

• Turbo variable-speed drive technology ensures clean cuts with no burrs or loose sheets, guaranteeing flawless output.

• Carbon fiber gripper bars (lightweight yet ultra-strong) maintain stability even at high speeds.

Excellent Cost Efficiency:

• Robust cast-iron construction ensures stability.

• Intuitive HMI (human-machine interface) for user-friendly, error-free operation.

• Complete spare parts supply chain ensures worry-free after-sales support.

|

|

|

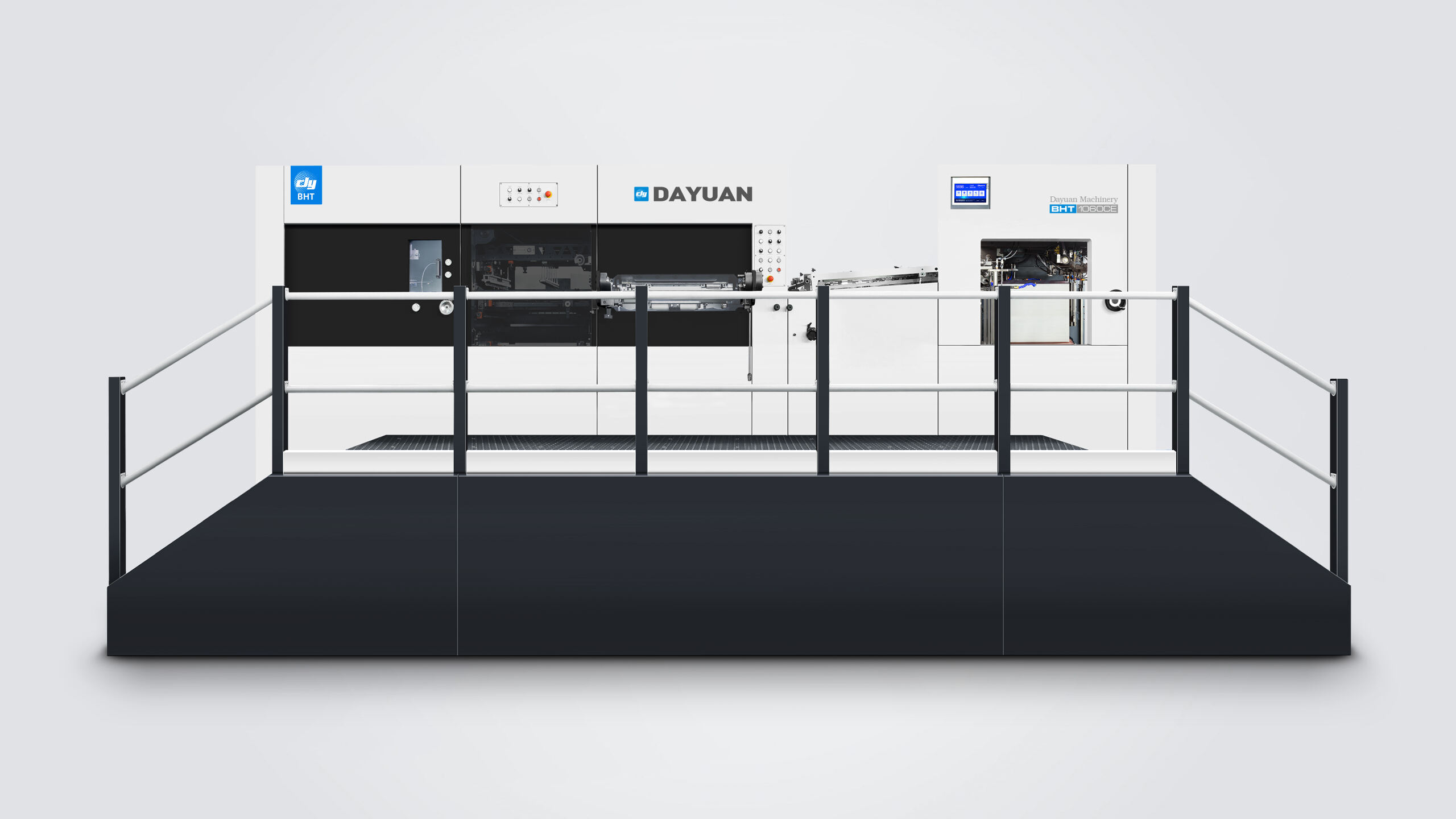

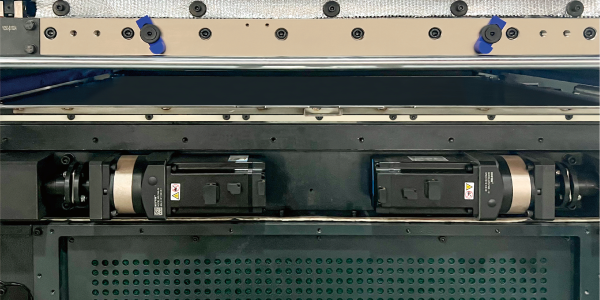

| Feeder(4 suction and 6 delivery) |

Ultrasonic double sheet detector |

Paper conveying unit |

|

|

|

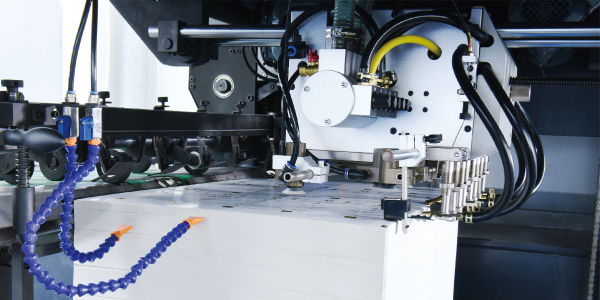

Timing belt driven device |

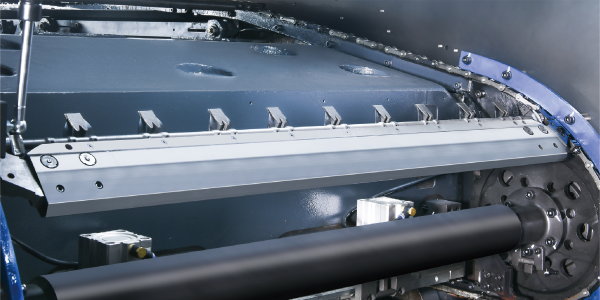

Carbon fiber gripper bar |

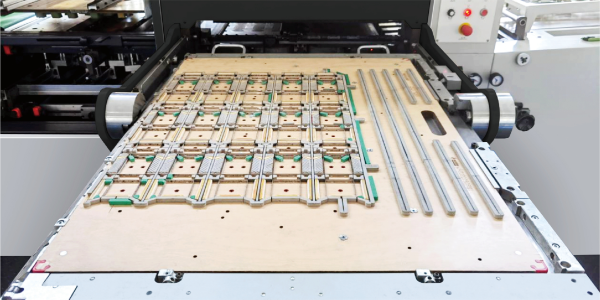

Micro-adjustable die cutting plate |

|

|

|

Micro-adjustable frame with quick locking device |

Servo controlled gripper bar positioning device |

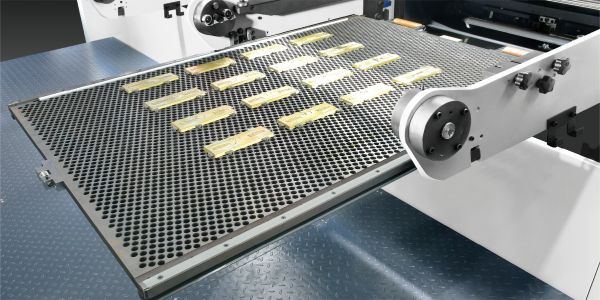

Micro-adjustable honeycomb plate |

|

|

|

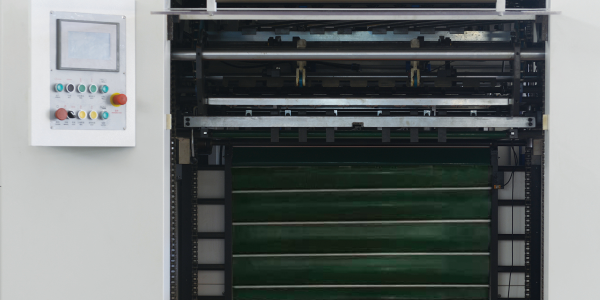

Non-stop roll-up curtain type paper delivery device |

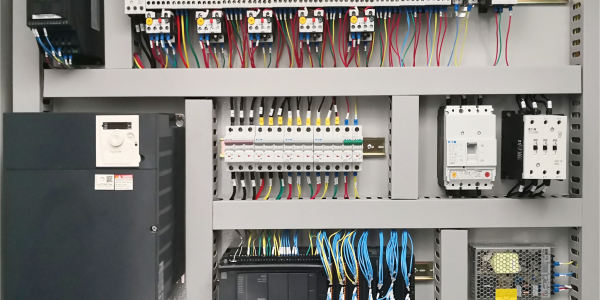

Electrical unit |

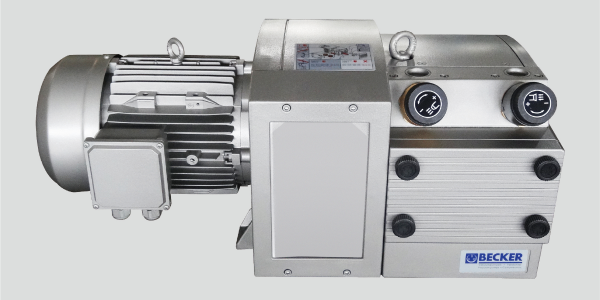

Germany vacuum pump |

|

|

|

Auto lubrication system |

Main unit cooling/lubrication mechanism |

Technical Parameters

|

Model |

BHT-1060 |

BHT-1060A |

BHT-1060AR |

|

Maximum Sheet Size |

1060×760mm |

1060×760mm |

1060×760mm |

|

Minimum Sheet Size |

400×350mm |

400×350mm |

400×350mm |

|

Maximum Cutting Size |

1060×745mm |

1060×745mm |

1060×745mm |

|

Maximum Embossing Area |

/ |

/ |

1060×745mm |

|

Minimum Gripper Margin |

9-17mm |

9-17mm |

9-17mm |

|

Cutting Rule Height |

23.8mm |

23.8mm |

23.8mm |

|

Inner Chase Size |

1080×790mm |

1080×790mm |

1080×790mm |

|

Stock Range |

Cardboard: 80-2000g/m²,0.1-2mm |

Cardboard: 80-2000g/m²,0.1-2mm |

Cardboard: 80-2000g/m²,0.1-2mm |

|

Die Cutting Accuracy |

≤±0.075mm |

≤±0.075mm |

≤±0.075mm |

|

Embossing Accuracy |

/ |

/ |

≤±0.075mm |

|

Max.Cutting Force |

300T |

600T |

600T |

|

Max.Working Speed |

9000s/h |

8000s/h |

8000s/h |

|

Maximum Feeder Pile Height |

1630mm |

1630mm |

1630mm |

|

Maximum Delivery Pile Height |

1480mm |

1480mm |

1480mm |

|

Electric-heated System |

/ |

/ |

20 Heating zones,40-180℃ Adjustable |

|

Main Motor Power |

15KW |

15KW |

15KW |

|

Full Load Wattage |

23KW |

23KW |

35KW |

|

Air Requirement |

0.6-0.7MPa,≥0.37m³/min |

0.6-0.7MPa,≥0.37m³/min |

0.6-0.7MPa,≥0.37m³/min |

|

Net Weight of Machine |

19T |

21T |

21.5T |

|

Machine Dimensions(L×W×H) |

6705×4466×2301mm |

6705×4616×2301mm |

6705×4616×2301mm |

|

Machine Dimensions(Including Die Preloader)(L×W×H) |

6705×5366×2301mm |

6705×5516×2301mm |

6705×5516×2301mm |