BHT-1500FC/1650FC/1900FC/2100FC

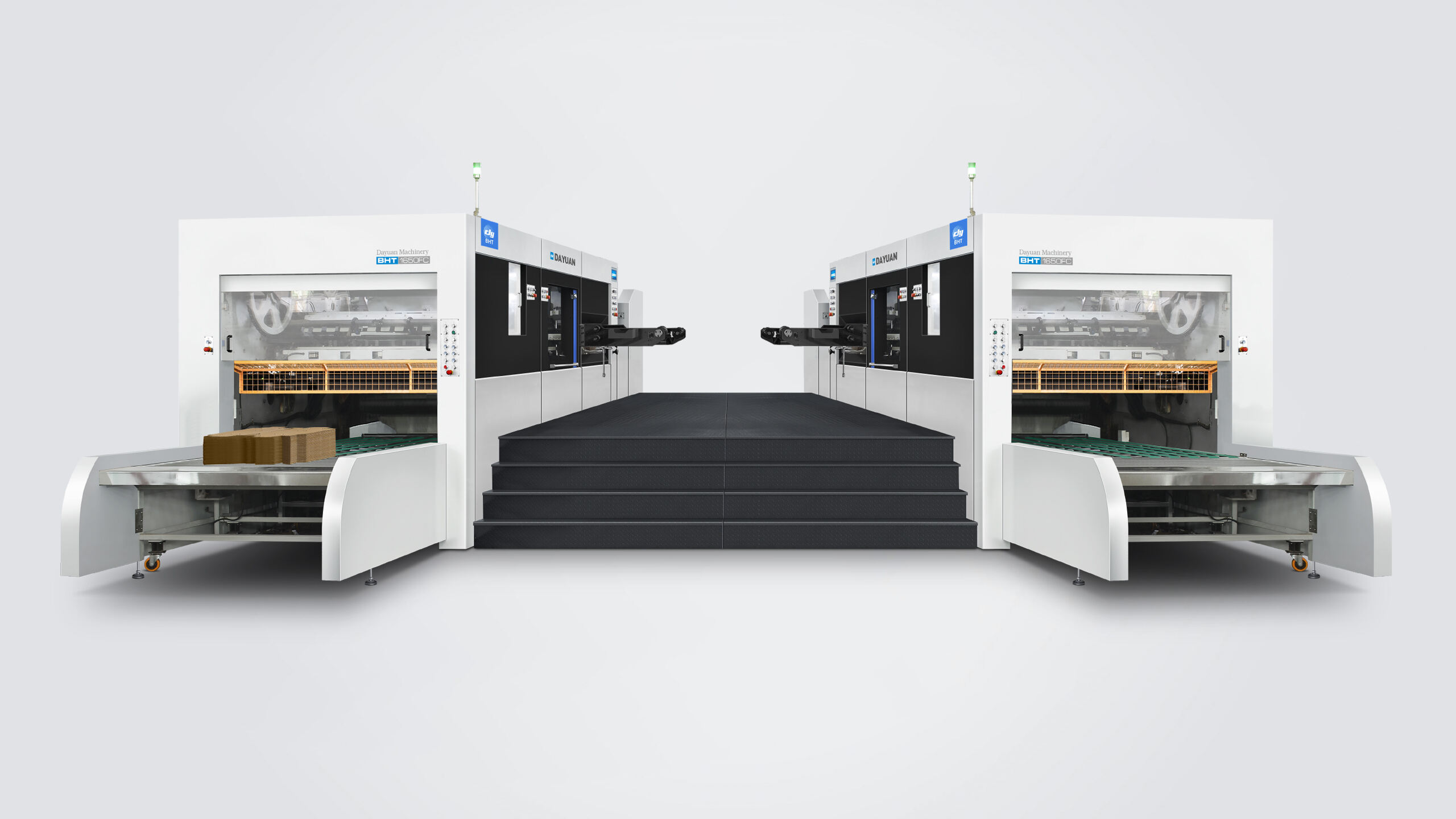

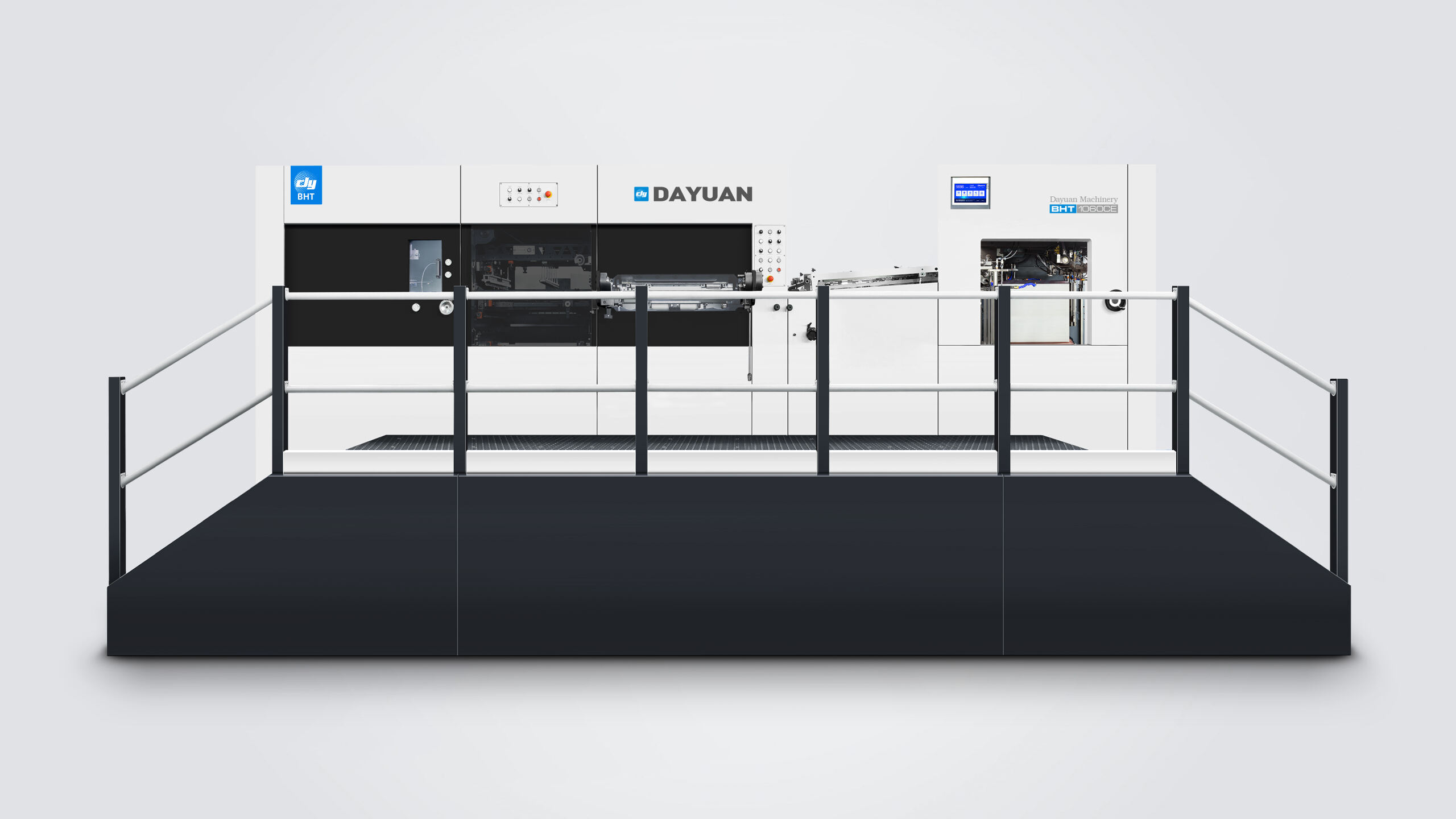

Mirror Machines Dual Diecutter Working Station

- Saving the labor cost and 25% floor space

- Sharing all the die cutting molds and frame

- Convenient anomaly detection and troubleshooting

- Overview

- Area Saving

- Technical Parameters

- Related Products

- FAQ

The Advantage of Mirror Machines Dual Diecutter Working Station

This innovative mirror die cutter system features two automatically operated machines positioned face-to-face with aligned feeding and delivery sections, enabling shared pedal control while minimizing floor space requirements for optimized facility planning. Requiring just one operator per shift, the mirrored configuration provides complete visual monitoring of both units within a single sightline - allowing immediate anomaly detection and troubleshooting to maintain peak production quality. By combining space efficiency with operational oversight and reduced labor costs, this dual-handling configuration represents the ultimate solution for precision die-cutting operations.

Area Saving

|

|

2 Regular Machines Floor Space |

Mirror Machines Floor Space |

Total Space Saved |

|

With Chase Loader |

197.3m² |

148.5m² |

48.8m² |

|

Without Chase Loade |

172.2m² |

142.8m² |

27.4m² |

Because the same foot pedal is shared, the intermediate channel (at least 2×10 meters) when the two machines are placed separately, can save 2×10=20m2 of plant occupation area.

Technical Parameters

|

Model |

BHT-1500FC/1500EFC |

BHT-1650FC/1650EFC |

BHT-1900FC/1900EFC |

BHT-2100FC/2100EFC |

|

Maximum Sheet Size |

1520×1100mm |

1650×1200mm |

1900×1400mm |

2100×1600mm |

|

Minimum Sheet Size |

480×480mm |

650×500mm |

650×500mm |

750×650mm |

|

Maximum Cutting Size |

1500×1100mm |

1630×1180mm |

1880×1380mm |

2080×1580mm |

|

Minimum Gripper Margin |

9-17mm |

9-17mm |

9-17mm |

9-17mm |

|

Minimum Width of Cuts |

10-18mm |

10-18mm |

10-18mm |

10-18mm |

|

Cutting Rule Height |

23.8mm |

23.8mm |

23.8mm |

23.8mm |

|

Inner Chase Size |

1600×1146mm |

1670×1230mm |

1920×1430mm |

2190×1629mm |

|

Stock Range |

Corrugated board: ≤9mm,F,E,B,C,A and AB corrugated paper |

Corrugated board: ≤9mm,F,E,B,C,A and AB corrugated paper |

Corrugated board: ≤9mm,F,E,B,C,A and AB corrugated paper |

Corrugated board: ≤9mm,F,E,B,C,A and AB corrugated paper |

|

Die Cutting Accuracy |

≤±0.15mm |

≤±0.2mm |

≤±0.2mm |

≤±0.2mm |

|

Max.Cutting Force |

400T |

400T |

450T |

450T |

|

Max.Working Speed |

6000s/h |

6000s/h |

5000s/h |

4000s/h |

|

Maximum Delivery Pile Height |

1500mm |

1500mm |

1500mm |

1500mm |

|

Main Motor Power |

18.5KW |

18.5KW |

18.5KW |

22KW |

|

Full Load Wattage |

38KW |

38KW |

40KW |

47KW |

|

Air Requirement |

0.6-0.7MPa,≥1m³/min |

0.6-0.7MPa,≥1m³/min |

0.6-0.7MPa,≥1m³/min |

0.6-0.7MPa,≥1m³/min |

|

Net Weight of Machine |

76T / 78T |

80T / 82T |

92T / 94T |

102T / 104T |

|

Machine Dimensions (Stacking Delivery) (L×W×H) |

9887×11000×2800mm |

10344×11940×2876mm(FC) |

11853×13120×2972mm(FC) |

14370×14320×2972mm |

|

10187×11940×2876mm(EFC) |

11652×13120×2972mm(EFC) |

|||

|

Machine Dimensions (Batch Delivery Conveying) (L×W×H) |

11400×11000×2800mm |

12049×11940×2876mm(FC) |

13690×13120×2972mm(FC) |

15870×14320×2972mm |

|

11892×11940×2876mm(EFC) |

13489×13120×2972mm(EFC) |