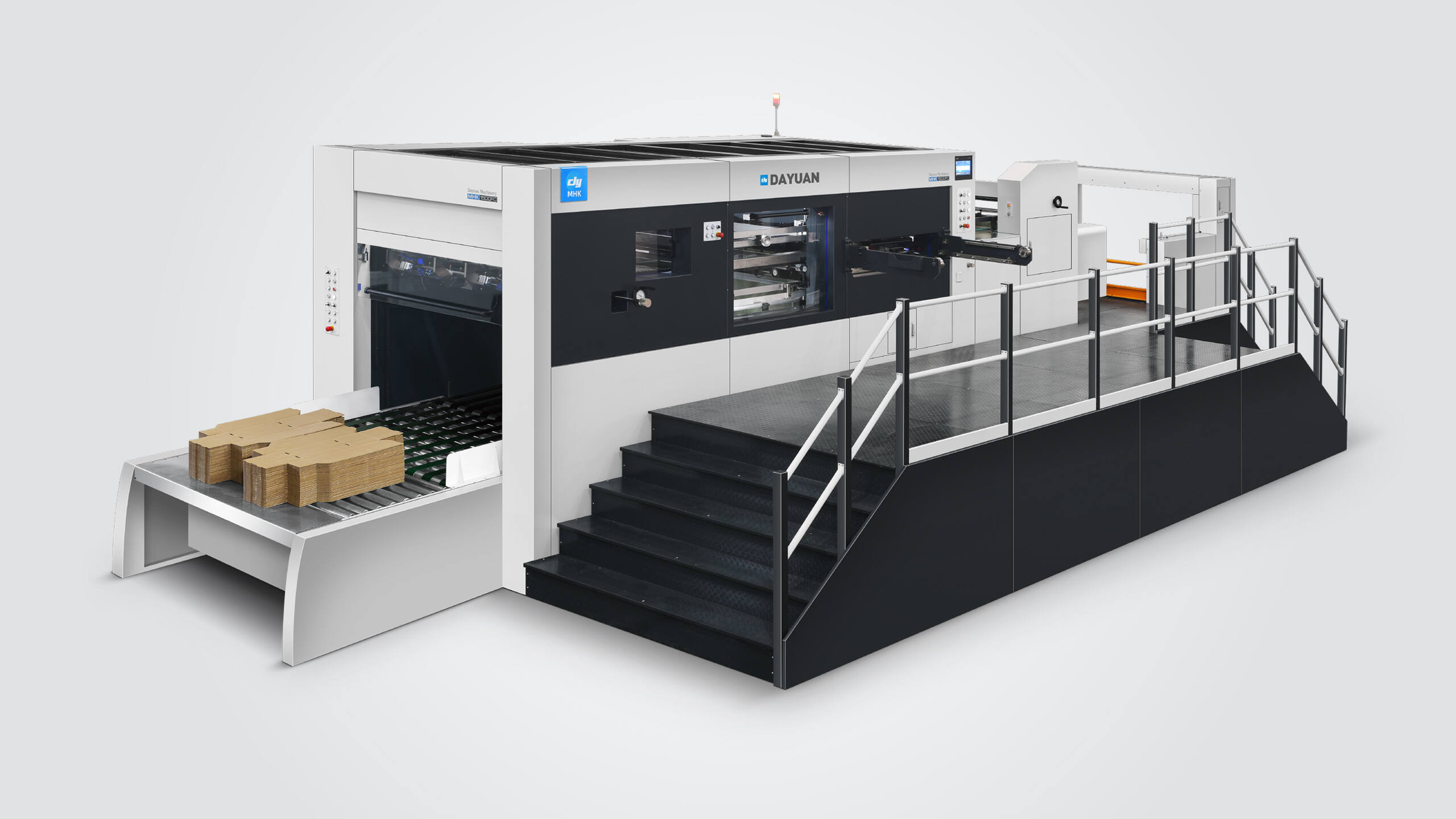

MHK-820/1050/1180

Automatic Die Cutting Machine

- Maximum speed: 7,500 sheets/hour; Maximum pressure: 600 tons

- 50% faster plate-changing than industry standards

- Boost your production efficiency while reducing operating costs

- Overview

- Technical Parameter

- Related Products

- FAQ

Product Description

Precision, durability and stability are crucial in automatic flatbed die cutting machine. Dayuan MHK-series Automatic Die Cutting Machine has multiple sheet size options ranging from 820×600mm to 1500×1110mm, maintaining precision even at maximum operating speeds to significantly boost your production efficiency while reducing operating costs. We offer customizable configurations that allow flexible functional adjustments to meet your specific production needs, enabling rapid productivity gains with our automatic die cutter machine.

Outstanding Productivity:

• Maximum speed: 7,500 sheets/hour

• Maximum pressure: 600 tons

• 50% faster plate-changing significantly boosts productivity and extends uptime

• Automatic non-stop roll-up curtain type delivery device.

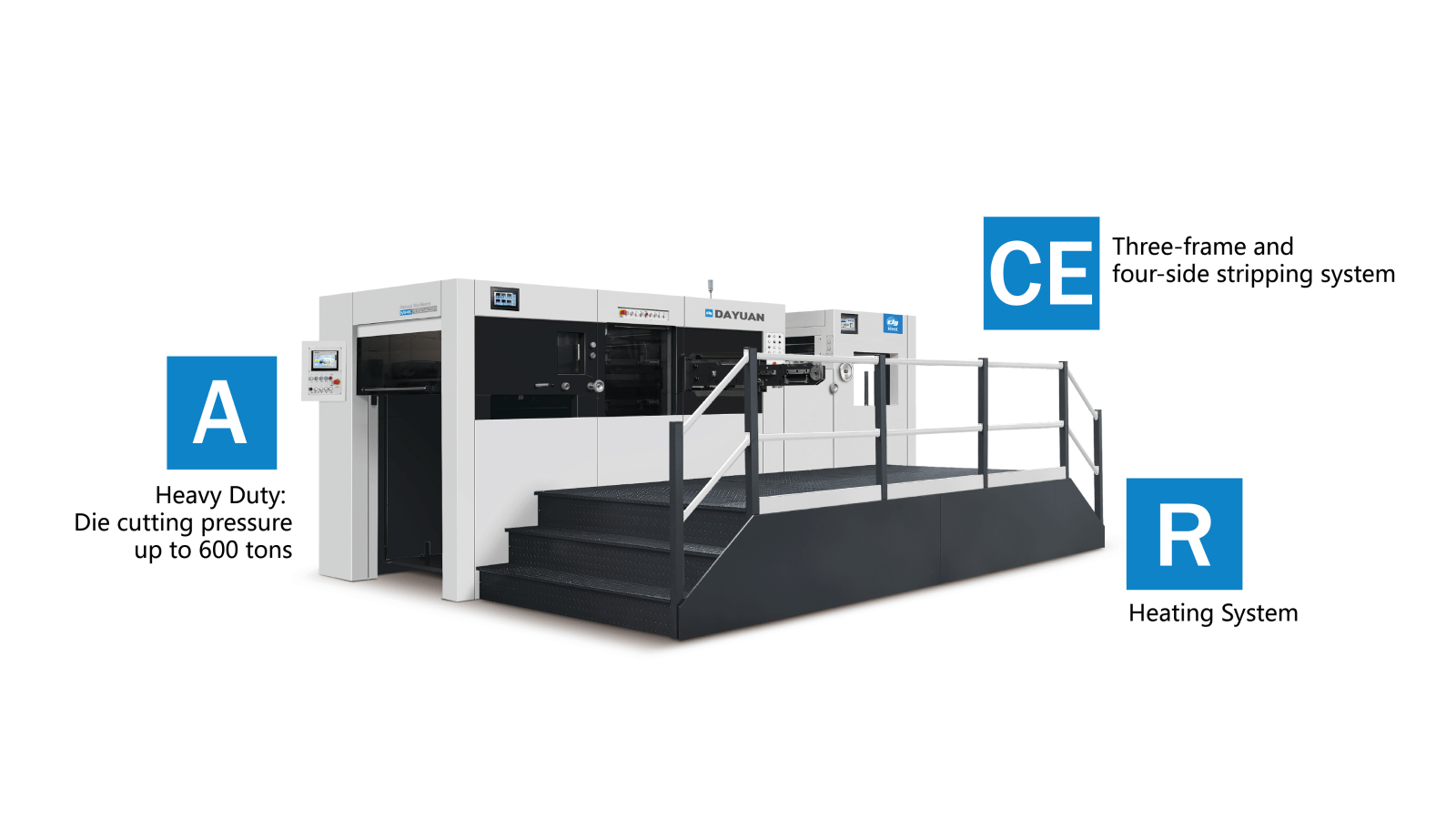

Superior Quality:

• Servo controlled gripper bar positioning device(Invention Patent)

• Heavy duty/heating system available(optional).

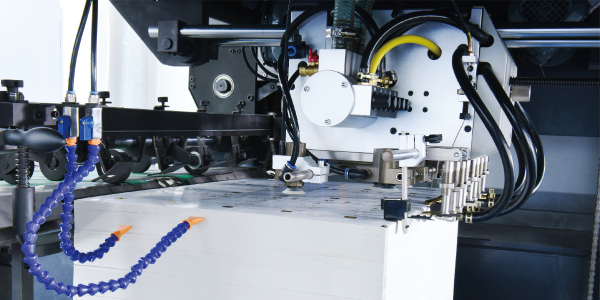

• Equipped with an automatic oil supply system and precision temperature-controlled lubrication (cooling) system, it maintains optimal oil temperature for consistent production.

Excellent Cost Efficiency:

• Intuitive HMI (human-machine interface) for user-friendly, error-free operation.

• Complete spare parts supply chain ensures worry-free after-sales support.

|

|

|

Feeder(4 suction and 6 delivery) |

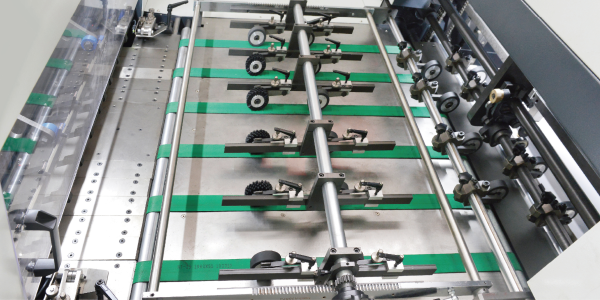

Paper conveying unit |

Front gauge & side gauge |

|

|

|

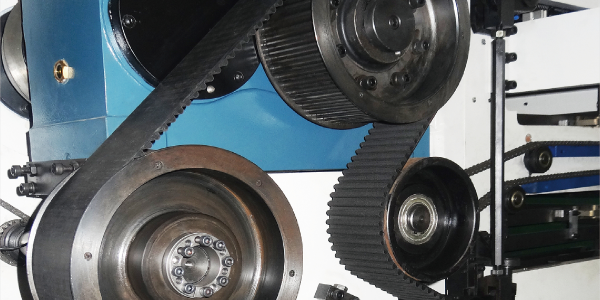

Timing belt drive, Intermittent mechanism |

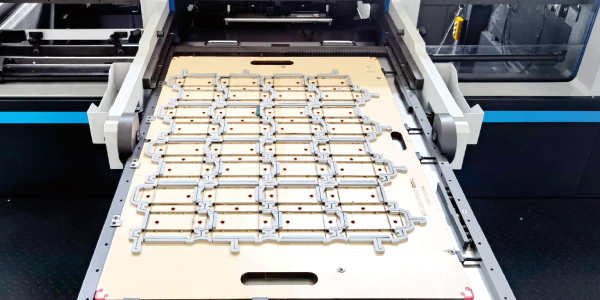

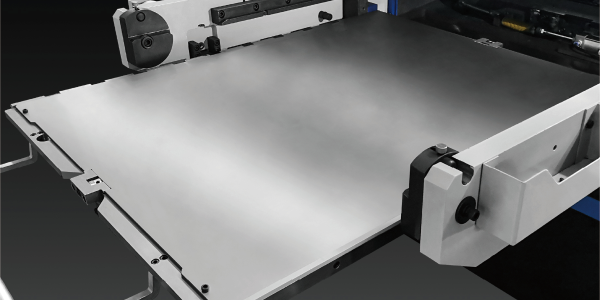

Plate frame |

Micro-adjustable die cutting plate |

|

|

|

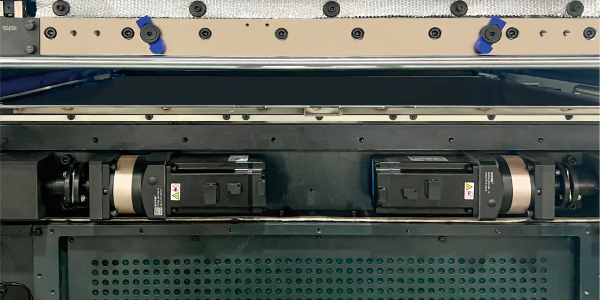

Servo controlled gripper bar positioning device |

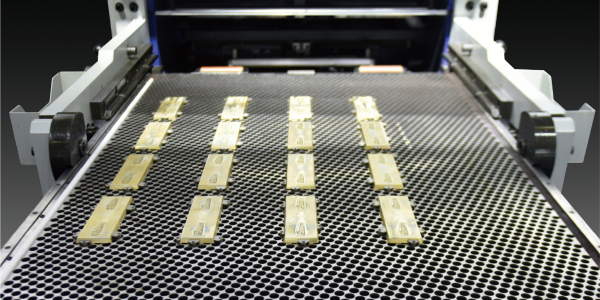

Honeycomb plate |

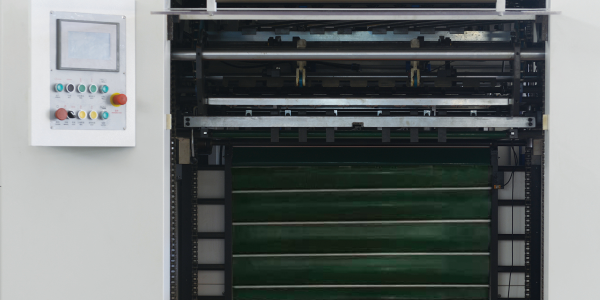

Non-stop roll-up curtain type paper delivery device |

|

|

|

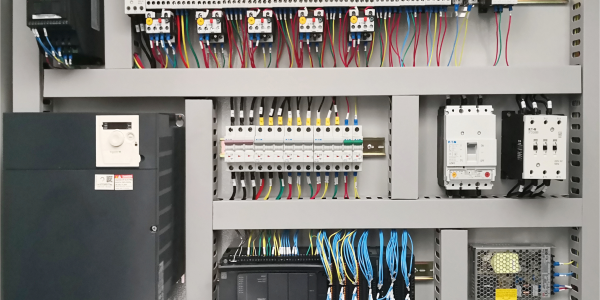

Electrical unit |

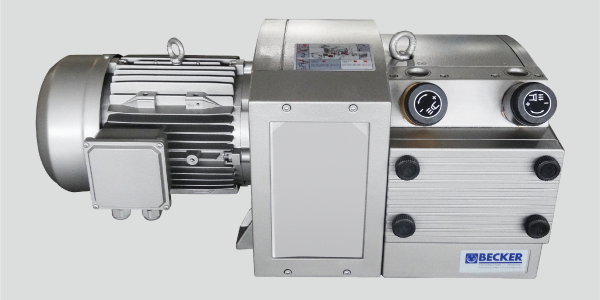

Germany vacuum pump |

Auto lubrication system |

|

||

Main unit cooling/lubrication mechanism |

Technical Paramete

|

Model |

MHK-820 |

MHK-1050 MHK-1050A MHK-1050AR |

MHK-1180 MHK-1180A MHK-1180AR |

|

Maximum Sheet Size |

820×600mm |

1050×750mm |

1180×1050mm |

|

Minimum Sheet Size |

310×260mm |

400×360mm |

400×360mm |

|

Maximum Cutting Size |

800×580mm |

1040×720mm |

1150×1000mm |

|

Maximum Embossing Area |

/ |

-- / -- / 1040×720mm |

-- / -- / 1150×1000mm |

|

Minimum Gripper Margin |

9-17mm |

9-17mm |

9-17mm |

|

Cutting Rule Height |

23.8mm |

23.8mm |

23.8mm |

|

Inner Chase Size |

910×610mm |

1123×760mm |

1230×1029mm |

|

Stock Range |

Cardboard: 80-2000g/m², 0.1-2mm Corrugated board: ≤4mm |

Cardboard: 80-2000g/m²,0.1-2mm |

Cardboard: 100-2000g/m², 0.1-2mm Corrugated board: ≤4mm |

|

Die Cutting Accuracy |

≤±0.1mm |

≤±0.075mm |

≤±0.1mm |

|

Embossing Accuracy |

/ |

-- / -- / ≤±0.075mm |

-- / -- / ≤±0.1mm |

|

Max.Cutting Force |

300T |

300T / 600T / 600T |

400T / 600T / 600T |

|

Max.Working Speed |

7500s/h |

7500s/h |

7000s/h |

|

|

1500mm |

1600mm |

1600mm |

|

Maximum Delivery Pile Height |

1300mm |

1400mm |

1400mm |

|

Electric-heated System |

/ |

-- / -- / 20 Heating zones,40-180℃ Adjustable |

-- / -- / 20 Heating zones,40-180℃ Adjustable |

|

Main Motor Power |

11KW |

11KW / 15KW / 15KW |

11KW / 15KW / 15KW |

|

Full Load Wattage |

16KW |

16KW / 21KW / 35KW |

18KW / 23KW / 35KW |

|

Air Requirement |

0.6-0.7MPa,≥0.37m³/min |

0.6-0.7MPa,≥0.37m³/min |

0.6-0.7MPa,≥0.37m³/min |

|

Net Weight of Machine |

12T |

16T / 18.5T / 18.5T |

20T / 21.5T / 22T |

|

Machine Dimensions(L×W×H) |

5695×3676×2185mm |

6150×4258×2334mm(1050) |

6262×4610×2504mm |

|

6150×4317×2334mm(1050A) |

|||

|

6150×4317×2334mm(1050AR) |