Advanced Control System Integration

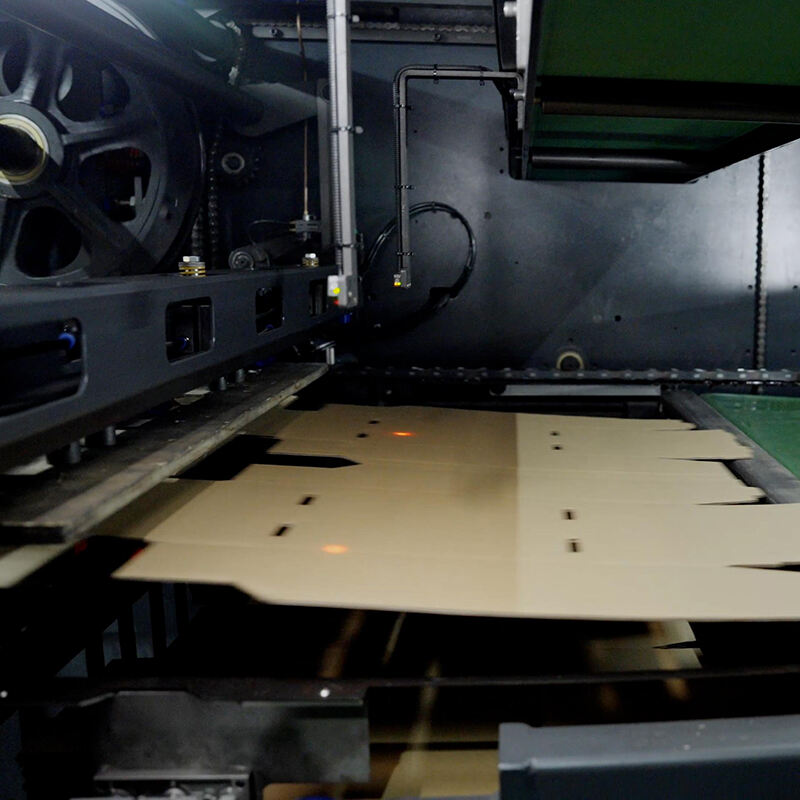

The sophisticated control system integration in modern flat bed die cutting machines represents a significant technological advancement in manufacturing precision. This system combines state of the art sensors, automated pressure adjustment mechanisms, and intuitive user interfaces to deliver unprecedented control over cutting operations. Operators can precisely adjust cutting parameters through digital controls, ensuring optimal performance across different materials and specifications. The system monitors critical variables such as cutting pressure, speed, and depth in real time, automatically making adjustments to maintain consistency. This level of control significantly reduces setup time and minimizes material waste while ensuring uniform quality across production runs. The integration of smart diagnostics helps prevent operational issues before they occur, maximizing uptime and productivity.