Cutting-Edge Technology Integration

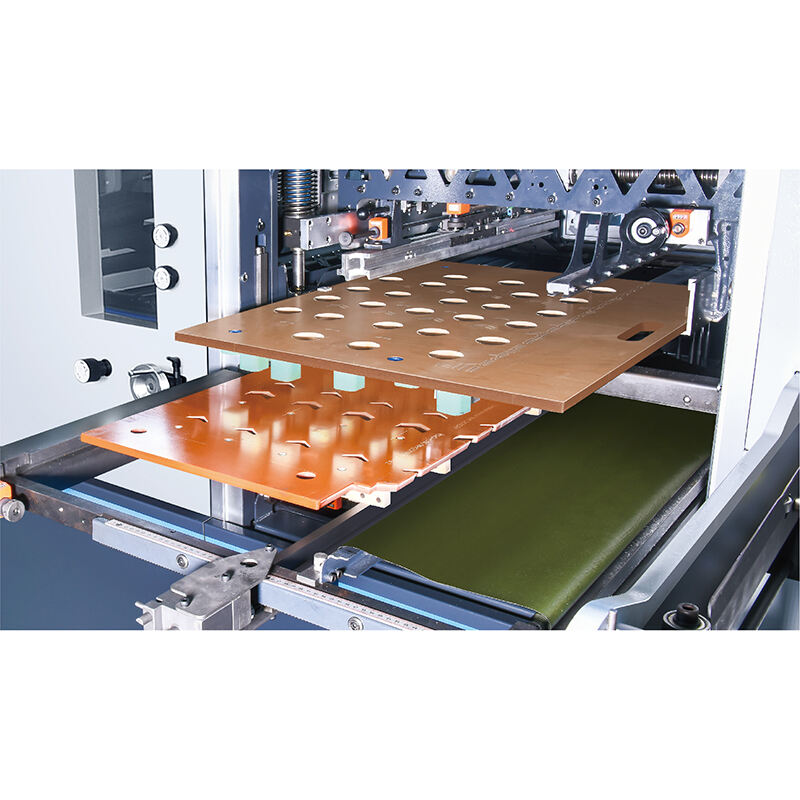

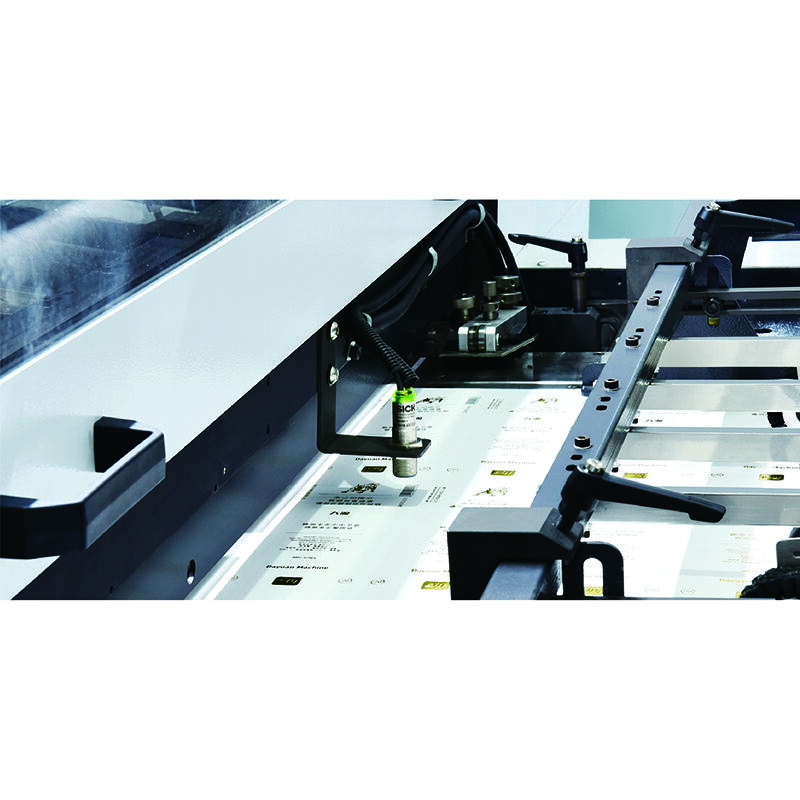

Modern die cutter manufacturers excel in incorporating state-of-the-art technology into their equipment. Their machines feature advanced computer numerical control (CNC) systems that enable precise, programmable operations with minimal human intervention. The integration of servo motor technology ensures smooth, accurate movements and positioning, resulting in consistently high-quality outputs. These manufacturers implement sophisticated optical registration systems that can detect and adjust for material variations in real-time, maintaining cutting accuracy even at high production speeds. The inclusion of automated material handling systems streamlines production processes while reducing the risk of material damage. Advanced software interfaces allow for easy program creation and modification, enabling quick changeovers between different cutting patterns and specifications.