Understanding Your Production Needs for a Creasing Machine

Assessing Production Volume and Throughput

Picking the correct creasing machine starts with knowing what kind of production volumes need handling. Most businesses should take stock of their weekly and monthly output numbers first before making any purchase decisions. A good match between machine capacity and actual production needs prevents headaches down the road. Throughput rate matters too the number of sheets a machine can process each hour directly affects how well it fits into existing workflows. When comparing options, check against industry standards for throughput performance across different models. Real world data from other manufacturers who've bought similar equipment often tells the story better than specs alone. Getting this right means avoiding underpowered machines that slow things down or overkill investments that sit idle most days.

Identifying Material Types and Thickness

When picking out a creasing machine, one important thing to consider is what kind of materials will actually be going through it. Think about all those different substrates we deal with daily cardstock, regular paper in all its weights from light to heavy, plus those tricky synthetic materials too. Getting clear on how thick these materials are matters a lot because not all machines handle everything equally well. Most folks find themselves checking what the manufacturers say about which materials work best with their equipment. Some industry pros even keep lists of compatible materials handy when shopping around. Matching up what the machine can do against what our materials need makes sense for anyone wanting smoother operations and better creases across all sorts of print jobs big or small.

Key Features to Evaluate in a Creasing Machine

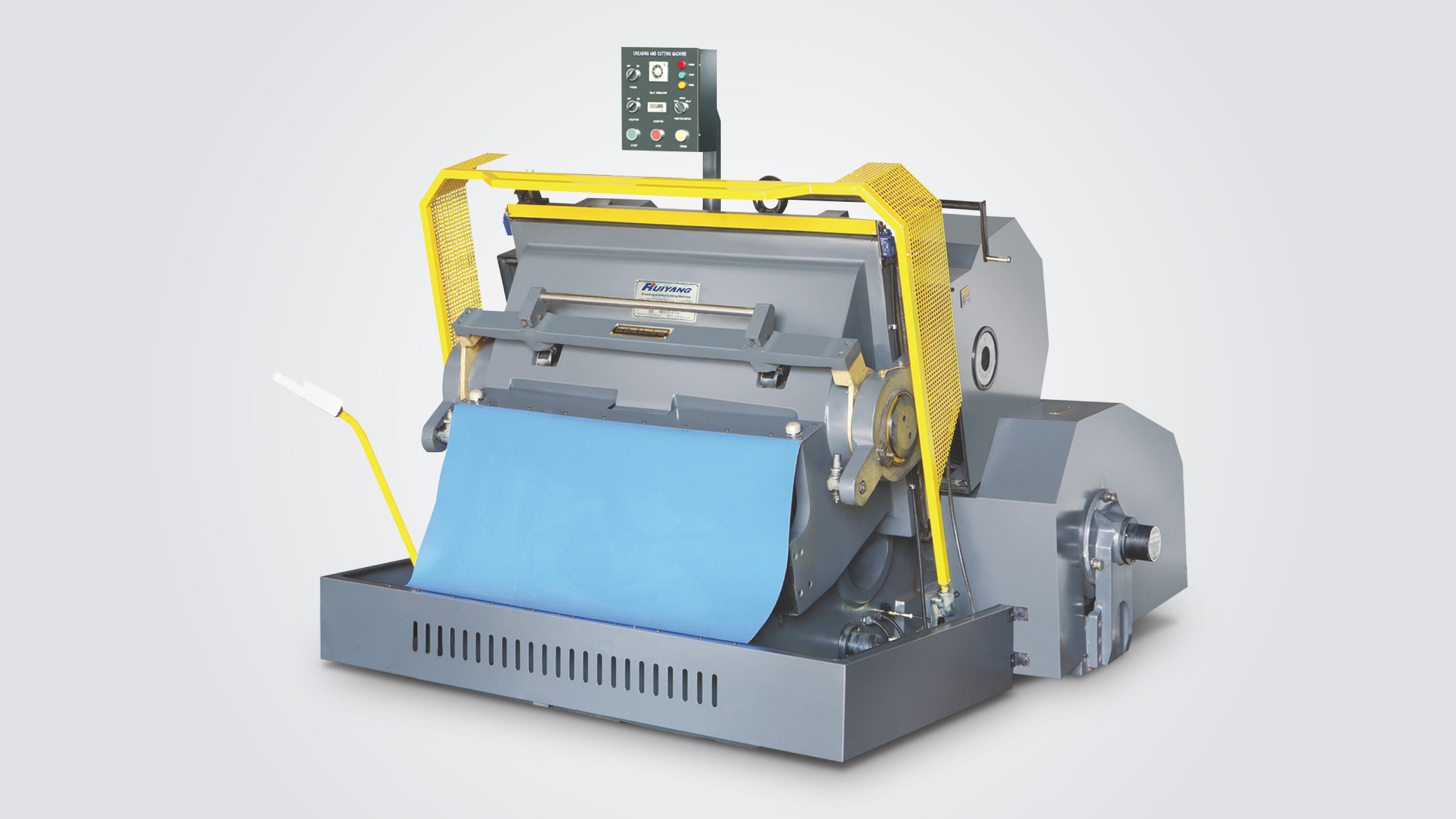

Automation Levels: Manual vs. Semi-Automatic vs. Fully Automatic

Picking out a creasing machine means getting familiar with different automation levels available in the market today, basically three main categories exist: manual, semi-auto, and full auto. The amount of hands-on work needed varies between them. With manual models, workers need to constantly operate everything themselves, something that often drives up staffing expenses and creates uneven results sometimes. Semi automatic versions cut down on this workload somewhat but still need operators to monitor things during runs, finding middle ground between spending money and getting good productivity. Fully automatic systems do wonders for cutting down on manpower requirements and boosting how much gets done per hour, although upfront investment costs tend to run pretty high plus maintenance bills add up over time too. Industry data shows these advanced machines boost shop floor efficiency quite a bit, yet many small scale operations find them hard to justify financially. So when making a decision about automation level, manufacturers should really look at what works best for their particular situation considering both financial constraints and actual production demands.

Adjustable Creasing Depth and Precision

Adjustable creasing depth makes all the difference when working with various materials. Machines need this feature to handle everything from lightweight paper right through to heavy duty cardstock, which really expands what they can do for different jobs. Getting precise creases matters too because it gives products that clean, finished look customers expect. Most manufacturer specs highlight why these adjustments matter so much. Take some models that come with micro adjustment settings, letting operators tweak pressure levels just enough to prevent tearing while still getting sharp folds. Better precision means higher quality work and less wasted material over time. Companies that invest in equipment with good adjustability and accuracy tend to see real improvements in their final products plus consistent results batch after batch.

Material Compatibility and Application-Specific Requirements

Handling Coated Papers and Digital Prints

Working with coated papers and digital prints brings its own set of headaches, mainly dealing with problems like warping and those annoying uneven creases. The glossy finish on coated papers makes them crack right along the fold lines, something that looks really bad when printed on darker colors. With digital prints there's another issue altogether because sometimes the toner just doesn't stick properly to the surface. Getting around these problems requires careful adjustment of the machines involved. Most seasoned printers will tell anyone who'll listen about getting the creasing depth and pressure spot on for nice clean folds without any damage. People in the business know from experience that good results come down to quality creasing work, which is why many shops invest in specialized equipment built specifically for handling both digital outputs and coated stock materials.

Addressing Challenges with Recycled or Specialty Materials

Working with recycled and specialty materials presents unique problems during the creasing process. Many of these materials have inconsistent fiber structures which makes them prone to breaking or folding unpredictably. To deal with this, operators need to tweak machine settings based on what kind of material they're dealing with. Some common fixes include lowering the creasing pressure and adjusting where exactly the creases are placed. Research indicates that changing temperature settings on the equipment can make a real difference when working with recycled content, cutting down on breakages by around 30% in some cases according to industry reports. That's why modern machinery needs to be flexible enough to handle all sorts of materials without compromising quality, something manufacturers increasingly demand as sustainability becomes more important in packaging production.

Cost Considerations and Long-Term ROI

Balancing Initial Investment with Maintenance Costs

Businesses thinking about buying a creasing machine usually look at how much they'll spend initially versus what kind of maintenance they'll face down the road. Sure, getting a top notch creasing machine comes with a hefty price tag upfront, but many find that the money saved on repairs and maintenance makes it worth every penny in the long run. Machines that work reliably tend to break down less often and don't need parts replaced so frequently, which means production keeps running smoothly without those costly interruptions. Looking at numbers helps too financial calculations show that while these durable machines cost more to buy, their day to day operating expenses end up being much lower. Over several years, this pattern tends to result in far better returns for companies willing to invest in quality from the start rather than cutting corners just to save a few dollars initially.

Evaluating Energy Efficiency and Operational Savings

How energy efficient a creasing machine is really matters for cutting down on running costs. Machines built with those special energy saving features cut back on carbon emissions sure, but they also mean smaller electric bills at month end, which adds up to real money saved year after year. Look at the labels on most modern equipment these days – things like ENERGY STAR ratings give manufacturers a good benchmark for comparing different models side by side. We've seen plenty of shops tell us stories about switching out old gear for newer energy efficient versions and watching their bottom line improve while ticking boxes on their sustainability reports too. The savings stack up fast enough that many companies find themselves getting their investment back faster than expected, especially when factoring in those tax incentives some governments offer for going green. For small to mid sized operations looking to trim expenses without sacrificing quality, this kind of upgrade makes both business sense and environmental sense.

Operational Best Practices for Optimal Performance

Calibration and Routine Maintenance Tips

Getting good results from creasing machines really depends on keeping them properly calibrated and doing regular maintenance work. When machines aren't calibrated right, we end up with problems like crooked creases or products that just don't look professional. Most shops find that sticking to a basic maintenance schedule makes all the difference. Start by giving every part a thorough cleaning to stop dirt from building up over time. Check those blades and rollers for signs of wear since worn out parts will definitely affect quality. Also make sure everything is lined up exactly how the manufacturer recommends in their manuals. Companies like Technifold actually put together detailed guides for this kind of stuff, which helps operators know what to look for during inspections. Following through with these simple steps means fewer breakdowns and better output across the board for any business running creasing operations.

Training Staff for Safe and Efficient Machine Use

When talking about creasing machines, nobody really disputes how important good staff training is for keeping operations both safe and productive. Proper training makes sure workers know exactly how these machines should be handled, preventing accidents while also protecting expensive equipment from being damaged through improper use. Well-trained personnel actually make a big difference in how machines perform day to day, cutting down on unexpected breakdowns and keeping production moving smoothly. Industry data shows something pretty clear too: companies that spend time and resources on ongoing training tend to boost their output numbers while seeing fewer incidents on the shop floor. For most manufacturers, this isn't just about compliance anymore. It's become standard practice because smart operators simply get better results over time.

FAQs

What should I consider when assessing production volume for a creasing machine?

You should evaluate your business’s weekly and monthly output demands and consider the machine’s throughput rate to ensure it aligns with your production targets.

What materials can creasing machines handle?

Creasing machines can handle various substrates such as cardstock, different paper weights, and synthetic materials. It’s important to check machine specifications for compatibility.

How do automation levels affect creasing machine selection?

Automation levels dictate the degree of human intervention needed. Manual machines require more labor, while fully automatic machines maximize output with minimal labor, though they cost more.

Why is adjustable creasing depth important?

Adjustable creasing depth allows machines to handle different material thicknesses, ensuring versatility and quality output across various projects.

How do I maintain optimal creasing machine performance?

Regular calibration and routine maintenance, including cleaning and checking parts for wear, are essential practices to maintain precision and minimize downtime.