Precision and Consistency in Paper Folding

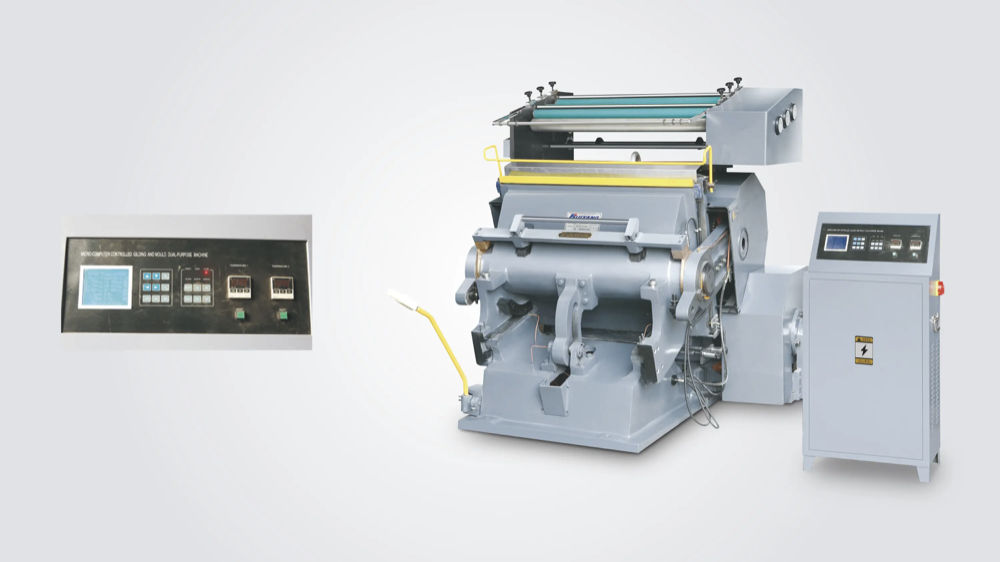

Getting those sharp, clean creases matters a lot when making professional grade paper and cardboard items. It takes proper methods plus good equipment like quality creasing machines to pull this off. These machines really help make sure paper folds come out neat and accurate every time. Research shows automated systems create folds about 50% more consistently compared to doing things by hand, which makes all the difference in how brochures look, how packaging stands up, and basically anything else that gets printed. Digital measurement tools built into modern machines keep track of crease depth so everything stays uniform across batches, giving products that finished look customers expect. When manufacturers bring this kind of tech into their workflow, they don't just get better looking results they actually hit those industry standards for accuracy that clients demand.

Reducing Human Error in Repetitive Tasks

Creasing machines that automate the process really cut down on mistakes when it comes to folding paper repeatedly. When people do this manually, there's always some variation between folds, and that inconsistency shows up in the finished product. The good news is that automated systems perform each fold exactly the same way every time, so those pesky human errors just disappear. Some recent manufacturing reports indicate that bringing tech into the mix for routine tasks can slash error rates as much as 90 percent. What's interesting too is how workers adapt to working alongside these machines. Proper training makes all the difference, boosting both accuracy and speed while getting more done overall. Companies that switch to automation typically find their workflows become smoother and they maintain better quality control across their production runs.

Adaptability to Various Paper Weights and Materials

What makes creasing machines so popular is how well they work with all sorts of paper thicknesses and materials, which gives them real flexibility for different jobs around the shop. They tackle everything from thin brochure stock right up to thick cardboard boxes used in packaging, making these machines pretty versatile additions to any workshop. The secret lies in those adjustable tools that let operators tweak settings depending on what kind of material they're working with. For small print shops or packaging facilities, this means handling multiple projects without having to invest in separate equipment for each task. Space savings alone can be significant when compared to buying several dedicated machines. Plus, manufacturers benefit from smoother workflows since one machine handles so many requirements. That's why most print houses keep at least one creasing machine handy these days it just makes sense for operations that need to stay competitive while keeping costs under control.

Enhancing Structural Integrity of Cardboard Products

Preventing Fiber Damage During Folding

Creasing machines are really important when it comes to keeping fibers safe while folding cardboard products, something that directly affects how strong those boxes stay. Studies show that when we get the creasing right, fiber breakage drops around 40 percent compared to old school manual folding where fibers tend to get damaged and boxes become weaker. Getting the hang of just the right angle and pressure matters a lot too because this determines whether the cardboard keeps its strength over time. For businesses investing in these modern machines, they see better packaging quality overall. Products actually survive shipping and handling much better, which makes everyone from warehouse workers to customers happier with the end result.

Improving Durability for Packaging Applications

When done right, creasing makes cardboard way tougher, which is why it works so well for packaging stuff that needs protection during shipping. Stronger boxes mean less broken products when they reach customers, and nobody wants to open a package full of damaged goods. Companies using machines for creasing see around 25 percent fewer problems with their packaging failing, according to some industry stats we've seen floating around lately. That kind of improvement cuts down on wasted materials while showing customers that the company cares about what happens after delivery. People tend to remember brands that consistently send out undamaged packages, and word spreads fast these days through online reviews and social media chatter.

Optimizing Design for Load-Bearing Performance

When designers combine proper folding methods with structural considerations, cardboard boxes can actually hold much more weight than they look like. The right fold patterns spread out pressure points across the surface, something really important when shipping heavy goods through warehouses or delivery trucks. Packaging engineers often point to certain crease designs that boost box strength without wasting extra cardboard. These smart folds save money on materials while still keeping things sturdy enough for long journeys. Boxes made this way stay intact even after rough handling, so companies don't have to add those bulky plastic inserts or extra layers just to protect fragile contents during transport.

Streamlining Production Efficiency

Accelerating High-Volume Output

Creasing machines that are automated really speed things up when it comes to producing large quantities, which is pretty much essential these days given how markets keep expanding. When companies switch from doing everything manually to going fully automatic, they often see their production numbers jump around three times what they were before according to what most industry folks report. The reason behind this massive efficiency gain? Setup takes minutes instead of hours, and once programmed, these machines handle different jobs without needing constant reconfiguration. For manufacturers dealing with unpredictable customer orders or seasonal spikes, this kind of flexibility makes all the difference. It means staying ahead of competitors who might still be struggling with outdated methods while keeping costs under control during those hectic periods when demand suddenly surges.

Minimizing Material Waste Through Precision

Getting the creases right makes a big difference in product quality and cuts down on wasted materials, which means the whole process becomes greener and cheaper too. Factories that switch to automated creasing machines report cutting their scrap rates around 20% or so, something that adds up nicely in their annual budgets. When manufacturers invest in those precise machines for folding and shaping, they're actually doing two things at once saving resources and hitting those environmental targets set by many governments these days. Plus, it helps the business side of things because nobody wants to throw away good money on wasted raw materials. Most packaging plants have found this approach works best when combined with regular maintenance checks on equipment to keep everything running smoothly without unnecessary energy consumption.

Integrating with Automated Workflow Systems

When creasing machines get hooked up to automated workflow systems, the whole production process becomes much smoother and runs faster than before. These connected systems let operators see problems as they happen and make changes on the fly, which keeps everything running at peak levels. Some actual factory tests have shown that when manufacturers implement this kind of integration, their operations speed up by around 30%. The big picture is that having all these parts work together creates one solid production chain. Companies find they produce more goods without sacrificing quality, meet deadlines consistently, and customers tend to come back because they know what they're getting will be delivered right on time and in good condition.

Reducing Energy Consumption Compared to Manual Processes

Moving away from manual to automated creasing equipment often leads to significant drops in energy usage across manufacturing facilities. Industry data suggests many businesses see around 35-40% reductions in their electricity bills once they switch to these automated systems. The machines themselves are built with energy conservation in mind, so they save money at the same time as helping factories meet environmental targets through reduced emissions. For manufacturers looking to green their operations without breaking the bank, automation offers a win-win situation where both bottom lines and ecological concerns get addressed together.

Supporting Recyclable Material Compatibility

Creasing machines that automate processes work pretty well with materials we can recycle again and again, which supports greener manufacturing methods across industries. These days, companies need to use stuff that breaks down easily when tossed because customers want sustainable options more than ever before. Getting certified证明 that equipment works properly with recyclable content isn't just good practice it actually makes brands look better in the eyes of shoppers who care about planet friendly products. We've seen some manufacturers gain real traction after showing their commitment to recycling standards, opening doors to new markets filled with people looking for responsible alternatives in packaging solutions.

Long-Term Savings on Labor and Material Costs

Putting money into better creasing tech actually pays off big time when looking at labor and material expenses over time. Some businesses saw their costs drop by around 20 percent within five years after switching systems, mainly because they needed fewer workers doing repetitive tasks and wasted less material during production runs. The trend toward automation shows no signs of slowing down either, so those kinds of savings should keep growing as machines take over more of the manual work. For manufacturers trying to stay ahead in today's market, getting comfortable with these new technologies isn't just about saving money it's about staying relevant while competitors who resist change fall behind.

Compliance with Packaging Safety Regulations

For companies dealing with packaging regulations, automated creasing machines have become almost indispensable these days. They create those precise folds consistently across all products, something that matters a lot when it comes to keeping packages intact during shipping and handling. This kind of consistency helps meet those tough safety requirements set by regulatory bodies. Getting this right opens doors to bigger markets too many distributors won't work with brands that don't follow proper protocols. And let's face it, getting hit with fines or losing shelf space because of non-compliance would hurt anyone's bottom line. Plus, most modern systems come with built-in tracking features that generate records automatically. These documents not only prove compliance but also build trust with customers and investors who want assurance that their products are handled safely throughout the supply chain.

Enhancing Brand Perception Through Flawless Finishes

Getting those perfect folds and creases right on packaging makes all the difference when it comes to how people see a brand and whether they'll trust what's inside. Research shows folks tend to grab products with better looking packages about 70% more often than ones that look sloppy. When something looks put together properly on store shelves, customers start thinking the company cares about details. That kind of attention builds loyalty over time because people want to support businesses that seem serious about quality work. Good packaging isn't just pretty paper work either it actually works hard behind the scenes to boost sales while making shoppers feel confident their money was well spent.

Enabling Customization for Premium Product Lines

Creasing tech makes it possible to customize packaging, which helps support premium product ranges and creative marketing approaches. When companies put thought into their package design, they highlight what makes their products special. This works really well for smaller markets where customers want something different from the usual stuff on shelves. Brands that offer these personalized touches tend to see better connections with their customers too. The market these days is all about standing out, so when companies provide custom packaging options, they set themselves apart from others in the same space. Many consumers are starting to look for those unique, high quality items that aren't mass produced, making this trend increasingly important for businesses wanting to grow their customer base.

FAQ Section

What are the primary benefits of using creasing machines?

Creasing machines ensure precision and consistency in paper folding, reducing human error, enhancing durability, and adapting to various materials. They also streamline production efficiency and support eco-friendly practices.

How do creasing machines improve the structural integrity of cardboard packaging?

These machines prevent fiber damage during folding, improving load distribution and durability, which is crucial for maintaining the strength of cardboard packaging during transit and handling.

Can creasing machines work with recyclable materials?

Yes, creasing machines are designed to be compatible with recyclable materials, supporting sustainable manufacturing practices and aiding in achieving eco-friendly certification.

How do automated creasing machines contribute to cost savings?

These machines reduce labor and material costs over time by minimizing errors and waste and optimize energy consumption, resulting in significant long-term savings.

Table of Contents

- Precision and Consistency in Paper Folding

- Reducing Human Error in Repetitive Tasks

- Adaptability to Various Paper Weights and Materials

- Enhancing Structural Integrity of Cardboard Products

- Streamlining Production Efficiency

- Reducing Energy Consumption Compared to Manual Processes

- Supporting Recyclable Material Compatibility

- Long-Term Savings on Labor and Material Costs

- FAQ Section