যথাযথ সরঞ্জাম যত্নের মাধ্যমে শিল্প দক্ষতা সর্বাধিককরণ

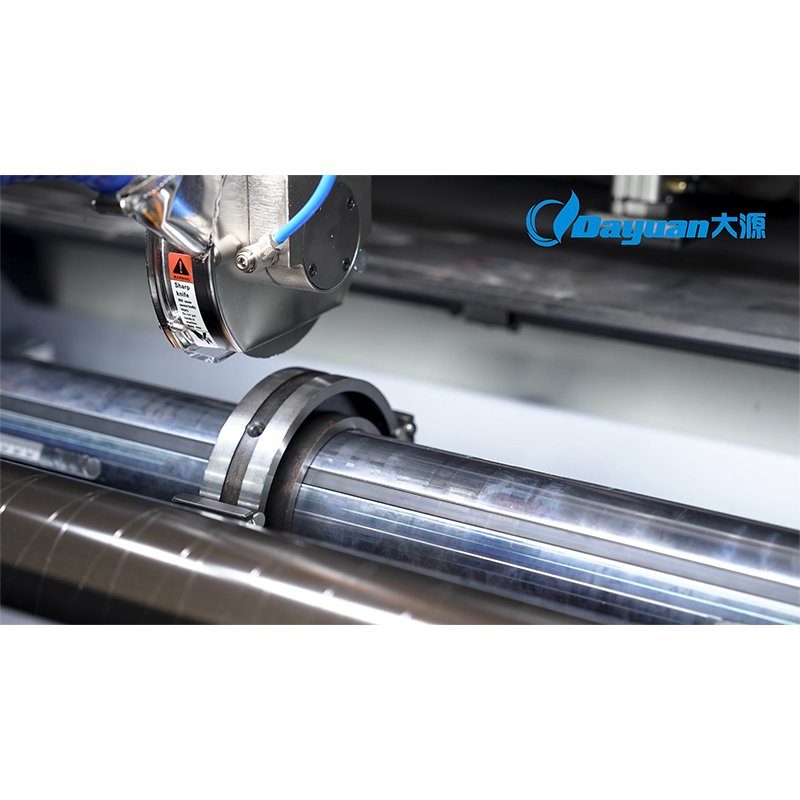

অনেক উৎপাদন কার্যক্রমের মূল ভিত্তি হল তাদের কাটার যন্ত্র ব্যবস্থাগুলির নির্ভরযোগ্য কর্মক্ষমতা। বৃহত উপাদানের রোলগুলিকে ছোট, আরও সহজে পরিচালনাযোগ্য প্রস্থে রূপান্তর করার জন্য এই নির্ভুল যন্ত্রগুলি অপরিহার্য, যা কাগজ প্রক্রিয়াকরণ থেকে শুরু করে ধাতু তৈরি পর্যন্ত শিল্পগুলিকে পরিবেশন করে। সঠিক রক্ষণাবেক্ষণ কৌশল বোঝা না শুধুমাত্র সরঞ্জামের আয়ু বাড়ায় না, কিন্তু ধ্রুবক পণ্যের গুণমান নিশ্চিত করে এবং ব্যয়বহুল সময় হ্রাস করে।

আধুনিক স্লিটিং মেশিন প্রযুক্তি উল্লেখযোগ্যভাবে বিকশিত হয়েছে, যেখানে উন্নত বৈশিষ্ট্যগুলি অন্তর্ভুক্ত করা হয়েছে যা একটি ব্যাপক রক্ষণাবেক্ষণ পদ্ধতির দাবি করে। আপনি যদি একটি ঐতিহ্যবাহী যান্ত্রিক স্লিটার বা একটি আধুনিক স্বয়ংক্রিয় সিস্টেম চালাচ্ছেন কিনা না কেন, চূড়ান্ত কর্মদক্ষতার জন্য সঠিক রক্ষণাবেক্ষণ অনুশীলন বাস্তবায়ন করা অত্যন্ত গুরুত্বপূর্ণ।

মূল উপাদান এবং রক্ষণাবেক্ষণের অগ্রাধিকার

ব্লেড সিস্টেমের রক্ষণাবেক্ষণ

কাটিং মেকানিজমটি যেকোনো স্লিটিং মেশিনের হৃদয় প্রতিনিধিত্ব করে, যার জন্য বিস্তারিত বিষয়গুলির প্রতি যত্নশীল হওয়া প্রয়োজন। পরিষ্কার এবং নির্ভুল কাটিং অর্জনের জন্য নিয়মিত ব্লেড পরীক্ষা এবং রক্ষণাবেক্ষণ অপরিহার্য। অপারেটরদের দৈনিকভাবে ব্লেডের ধার পরীক্ষা করা উচিত এবং ক্ষয়, চিপ বা অসম প্রান্তের লক্ষণগুলি খুঁজে বার করা উচিত যা কাটিং গুণমানকে ক্ষতিগ্রস্ত করতে পারে।

ব্যবহারের ধরন এবং প্রক্রিয়াকৃত উপকরণের প্রকারের উপর ভিত্তি করে পেশাদার ব্লেড ধার ধরানোর সময়সূচী নির্ধারণ করা উচিত। সর্বোত্তম কর্মক্ষমতা অর্জনের জন্য ব্লেড রক্ষণাবেক্ষণের ইতিহাস এবং প্রতিস্থাপন চক্রের বিস্তারিত রেকর্ড রাখা উচিত। এই তথ্য অপ্রত্যাশিত ব্যর্থতা প্রতিরোধে সহায়তা করে এমন ভবিষ্যদ্বাণীমূলক রক্ষণাবেক্ষণ সময়সূচী প্রতিষ্ঠার জন্য সাহায্য করে।

ড্রাইভ সিস্টেম যত্ন

ড্রাইভ সিস্টেমটি স্লিটিং মেশিনের মাধ্যমে আংশিক এবং সামঞ্জস্যপূর্ণ উপকরণ ফিডিং নিশ্চিত করে। মোটর, বিয়ারিং এবং ড্রাইভ বেল্টগুলির নিয়মিত পরীক্ষা করে প্রধান সমস্যায় পরিণত হওয়ার আগেই সম্ভাব্য সমস্যাগুলি চিহ্নিত করা যায়। অস্বাভাবিক শব্দ শুনুন, বেল্টের টানটি ঠিক আছে কিনা তা পরীক্ষা করুন এবং চলাকালীন বিয়ারিংয়ের তাপমাত্রা নজরদারি করুন।

লুব্রিকেশন ড্রাইভ সিস্টেমের দীর্ঘায়ুতে একটি গুরুত্বপূর্ণ ভূমিকা পালন করে। উৎপাদকের সুপারিশ এবং পরিচালন অবস্থার উপর ভিত্তি করে একটি সিস্টেম্যাটিক লুব্রিকেশন সূচি প্রতিষ্ঠা করুন। শুধুমাত্র নির্দিষ্ট লুব্রিকেন্ট ব্যবহার করুন এবং ভবিষ্যতের তথ্যের জন্য সমস্ত রক্ষণাবেক্ষণ ক্রিয়াকলাপ নথিভুক্ত করুন।

উন্নত রক্ষণাবেক্ষণ কৌশল

প্রতিরক্ষামূলক রক্ষণাবেক্ষণ স্কেজুল

ছেদন মেশিনের নির্ভরযোগ্যতার জন্য একটি ব্যাপক প্রতিরোধমূলক রক্ষণাবেক্ষণ প্রোগ্রাম বাস্তবায়ন করা অপরিহার্য। এর মধ্যে নিয়মিত পরিষ্কারের সূচি, উপাদান পরিদর্শন এবং ক্ষয়ক্ষতিগ্রস্ত অংশগুলির সিস্টেম্যাটিক প্রতিস্থাপন অন্তর্ভুক্ত রয়েছে। দৈনিক, সাপ্তাহিক এবং মাসিক রক্ষণাবেক্ষণ কাজের জন্য বিস্তারিত চেকলিস্ট তৈরি করুন যাতে কোনো গুরুত্বপূর্ণ দিক উপেক্ষা না করা হয়।

ডিজিটাল রক্ষণাবেক্ষণ ব্যবস্থাপনা সিস্টেমগুলি সূচি ট্র্যাক করতে, কাজের আদেশ তৈরি করতে এবং বিস্তারিত সেবা রেকর্ড রাখতে সাহায্য করতে পারে। এই সরঞ্জামগুলি সরঞ্জামের কর্মক্ষমতা প্রবণতা সম্পর্কে মূল্যবান অন্তর্দৃষ্টি প্রদান করে এবং রক্ষণাবেক্ষণের সময়সীমা অনুকূলিত করতে সাহায্য করে।

ক্যালিব্রেশন এবং সংস্থাপন পদ্ধতি

নির্ভুল ক্যালিব্রেশন সঠিক কাটার প্রস্থ এবং ন্যূনতম উপকরণ অপচয় নিশ্চিত করে। স্লিটিং মেশিনের সাজানোর পরামিতির নিয়মিত পরীক্ষা ও সমন্বয় আদর্শ কর্মক্ষমতা বজায় রাখে। এর মধ্যে সেন্সরের অবস্থান যাচাই করা, গাইড রোলারগুলি পরীক্ষা করা এবং উপযুক্ত টেনশন নিয়ন্ত্রণ সেটিংস নিশ্চিত করা অন্তর্ভুক্ত রয়েছে।

ক্যালিব্রেশন পদ্ধতি এবং ফলাফলের ডকুমেন্টেশন বিভিন্ন অপারেটর এবং শিফটের মধ্যে সামঞ্জস্য বজায় রাখতে সাহায্য করে। আরও নির্ভুল এবং দক্ষ ক্যালিব্রেশন প্রক্রিয়ার জন্য ডিজিটাল পরিমাপ যন্ত্র বাস্তবায়ন বিবেচনা করুন।

পরিবেশগত বিবেচনা এবং নিরাপত্তা প্রোটোকল

কর্মস্থল ব্যবস্থাপনা

আপনার স্লিটিং মেশিনের চারপাশের পরিবেশ এর কর্মক্ষমতা এবং রক্ষণাবেক্ষণের প্রয়োজনীয়তার উপর উল্লেখযোগ্য প্রভাব ফেলে। পরিষ্কার, ধুলিমুক্ত অবস্থা বজায় রাখুন এবং সুপারিশকৃত পরিসরের মধ্যে তাপমাত্রা ও আর্দ্রতা নিয়ন্ত্রণ করুন। উপযুক্ত ভেন্টিলেশন ওভারহিটিং প্রতিরোধ করে এবং মেশিনের কার্যকারিতা প্রভাবিত করতে পারে এমন ধ্বংসাবশেষের সঞ্চয় কমায়।

রক্ষণাবেক্ষণ পদ্ধতির সময় দ্রুত অ্যাক্সেসের জন্য সিস্টেম্যাটিকভাবে সরঞ্জাম এবং স্পেয়ার পার্টস সাজান। এই সংগঠন ডাউনটাইম কমায় এবং নিশ্চিত করে যে রক্ষণাবেক্ষণের কাজ কার্যকরভাবে এবং নিরাপদে সম্পন্ন হচ্ছে।

নিরাপত্তা ব্যবস্থা এবং প্রশিক্ষণ

বিস্তৃত নিরাপত্তা প্রোটোকলগুলি অপারেটর এবং সরঞ্জাম উভয়কেই সুরক্ষা দেয়। লকআউট/ট্যাগআউট পদ্ধতি এবং ব্যক্তিগত সুরক্ষা সরঞ্জামের প্রয়োজনীয়তা সহ রক্ষণাবেক্ষণ ক্রিয়াকলাপের জন্য বিস্তারিত নিরাপত্তা পদ্ধতি তৈরি করুন। নিয়মিত প্রশিক্ষণ সেশনগুলি কর্মীদের সঠিক রক্ষণাবেক্ষণ কৌশল এবং নিরাপত্তা অনুশীলন সম্পর্কে আপডেট রাখে।

নিয়ন্ত্রক প্রয়োজনীয়তা মেনে চলা নিশ্চিত করতে সমস্ত নিরাপত্তা পদ্ধতি নথিভুক্ত করুন এবং প্রশিক্ষণের রেকর্ড রাখুন। রক্ষণাবেক্ষণ কর্মীদের জন্য একটি নিরাপত্তা সার্টিফিকেশন প্রোগ্রাম বাস্তবায়নের কথা বিবেচনা করুন।

সমস্যা সমাধান এবং পারফরম্যান্স অপ্টিমাইজেশন

সাধারণ সমস্যা এবং সমাধান

সাধারণ সমস্যাগুলি বোঝা রক্ষণাবেক্ষণ দলগুলিকে দ্রুত এবং কার্যকরভাবে প্রতিক্রিয়া জানাতে সহায়তা করে। অসম কাটিং, উপকরণ ট্র্যাকিং সমস্যা এবং অসঙ্গতিপূর্ণ টেনশন নিয়ন্ত্রণ হল সাধারণ সমস্যাগুলির মধ্যে। সমস্যা সমাধানের জন্য এমন গাইড তৈরি করুন যা মূল কারণগুলি চিহ্নিত করতে এবং ধাপে ধাপে সমাধানের পদ্ধতি প্রদান করতে সাহায্য করে।

উদ্ভূত সমস্যা এবং প্রয়োগ করা সমাধানগুলির বিস্তারিত রেকর্ড রাখুন। নতুন রক্ষণাবেক্ষণ কর্মীদের প্রশিক্ষণ এবং সামগ্রিক যন্ত্রপাতির নির্ভরযোগ্যতা উন্নত করার জন্য এই জ্ঞানভাণ্ডার অমূল্য সম্পদে পরিণত হয়।

পারফরম্যান্স নিরীক্ষণ

প্রধান কর্মক্ষমতা সূচকগুলির নিয়মিত নজরদারি উৎপাদনে প্রভাব ফেলার আগেই সম্ভাব্য সমস্যাগুলি চিহ্নিত করতে সাহায্য করে। কাটিংয়ের নির্ভুলতা, উৎপাদনের গতি এবং ডাউনটাইম প্যাটার্নের মতো মেট্রিকগুলি ট্র্যাক করুন। আধুনিক স্লিটিং মেশিন সিস্টেমগুলিতে প্রায়শই অন্তর্নির্মিত মনিটরিং সুবিধা থাকে যা কারখানার সমগ্র ডেটা সংগ্রহ ব্যবস্থার সাথে একীভূত করা যেতে পারে।

রক্ষণাবেক্ষণের সময়সূচী অনুকূলিত করতে এবং কর্মক্ষমতা উন্নতির সুযোগগুলি চিহ্নিত করতে সংগৃহীত তথ্য ব্যবহার করুন। এই মেট্রিকগুলির নিয়মিত বিশ্লেষণ রক্ষণাবেক্ষণে বিনিয়োগের ঔচিত্য প্রমাণ করতে এবং উৎপাদনশীলতার উপর তাদের প্রভাব দেখাতে সাহায্য করে।

প্রায়শই জিজ্ঞাসিত প্রশ্নাবলী

স্লিটিং মেশিনের ব্লেডগুলি কত ঘন ঘন প্রতিস্থাপন করা উচিত?

ব্লেড প্রতিস্থাপনের ঘনত্ব উপকরণের ধরন, উৎপাদন পরিমাণ এবং কাটার বিবরণের মতো বিভিন্ন কারণের উপর নির্ভর করে। সাধারণভাবে, শিল্প ছেদন মেশিনগুলি স্বাভাবিক অপারেশনের অধীনে প্রতি 3-6 মাস অন্তর ব্লেড প্রতিস্থাপনের প্রয়োজন হয়। তবে, কাটার গুণমানের দৈনিক পরিদর্শন এবং নজরদারি আপনার নির্দিষ্ট প্রয়োগের জন্য সর্বোত্তম প্রতিস্থাপন সময়সূচী নির্ধারণে সাহায্য করে।

ছেদন মেশিনের অনুপযুক্ত রক্ষণাবেক্ষণের লক্ষণগুলি কী কী?

প্রধান নির্দেশকগুলির মধ্যে রয়েছে অসম বা ছিঁড়ে যাওয়া কাট, অপারেশনের সময় অতিরিক্ত শব্দ, উপকরণ ট্র্যাকিং সমস্যা এবং বিদ্যুৎ খরচ বৃদ্ধি। নিয়মিত কম্পন বিশ্লেষণ এবং কর্মক্ষমতা নজরদারি গুরুতর সমস্যা দেখা দেওয়ার আগেই রক্ষণাবেক্ষণের প্রয়োজনীয়তা চিহ্নিত করতে সাহায্য করে।

আমার স্লিটিং মেশিনের আয়ু বাড়ানোর উপায় কী?

একটি ব্যাপক অগ্রদত্ত রক্ষণাবেক্ষণ পরিকল্পনা চালু করুন, অপারেটর প্রশিক্ষণ নিশ্চিত করুন, পরিষ্কার পরিবেশে কাজ করুন এবং লুব্রিকেশন ও সমন্বয়ের জন্য প্রস্তুতকারকের নির্দেশাবলী অনুসরণ করুন। ঘর্ষণজনিত অংশগুলির নিয়মিত পরীক্ষা এবং সময়মতো প্রতিস্থাপন যন্ত্রপাতির আয়ু উল্লেখযোগ্যভাবে বাড়ায় এবং সর্বোত্তম কর্মক্ষমতা বজায় রাখে।