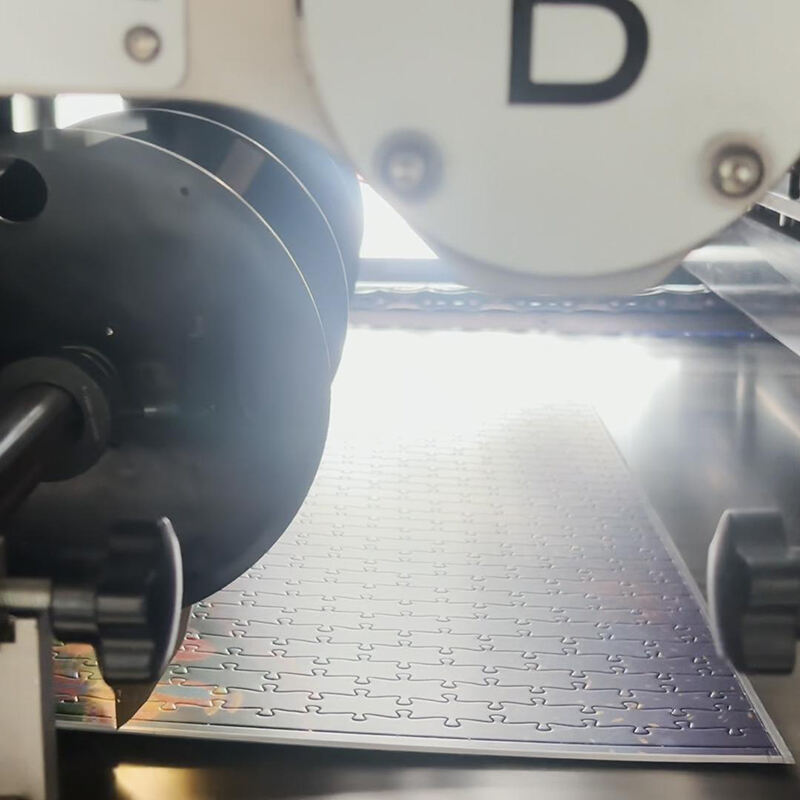

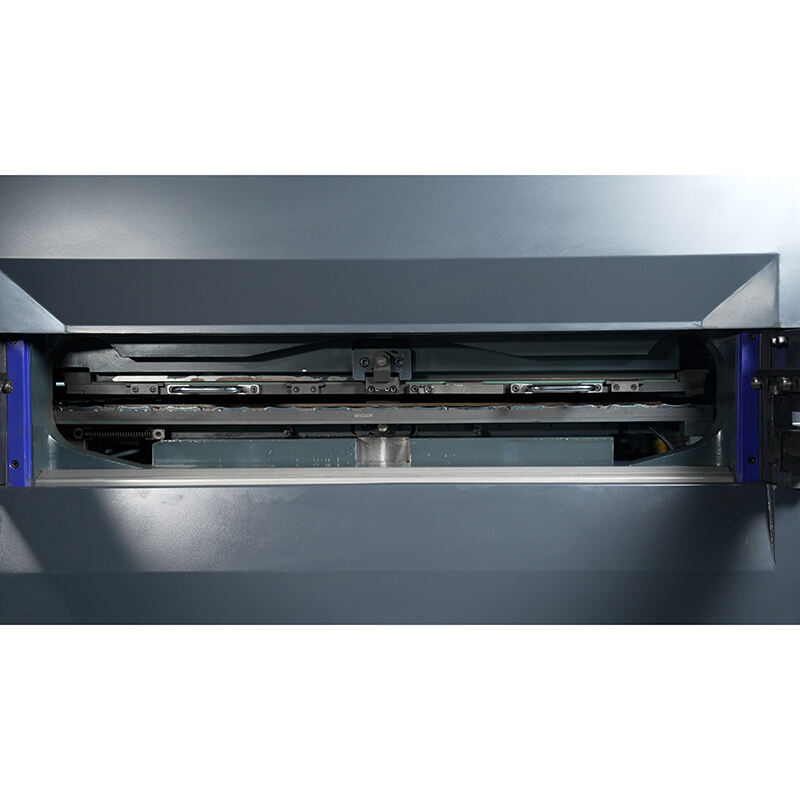

Advanced Digital Control System

The jigsaw puzzle maker machines advanced digital control system represents a breakthrough in puzzle manufacturing technology. This sophisticated system integrates touch-screen interfaces with intuitive controls, allowing operators to easily program and adjust cutting parameters. The system stores multiple cutting patterns and designs, enabling quick transitions between different puzzle styles. Real-time monitoring capabilities provide instant feedback on production status, material usage, and machine performance. The digital control system also includes automated error detection and correction features, minimizing production defects and ensuring consistent quality. Integration capabilities with design software allow for seamless transfer of new puzzle patterns and artwork, streamlining the production process.