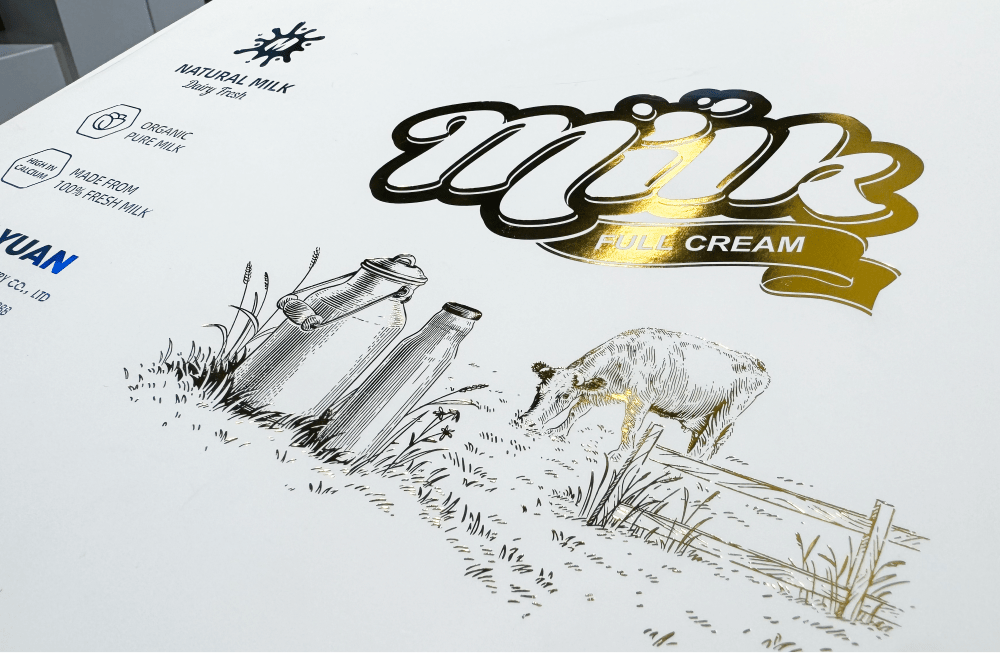

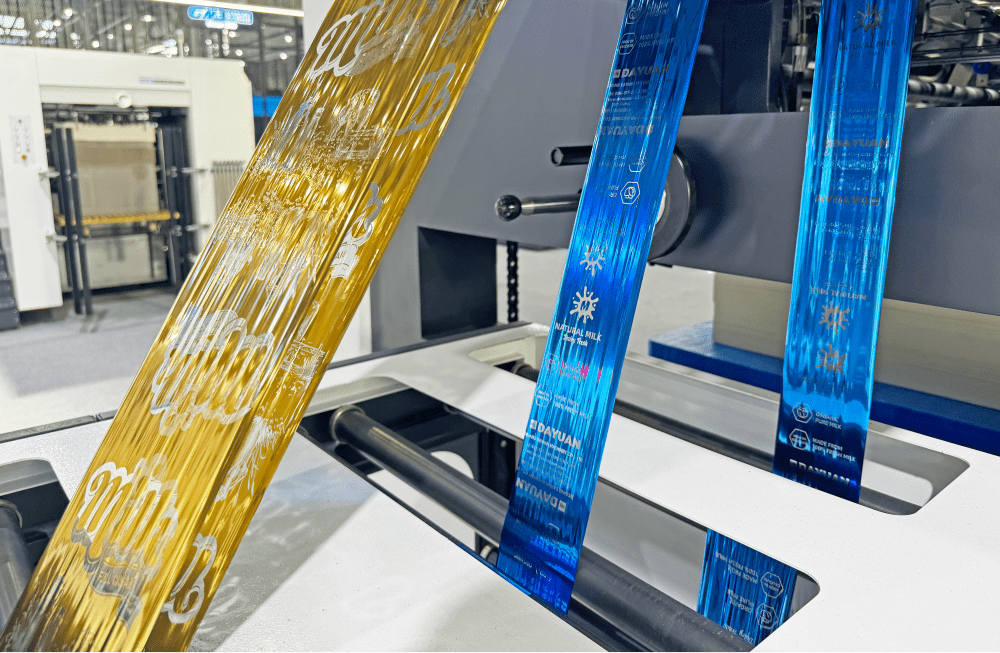

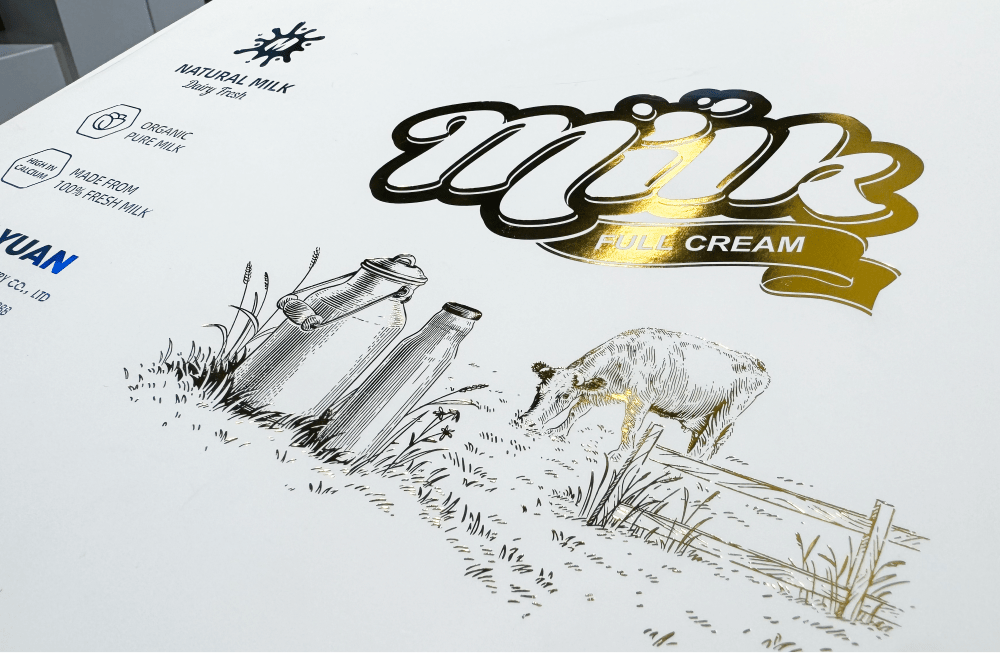

In the field of high-end packaging printing, the hot stamping process, with its premium metallic luster and luxury glossy finish, has become a crucial technique for elevating product quality.

However, common problems encountered during the complex hot foil stamping process have posed challenges, for which we provide solutions for many wrapping enterprises. Recently, Dayuan has systematically analyzed common issues in hot stamping and proposed practical solutions.

A.Hot Stamping Defects: Comprehensive Multi-Factor Solutions

-

Poor Foil Adhesion or Patchy Stamping Patterns: low temperature, inadequate pressure and ink crystallization are primary causes.

We recommend "three-step" strategy: First, check and adjust stamping temperature to optimal range. Second, appropriately increase stamping pressure. Finally, professionally treat crystallized ink layers.

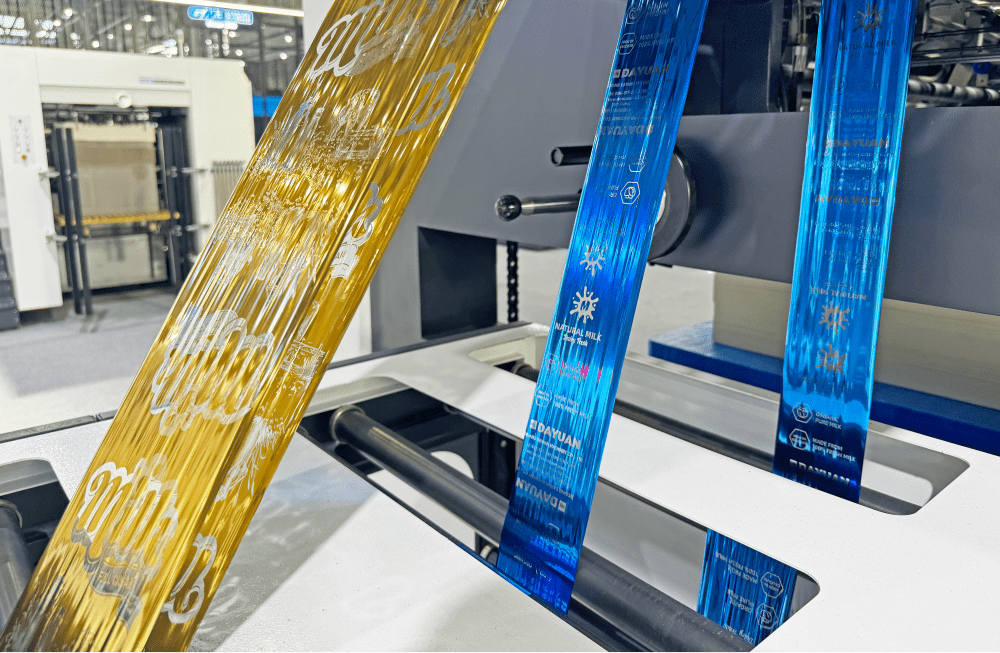

Special note: For large-area stamping, use premium hot stamping foil and use double pass foil stamping technique.

-

Blurred or Haloed Patterns: main cause is Excessive temperature.

The solution emphasizes temperature control for hot stamping: adjusting temperature according to foil characteristics and implementing cooling measures during machine downtime to prevent foil scorching

B.Print Quality Issues: Precision Control is Key

-

Stamping Burrs (Rough Edges): requires multi-dimensional control of pressure distribution across the stamping plate and precise plate cushioning accuracy.

Dayuan suggests our clients ensure stamping plates are perfectly leveled and firmly cushioned, maintain uniform stamping pressure, die cushioning must precisely match pattern contours without displacement.

-

Plate Smudging (Image Bleeding): temperature regulation is core solution.

Dayuan proposes operating within the recommended temperature range for the specific hot stamping foil, appropriately reduce stamping temperature when necessary, implement real-time temperature monitoring for consistency.

C.Process Stability Issues: Full-process Quality Management

- To address incomplete patterns, Dayuan recommends operators control hot stamping foil cutting precision, monitor feeding process stability, conduct regular plate condition inspections.

- This forms a complete quality control loop.

D.Reverse Pulling Phenomenon: Coordinated Optimization of Materials and Process

- The solution emphasizes a dual approach of "Material Selection + Process Optimization": Select premium-quality hot stamping foil and optimize foil stamping machine settings (dwell time and heat adjustment).

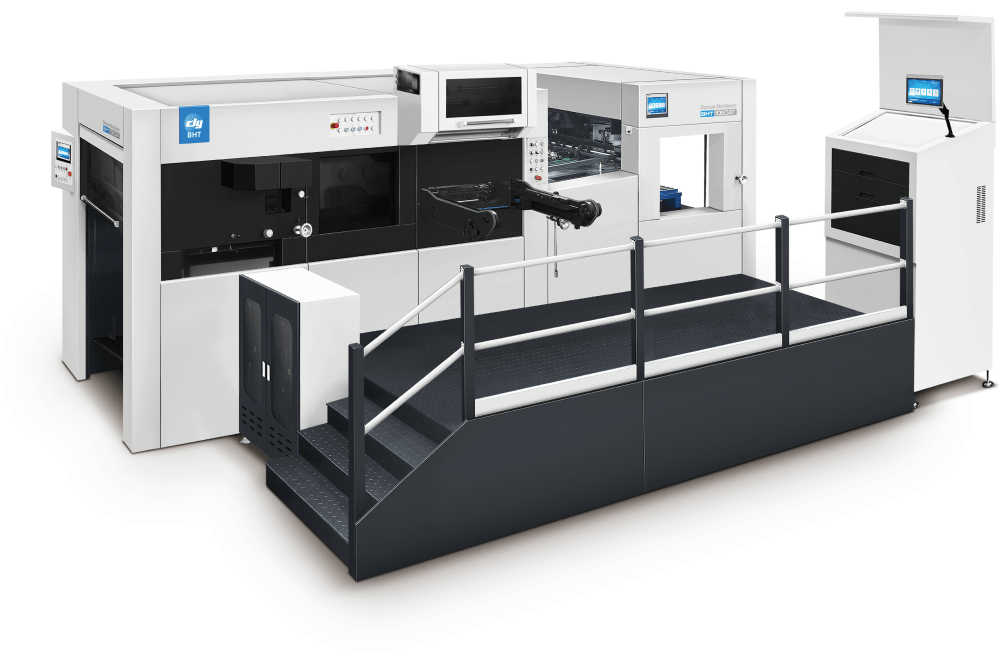

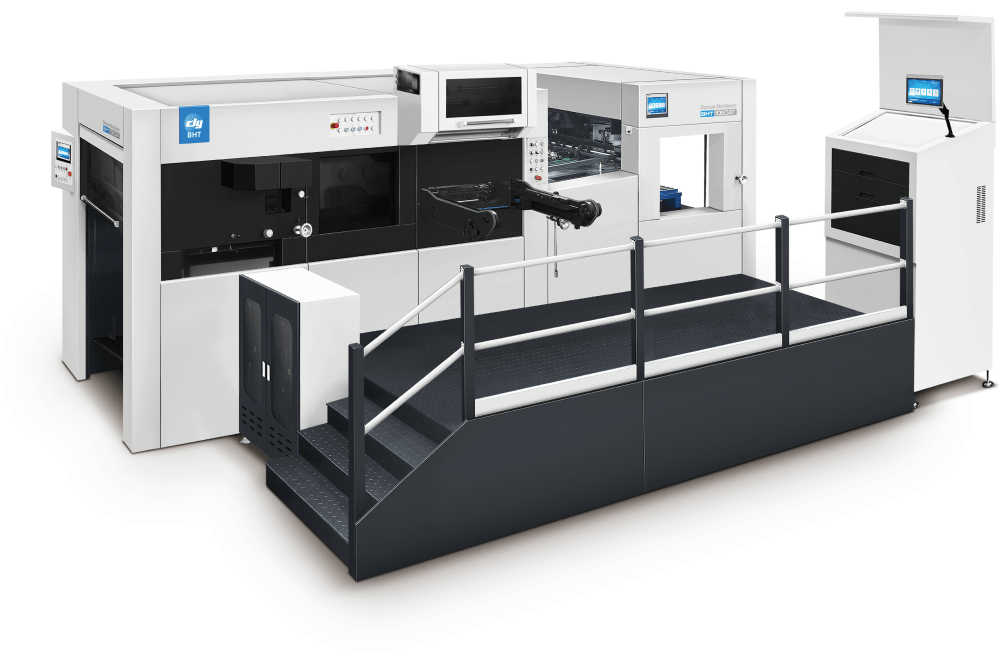

With the advancement of the post-press industry, hot stamping technology is evolving towards intelligent and precise development. Dayuan will advance hot foil stamping & die cutting machine and technology upgrades to help enterprises develop ISO-certified foil stamping workflows and provide comprehensive operator training. This initiative aims to enhance overall hot stamping quality and boost packaging premiumness and brand value.

Hot News

Hot News