Comprehensive Safety and Support Systems

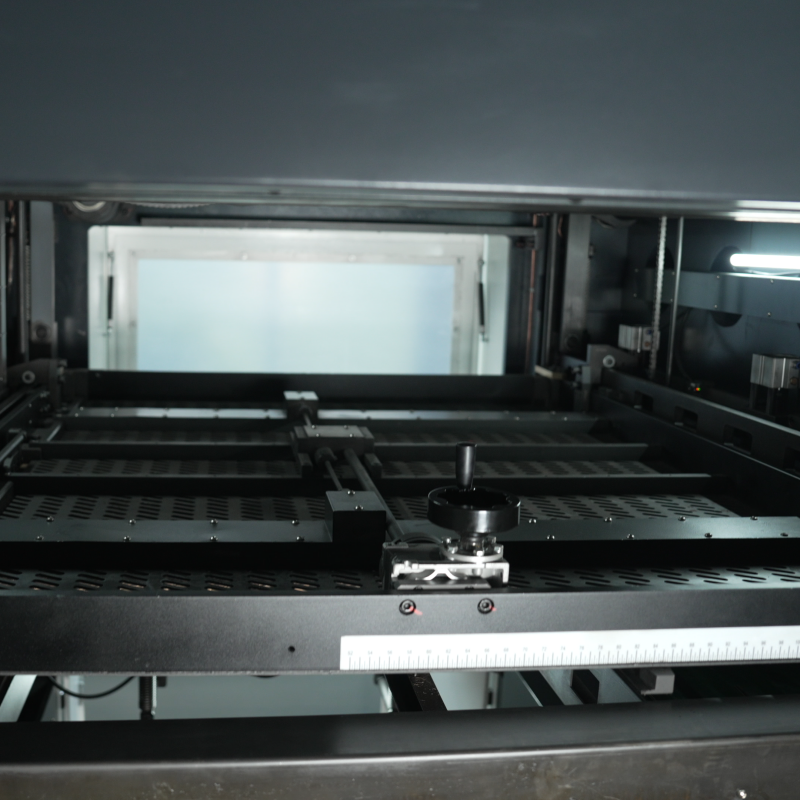

Safety and reliability are paramount in the manufacturer's design philosophy, evident in their comprehensive approach to operator protection and system support. Every machine incorporates multiple safety features, including light curtains, physical barriers, and emergency stop systems strategically placed for immediate access. The manufacturer provides extensive training programs and detailed documentation to ensure operators are well-versed in safe operating procedures. Remote diagnostic capabilities allow technical support teams to quickly identify and resolve issues, minimizing production interruptions. The manufacturer maintains a global network of service centers and parts warehouses, ensuring prompt support and maintenance when needed. Regular software updates and preventive maintenance programs help maintain optimal performance and extend equipment life.