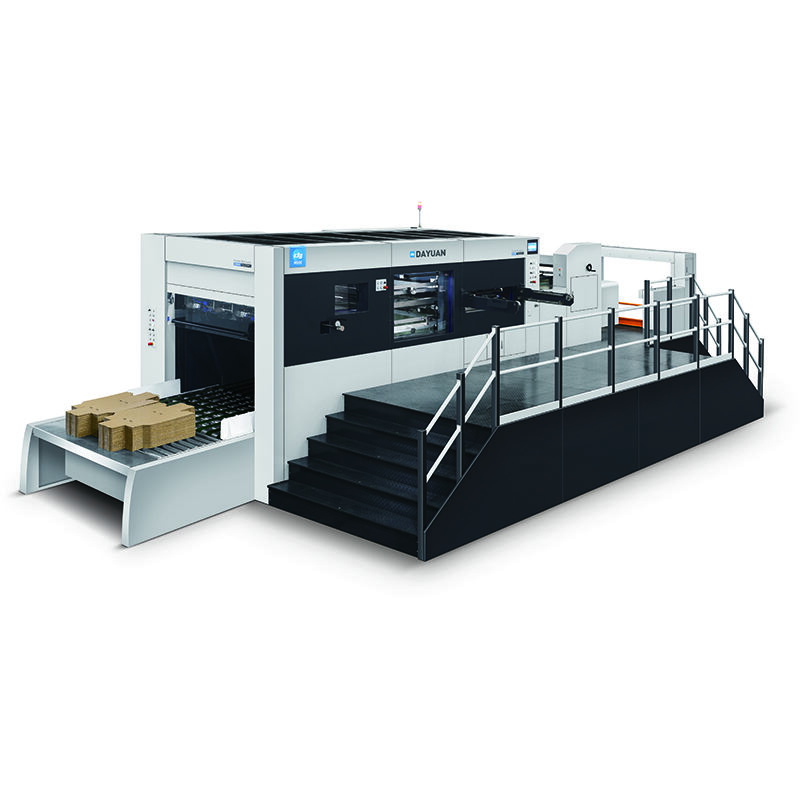

Advanced Automation and Precision Control

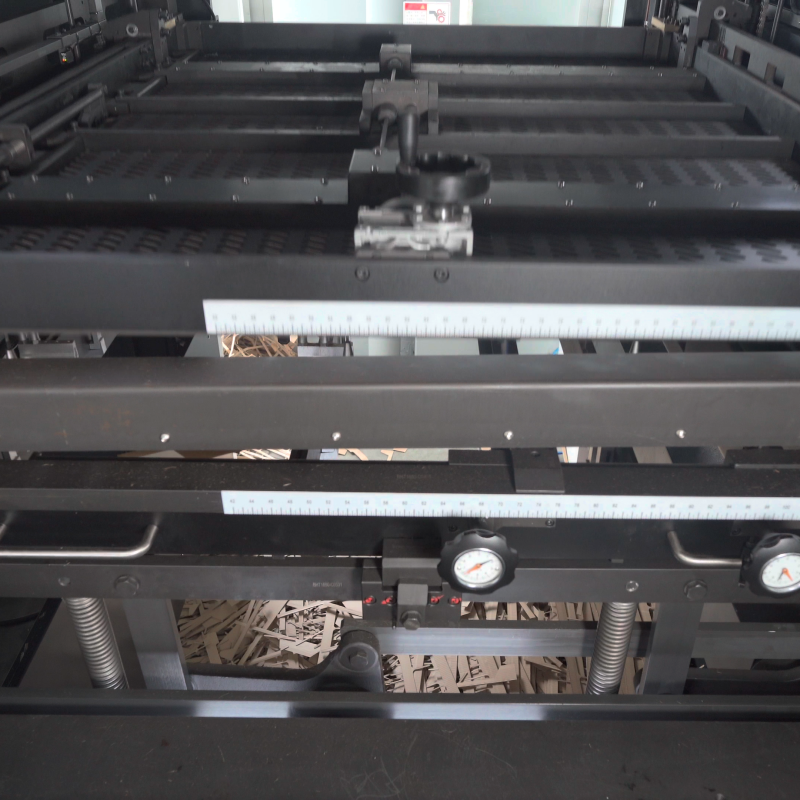

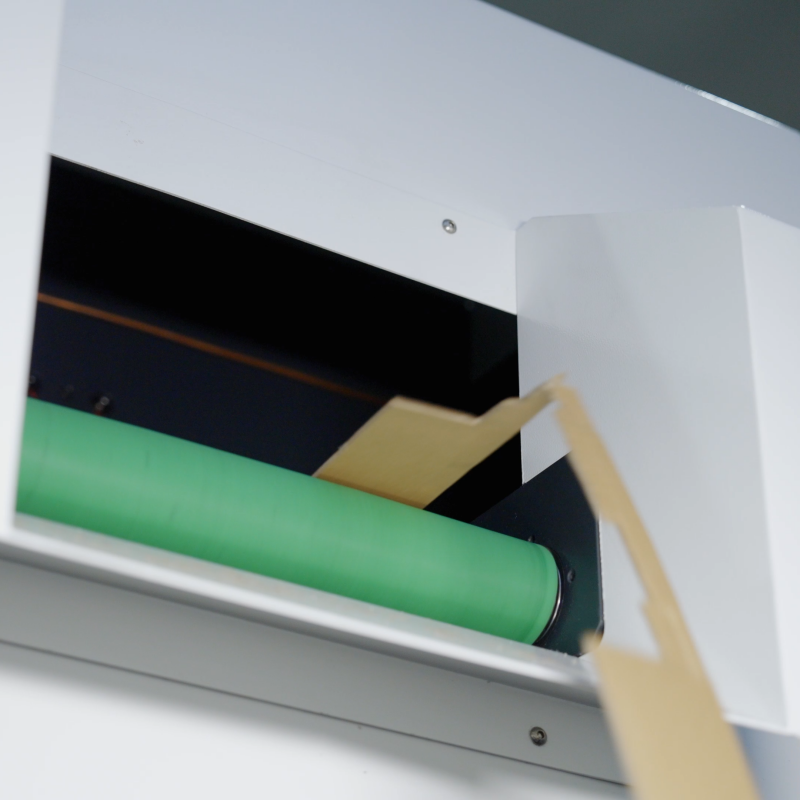

The leather die cutter factory excels in automation technology, featuring state-of-the-art computer-controlled cutting systems that deliver unprecedented precision and consistency. Each cutting station is equipped with advanced servo motors and pressure control systems that automatically adjust to varying leather thicknesses and textures. The cutting force precision, maintained within 0.1% tolerance, ensures clean, accurate cuts every time. The system's intelligent feedback mechanisms continuously monitor and adjust cutting parameters, preventing common issues like incomplete cuts or material damage. This advanced automation extends to material handling, with automated conveyor systems and robotic arms that minimize human error and maintain production flow. The facility's central control system provides real-time monitoring and adjustment capabilities, ensuring optimal performance across all production lines.