Multi-Channel Foil Feeding System

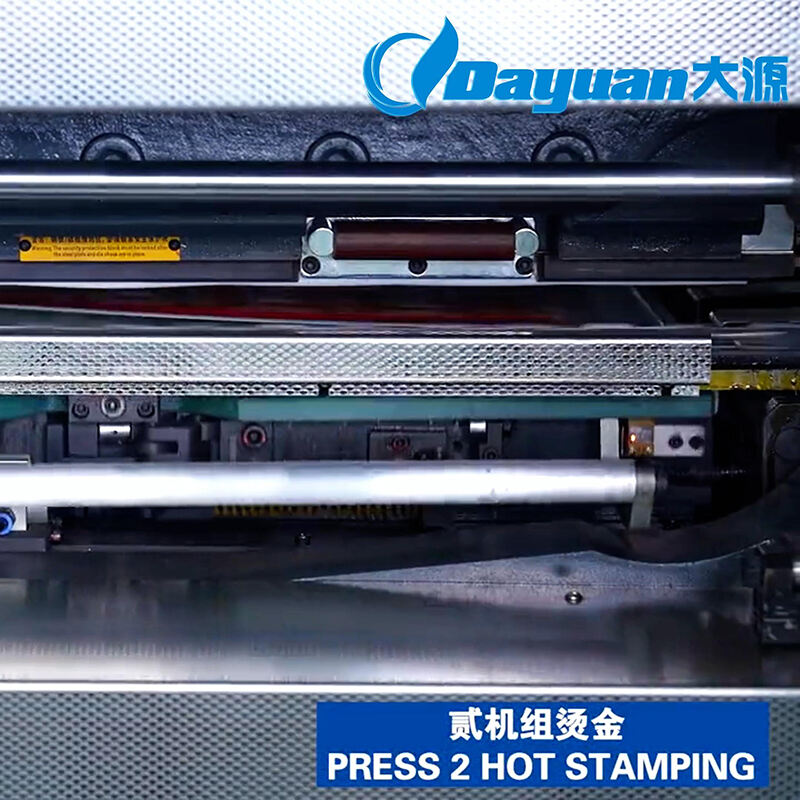

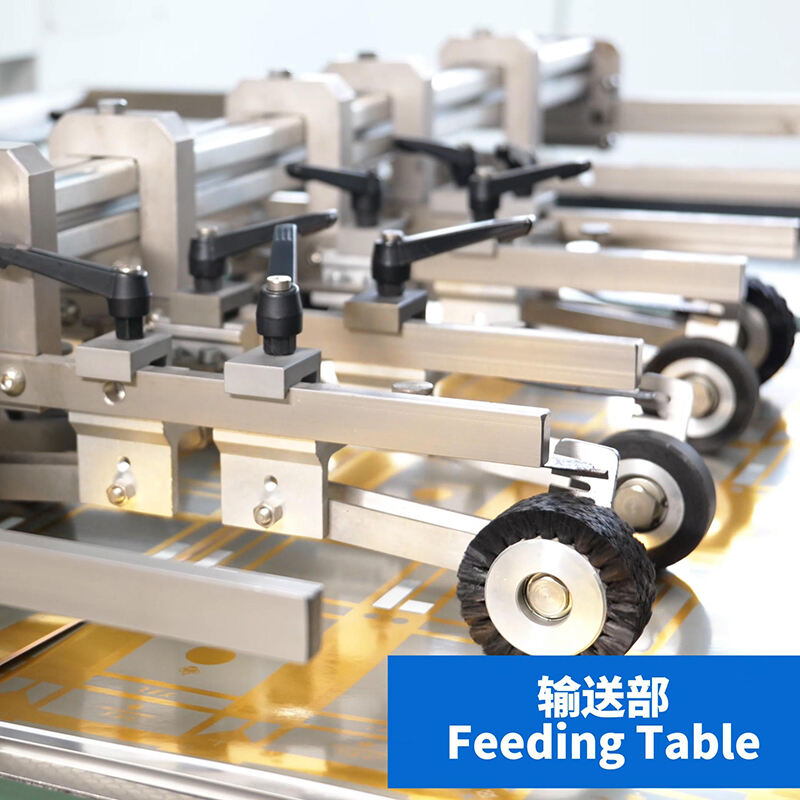

The multi-channel foil feeding system revolutionizes the capabilities of hot foil stamping operations by enabling simultaneous application of multiple foil colors or types. This sophisticated system features independently controlled foil channels, each equipped with precise tension control and automated advancement mechanisms. The system's intelligent foil management reduces waste by optimizing foil usage through accurate positioning and minimal spacing between impressions. Advanced foil tracking ensures proper alignment throughout the production run, while automatic splicing capabilities allow for continuous operation during foil roll changes. The system includes specialized sensors that monitor foil tension and position, preventing wrinkles and ensuring smooth application. The multi-channel design enables complex decorative effects through the combination of different foil types, including metallic, holographic, and pigmented foils, all in a single pass.