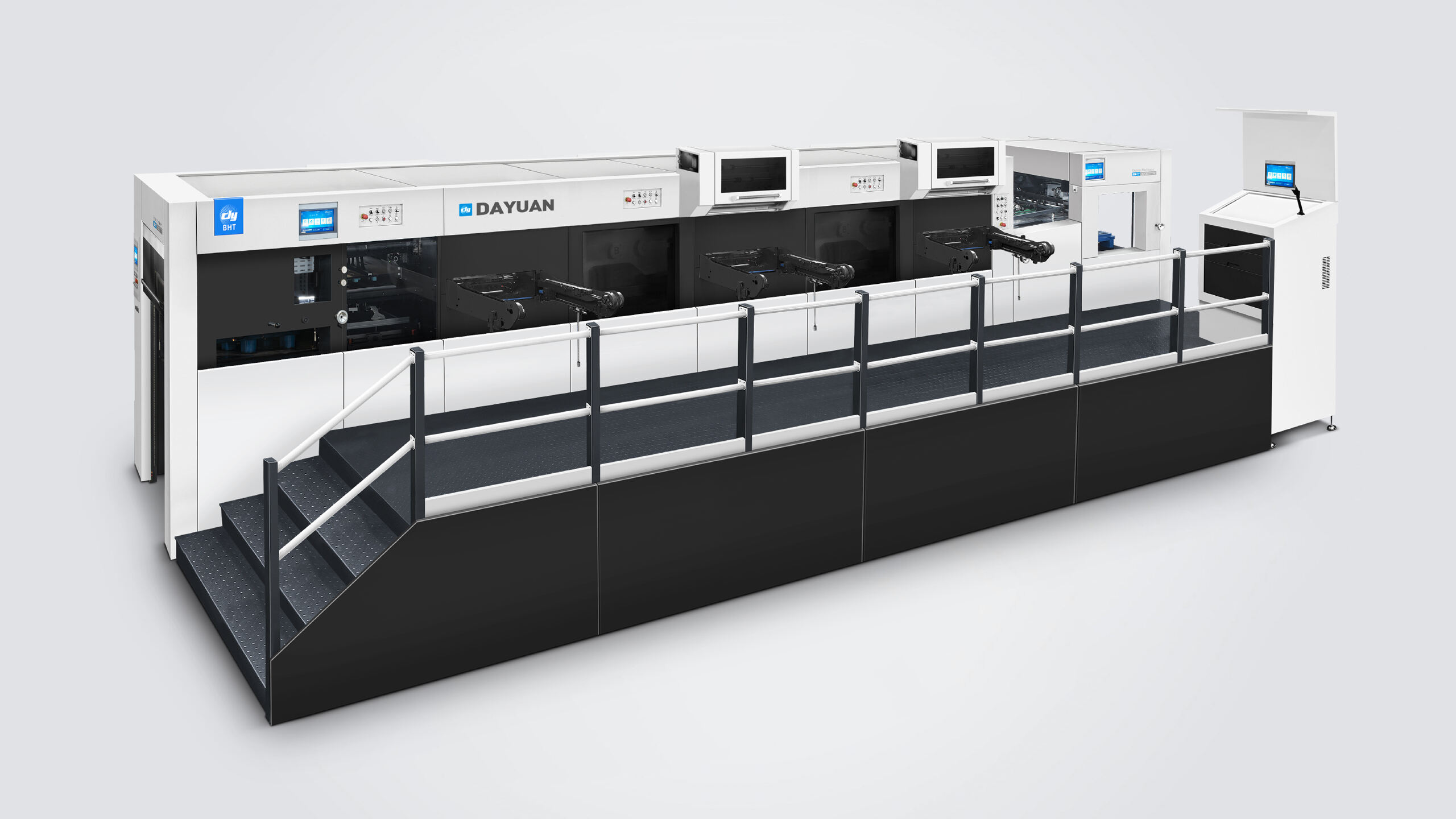

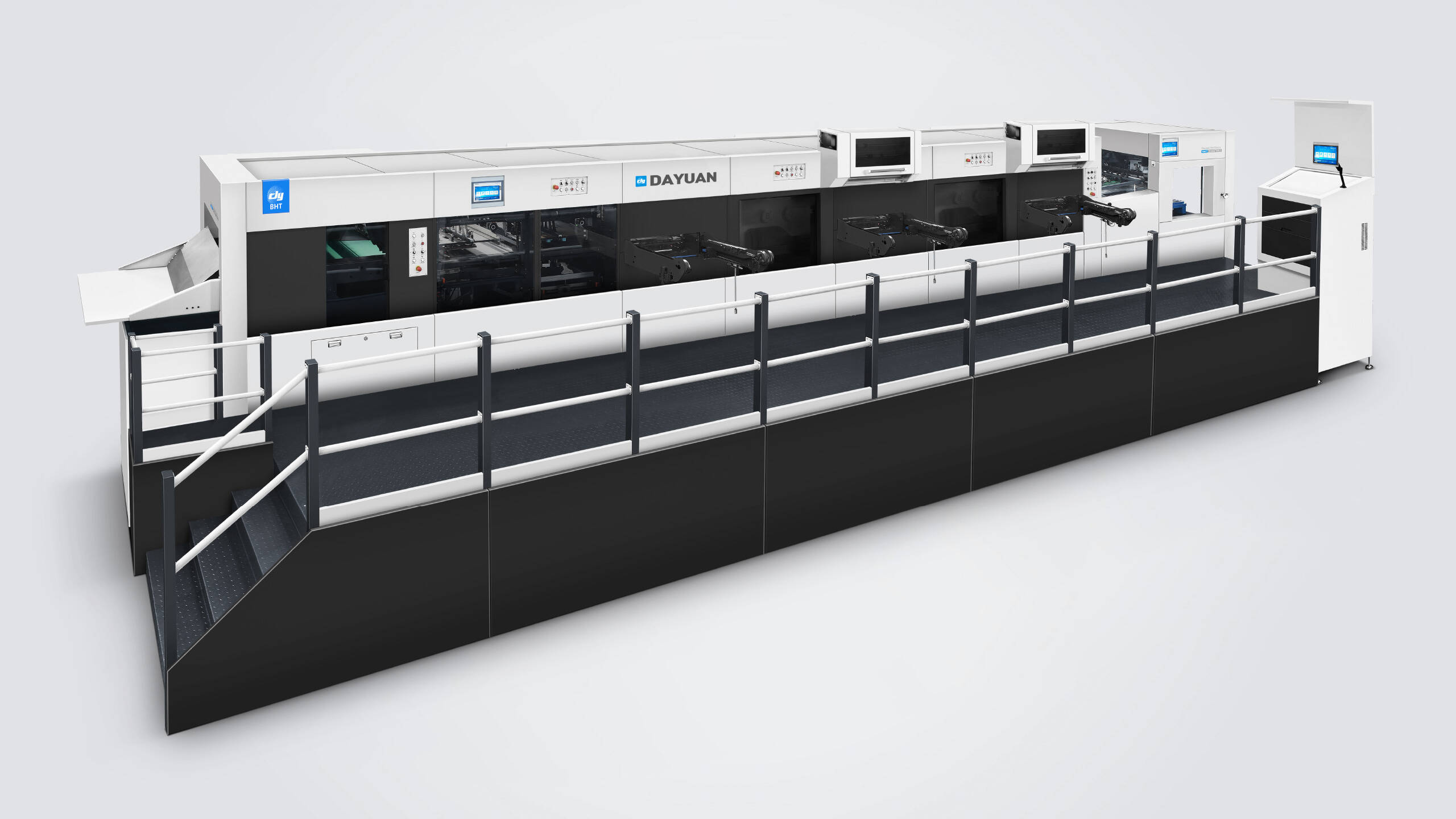

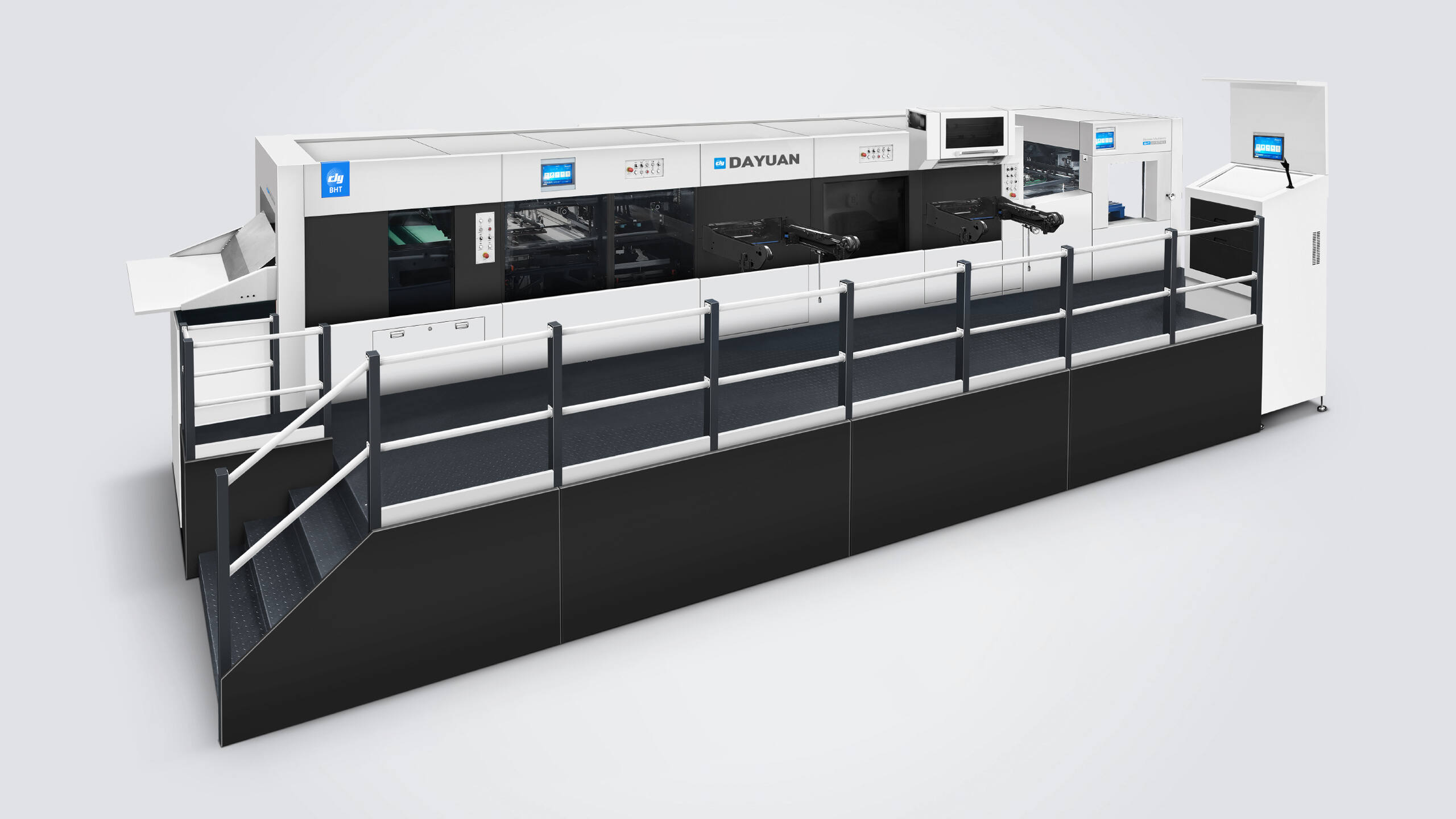

BHT-3S1060TTRC

TRIOPRESS Automatic High Speed Hot Stamping & Die Cutting Machine With Stripping

- Invention patent: the world’s first three-station die-cutting machine

- Flexible customization for exact product requirements

- Operate with 50% less labor and space while achieving speeds up to 6,200 sheets/h (40% faster than industry standards)

- Overview

- Technical Parameters

- Related Products

- FAQ

Product Description

Dayuan BHT-series TRIOPRESS Automatic High Speed Hot Stamping & Die Cutting Machine With Stripping supports one-pass processing for hot foil stamping, die cutting and stripping, enabling efficient and integrated production. Ideal for paper packaging products with complex, large-area foil stamping and deep embossing effects, it delivers exceptional value and competitiveness to customers, maximizing productivity while reducing labor costs. It is the premier choice for high-end post-press markets.

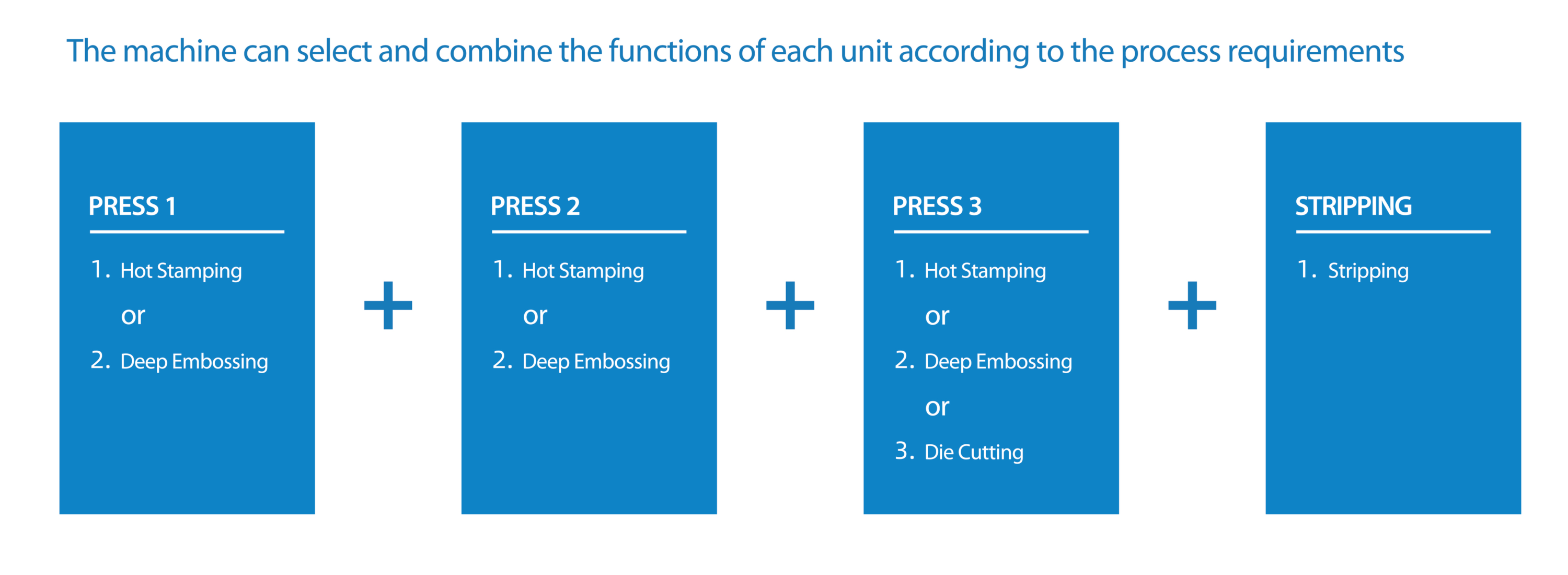

Flexible Customization:

• Modular process configuration tailored to product requirements, with each unit independently controlled by servo motors for optional single-unit operation.

• Features holographic foil stamping, triple foil stamping, deep embossing, die cutting and waste stripping to meet diverse production needs and significantly enhance efficiency.

Reliable Performance:

• Maximum speed: 6,200 sheets/hour; maximum pressure: 600 tons.

• Equipped with a proprietary foil stamping control system and foil feeding system, it supports both horizontal and vertical stamping to meet premium quality demands, with hot stamping accuracy of ±0.1mm.

• Lightweight yet durable carbon fiber gripper bars ensure extended machine lifespan.

• Patented gripper bar rear-positioning servo control system guarantees permanent precision of ±0.075mm.

Excellent Versatility:

• Supports hot stamping and embossing on various materials

• Ideal for processing complex structure graphics in the printing and packaging industry.

• Enables easy and rapid switching between hot foil stamping and die cutting processes.

Outstanding Cost-Effectiveness:

• Robust cast-iron frame ensures stability.

• Supports quick setup and fast changeover with microadjustment devices.

• User-friendly human-machine interface for intuitive and efficient operation.

• Comprehensive spare parts supply chain for after-sales support.

|

|

|

| Feeder(4 suction and 6 delivery) |

Ultrasonic double sheet detector |

Paper conveying unit |

|

|

|

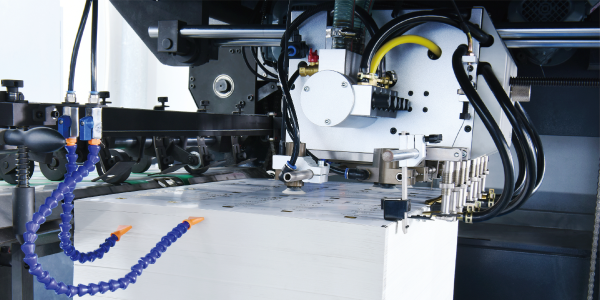

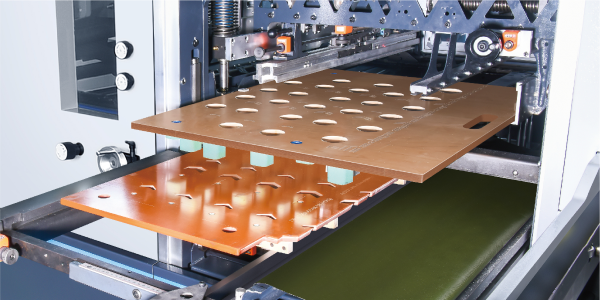

| Carbon fiber gripper bar |

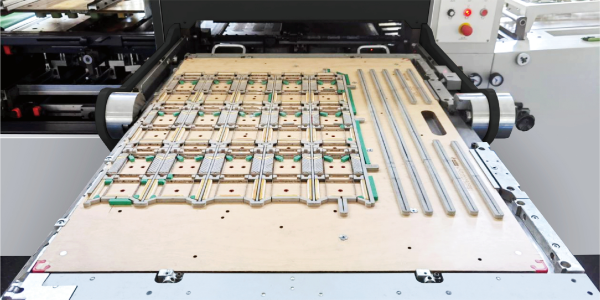

Micro-adjustable die cutting plate |

Micro-adjustable frame with quick locking device |

|

|

|

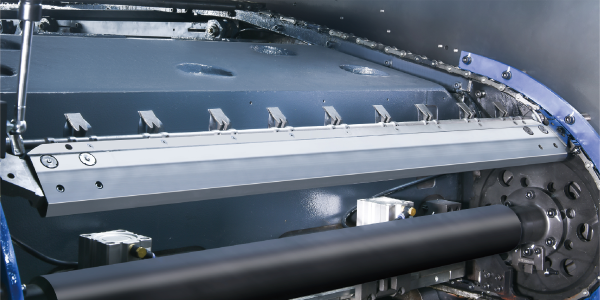

| Servo controlled gripper bar positioning device |

Timing belt driven device |

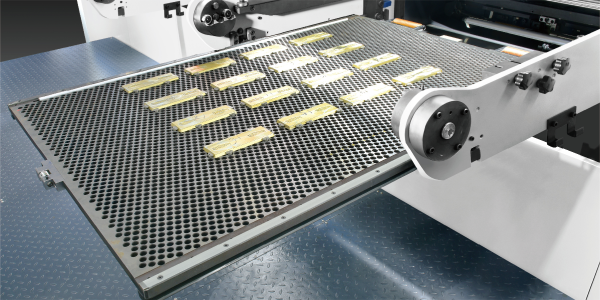

Micro-adjustable honeycomb plate |

|

|

|

| Advanced plate quick locking device |

Gripper margin stripping device |

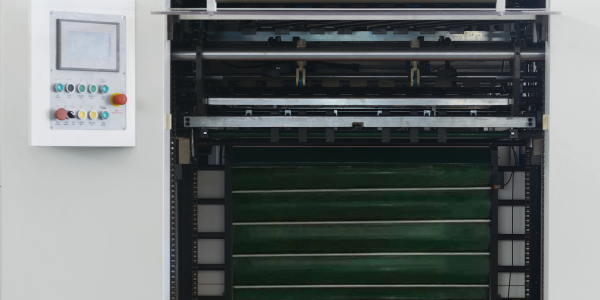

Non-stop roll-up curtain type paper delivery device |

|

|

|

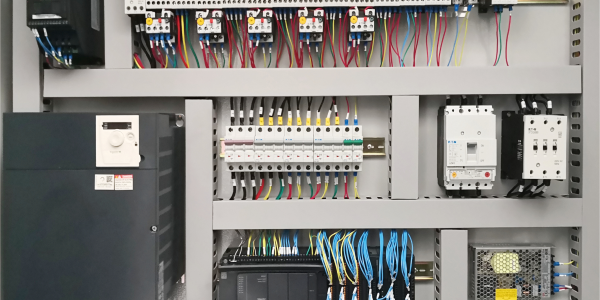

| Electrical unit |

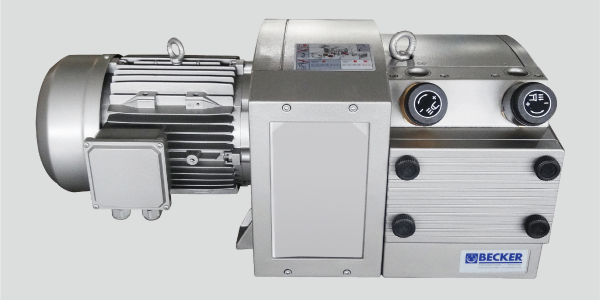

Germany vacuum pump |

Auto lubrication system |

|

||

| Main unit cooling/lubrication mechanism |

Technical Parameters

|

Model |

BHT-3S1060TTT |

BHT-3S1060TTRC BHT-3S1060TTMC |

BHT-3S1060TRRC BHT-3S1060TRMC |

BHT-3S1060RRRC BHT-3S1060RRMC |

|

Maximum Sheet Size |

1060×760mm |

1060×760mm |

1060×760mm |

1060×760mm |

|

Minimum Sheet Size |

400×350mm |

400×350mm |

400×350mm |

400×350mm |

|

Maximum Cutting Size |

1060×745mm |

1060×745mm |

1060×745m |

1060×745mm |

|

Maximum Stamping Size |

1060×740mm |

1060×740mm |

1060×740mm |

/ |

|

Maximum Heating Size |

1060×740mm |

1060×740mm |

1060×740mm |

1060×740mm |

|

Minimum Gripper Margin |

9-17mm |

9-17mm |

9-17mm |

9-17mm |

|

Minimum Width of Double Cuts |

/ |

10-18mm |

10-18mm |

10-18mm |

|

Inner Chase Size |

1080×790mm |

1080×790mm |

1080×770mm |

1080×770mm |

|

Stock Range |

Cardboard: 80-2000g/m²,0.1-2mm |

Cardboard: 80-2000g/m², 0.1-2mm |

Cardboard: 80-2000g/m², 0.1-2mm |

Cardboard: 80-2000g/m², 0.1-2mm |

|

Die Cutting Accuracy |

≤±0.075mm |

≤±0.075mm |

≤±0.075mm |

≤±0.075mm |

|

Stamping Accuracy |

≤±0.1mm |

≤±0.1mm |

≤±0.1mm |

/ |

|

Heating Accuracy |

≤±0.075mm |

≤±0.075mm |

≤±0.075mm |

≤±0.075mm |

|

Press 1 Max.Cutting Force |

600T |

600T |

600T |

600T |

|

Press 2 Max.Cutting Force |

600T |

600T |

600T |

600T |

|

Press 3 Max.Cutting Force |

600T |

600T / 300T |

600T / 300T |

600T / 300T |

|

Max.Working Speed |

6200s/h |

6200s/h |

6200s/h |

6200s/h |

|

Maximum Pile Height at Feeder-Normal Mode |

1800mm |

1800mm |

1800mm |

1800mm |

|

Maximum Pile Height at Feeder-Non-stop Mode |

1520mm |

1520mm |

1520mm |

1520mm |

|

Maximum Pile Height at Delivery |

1580mm |

1580mm |

1580mm |

1580mm |

|

Max.Gold Doil Diameter |

φ250mm Longitudinal,φ200mm Transeversal |

φ250mm Longitudinal,φ200mm Transeversal |

φ250mm Longitudinal,φ200mm Transeversal |

/ |

|

Electric-heated System |

20 Heating zones,40-180℃ Adjustable |

20 Heating zones,40-180℃ Adjustable |

20 Heating zones,40-180℃ Adjustable |

20 Heating zones,40-180℃ Adjustable |

|

Foil Width |

20-1060mm |

20-1060mm |

20-1060mm |

/ |

|

Press 1 Foil Advance Shafts |

3 Longitudinal+2 Transversal |

3 Longitudinal+2 Transversal |

3 Longitudinal+2 Transversal |

Electric-heated System |

|

Press 2 Foil Advance Shafts |

3 Longitudinal+2 Transversal |

3 Longitudinal+2 Transversal |

Electric-heated System |

Electric-heated System |

|

Press 3 Foil Advance Shafts |

3 Longitudinal+2 Transversal |

Electric-heated System+Stripping (TTRC) |

Electric-heated System+Stripping (TTRC) |

Electric-heated System+Stripping (RRRC) |

|

Die Cutting+Stripping (TTMC) |

Die Cutting+Stripping (TRMC) |

Die Cutting+Stripping (RRMC) |

||

|

Full Load Wattage |

177KW |

165KW / 150KW |

129KW / 99KW |

103KW / 91KW |

|

Air Requirement |

0.6-0.7MPa,≥1m³/min |

0.6-0.7MPa,≥1m³/min |

0.6-0.7MPa,≥1m³/min |

0.6-0.7MPa,≥1m³/min |

|

Net Weight of Machine |

63T |

62T / 61T |

61T / 60T |

59T / 58T |

|

Machine Dimensions(Including Die Preloader)(L×W×H) |

11774×7613×2909mm |

11774×7613×2909mm |

11774×7613×2909mm |

11774×7613×2891mm |