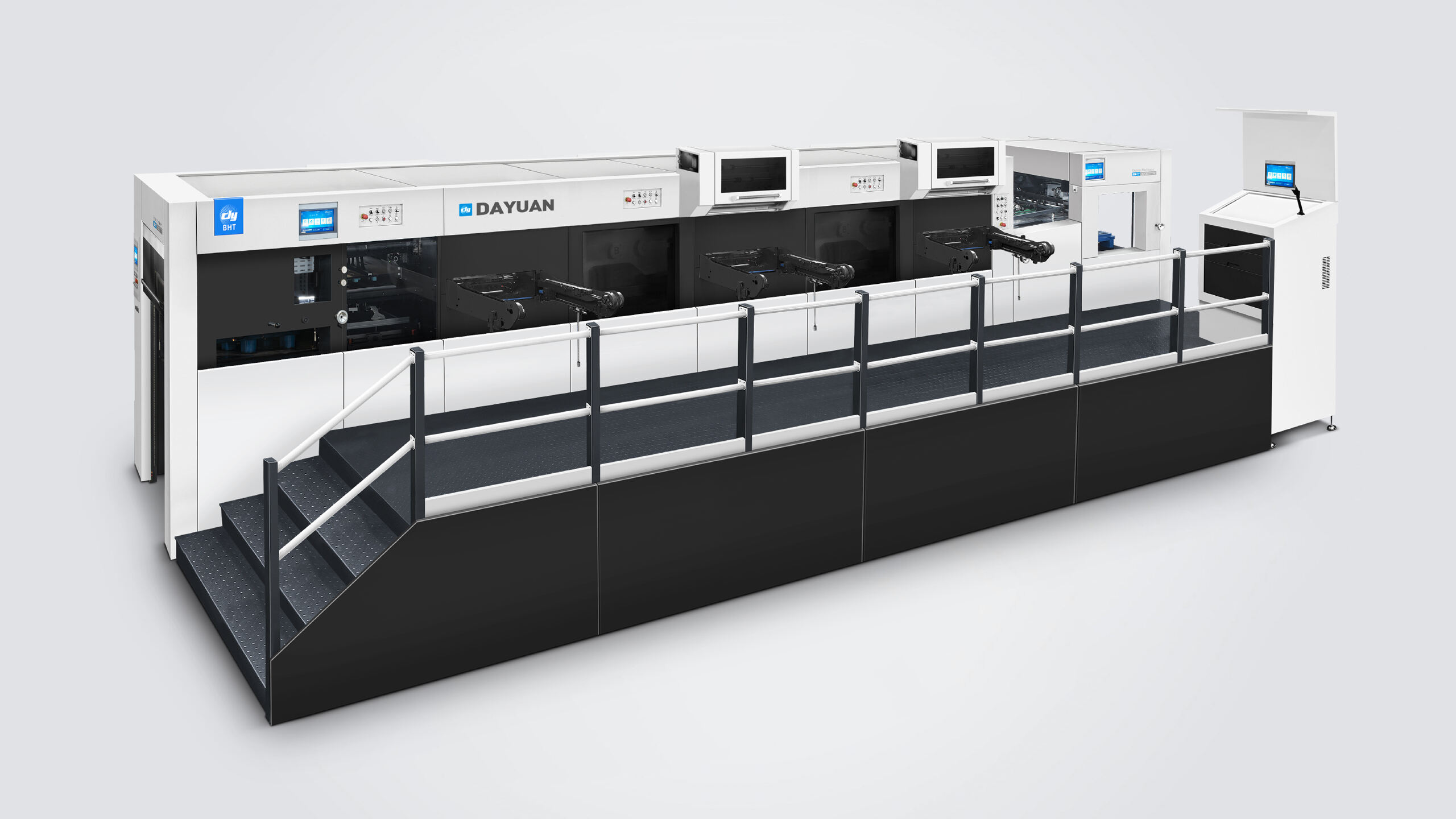

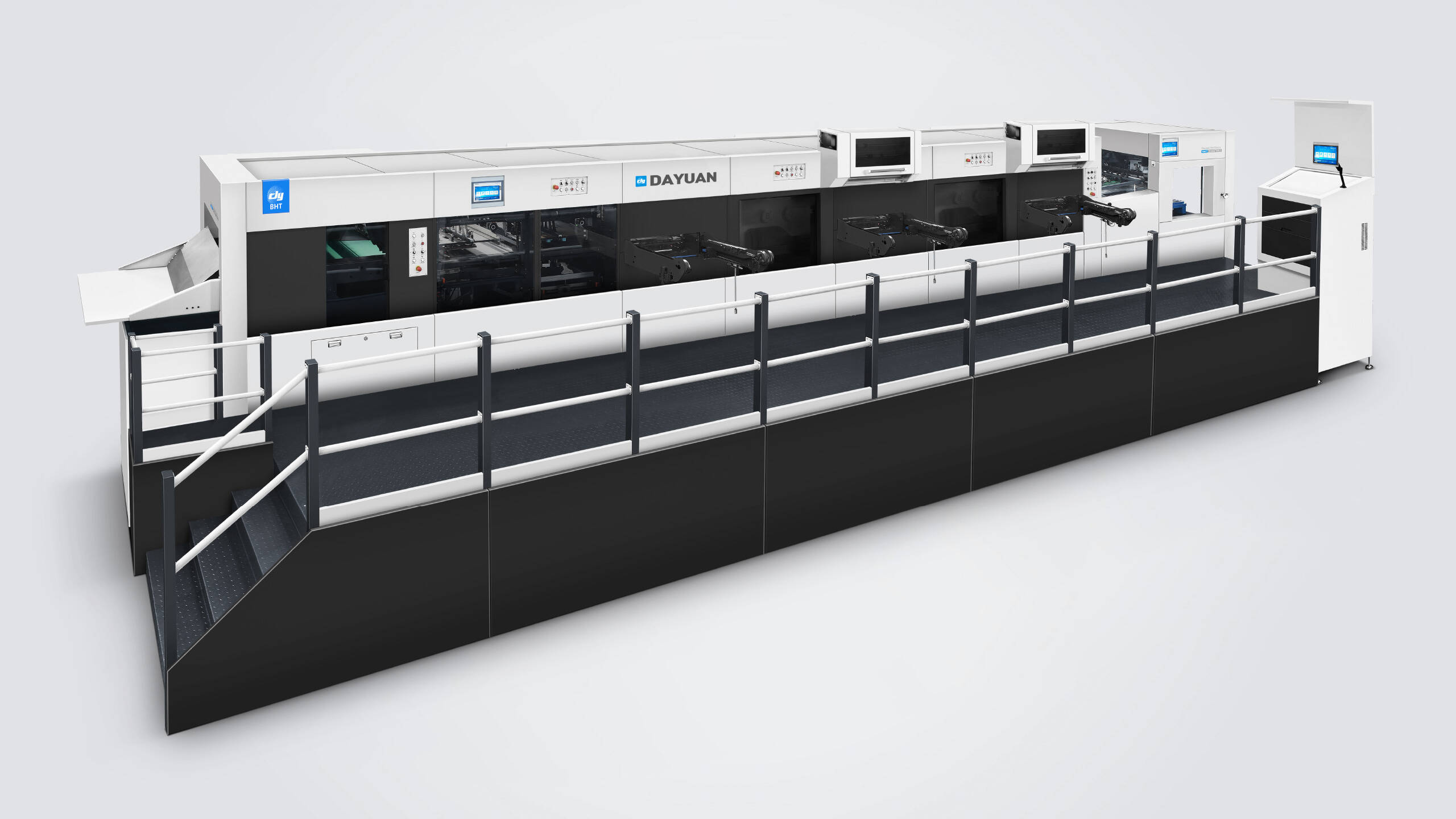

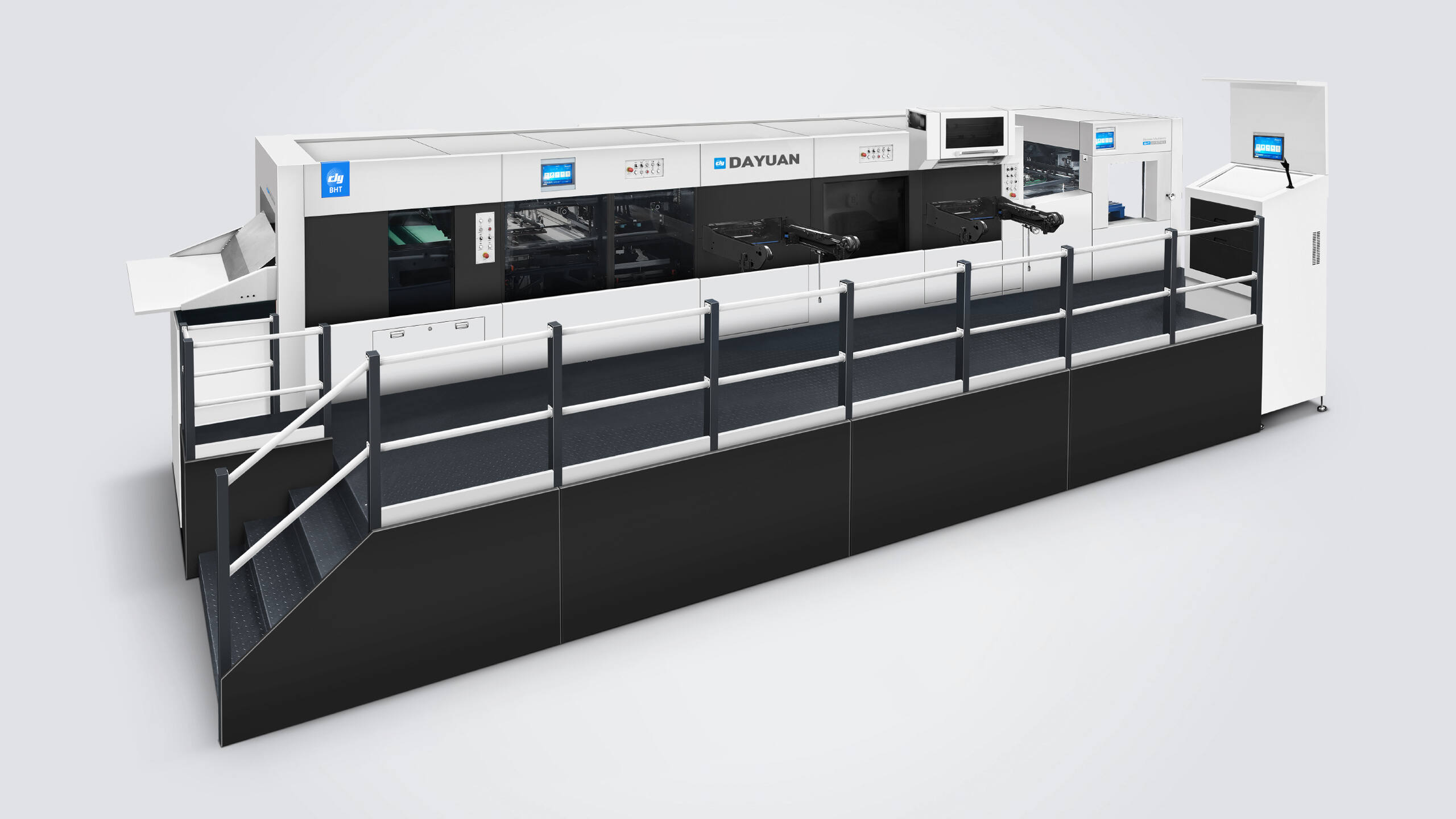

BHT-1060AT

Automatic Hot Foil Stamping & Die Cutting Machine(Heavy Duty)

- Specially designed for hot stamping & deep embossing in high-end paper packaging

- Maximum speed: 8000 sheets/h

- Maximum working pressure: 600T

- Overview

- Technical Parameters

- Related Products

- FAQ

Product Description

Dayuan BHT-1060AT Automatic Hot Foil Stamping & Die Cutting Machine meets all your production needs. This automatic hot stamping machine delivers exceptional precision, high efficiency, and superior product quality, making it ideal for high-end paper packaging requiring large-area foil stamping and embossing such as premium liquor packaging, luxury gift boxes, high-end electronics packaging and elegant paper bags

Reliable Performance:

• Maximum speed: 8,000 sheets/hour; maximum pressure: 600 tons.

• Equipped with a proprietary foil stamping control system and foil feeding system, it supports both horizontal and vertical stamping to meet premium quality demands, with hot stamping accuracy of ±0.1mm.

• Lightweight yet durable carbon fiber gripper bars ensure extended machine lifespan.

• Patented gripper bar rear-positioning servo control system guarantees permanent precision of ±0.075mm.

Excellent Versatility:

• Supports hot stamping and embossing on various materials.

• Ideal for processing complex structure graphics in the printing and packaging industry.

• Enables easy and rapid switching between hot foil stamping and die cutting processes.

Outstanding Cost-Effectiveness:

• Robust cast-iron frame ensures stability.

• Supports quick setup and fast changeover with microadjustment devices.

• User-friendly human-machine interface for intuitive and efficient operation.

• Comprehensive spare parts supply chain for after-sales support.

|

|

|

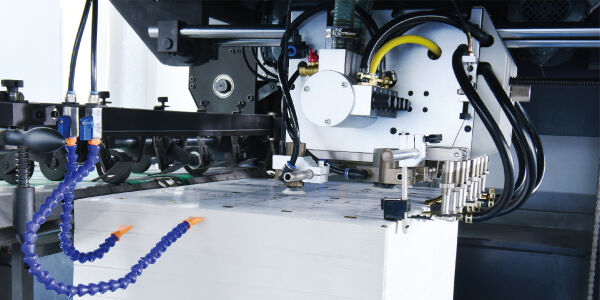

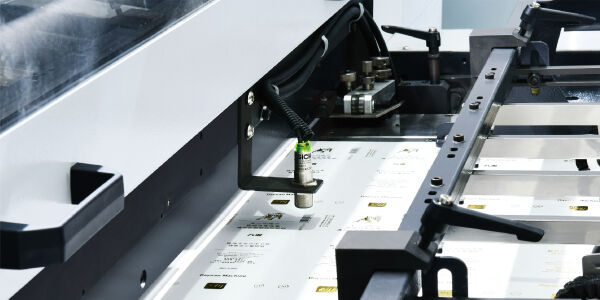

| Feeder(4 suction and 6 delivery) |

Ultrasonic double sheet detector |

Paper conveying unit |

|

|

|

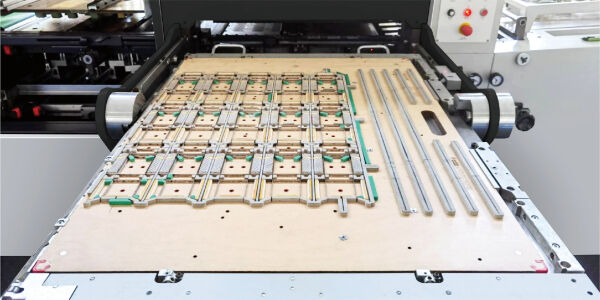

| Carbon fiber gripper bar |

Micro-adjustable die cutting plate |

Micro-adjustable frame with quick locking device |

|

|

|

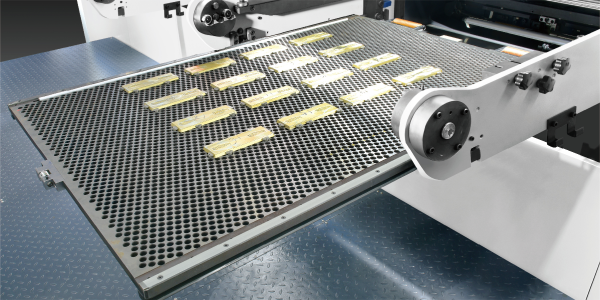

| Servo controlled gripper bar positioning device |

Timing belt driven device |

Micro-adjustable honeycomb plate |

|

|

|

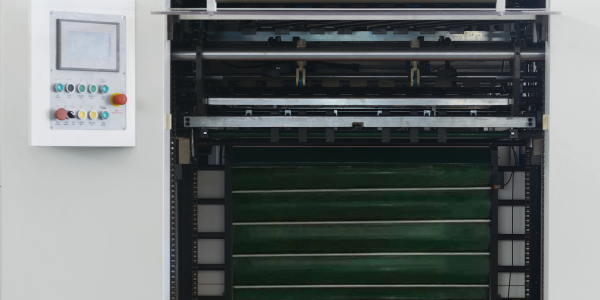

| Non-stop roll-up curtain type paper delivery device |

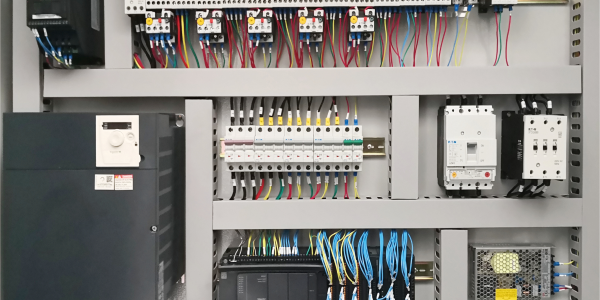

Electrical unit |

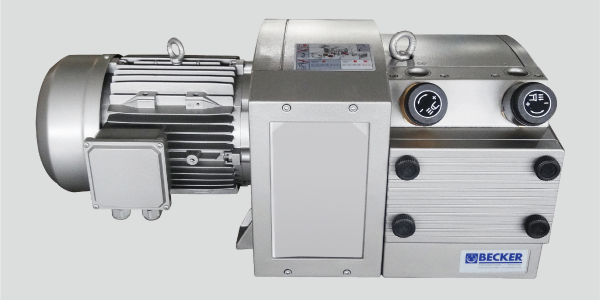

Germany vacuum pump |

|

|

|

| Auto lubrication system |

Main unit cooling/lubrication mechanism |

Technical Parameters

|

Model |

BHT-1060AT |

|

Maximum Sheet Size |

1060×760mm |

|

Minimum Sheet Size |

400×350mm |

|

Maximum Cutting Size |

1060×745mm |

|

Maximum Stamping Size |

1060×745mm |

|

Minimum Gripper Margin |

9-17mm |

|

Cutting Rule Height |

23.8mm |

|

Inner Chase Size |

1080×790mm |

|

Stock Range |

Cardboard: 80-2000g/m²,0.1-2mm |

|

Die Cutting Accuracy |

≤±0.075mm |

|

stamping accuracy |

≤±0.1mm |

|

Embossing Accuracy |

≤±0.075mm |

|

Max.Cutting Force |

600T |

|

Max.Working Speed |

8000s/h |

|

Maximum Feeder Pile Height |

1630mm |

|

Maximum Delivery Pile Height |

1480mm |

|

Max.Gold Doil Diameter |

φ250mm Longitudinal,φ200mm Transeversal |

|

Electric-heated System |

20 Heating zones, 40-180℃ Adjustable |

|

Foil Width |

20-1060mm |

|

Main Motor Power |

15KW |

|

Full Load Wattage |

56KW |

|

Air Requirement |

0.6-0.7MPa,≥0.37m³/min |

|

Net Weight of Machine |

24T |

|

Machine Dimensions(L×W×H) |

7715×4727×2683mm |

|

Machine Dimensions(Including Die Preloader)(L×W×H) |

7715×5627×2683mm |