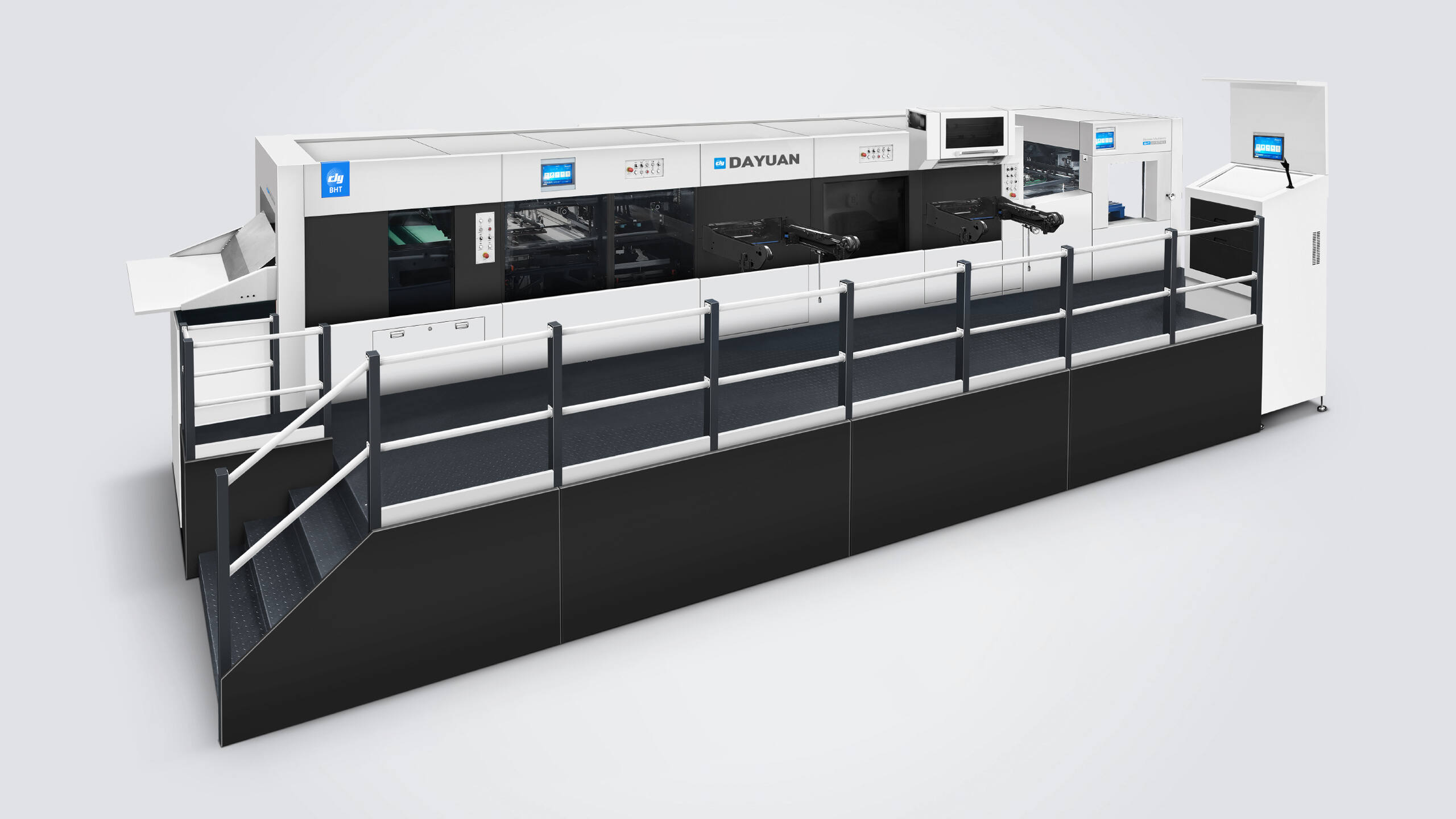

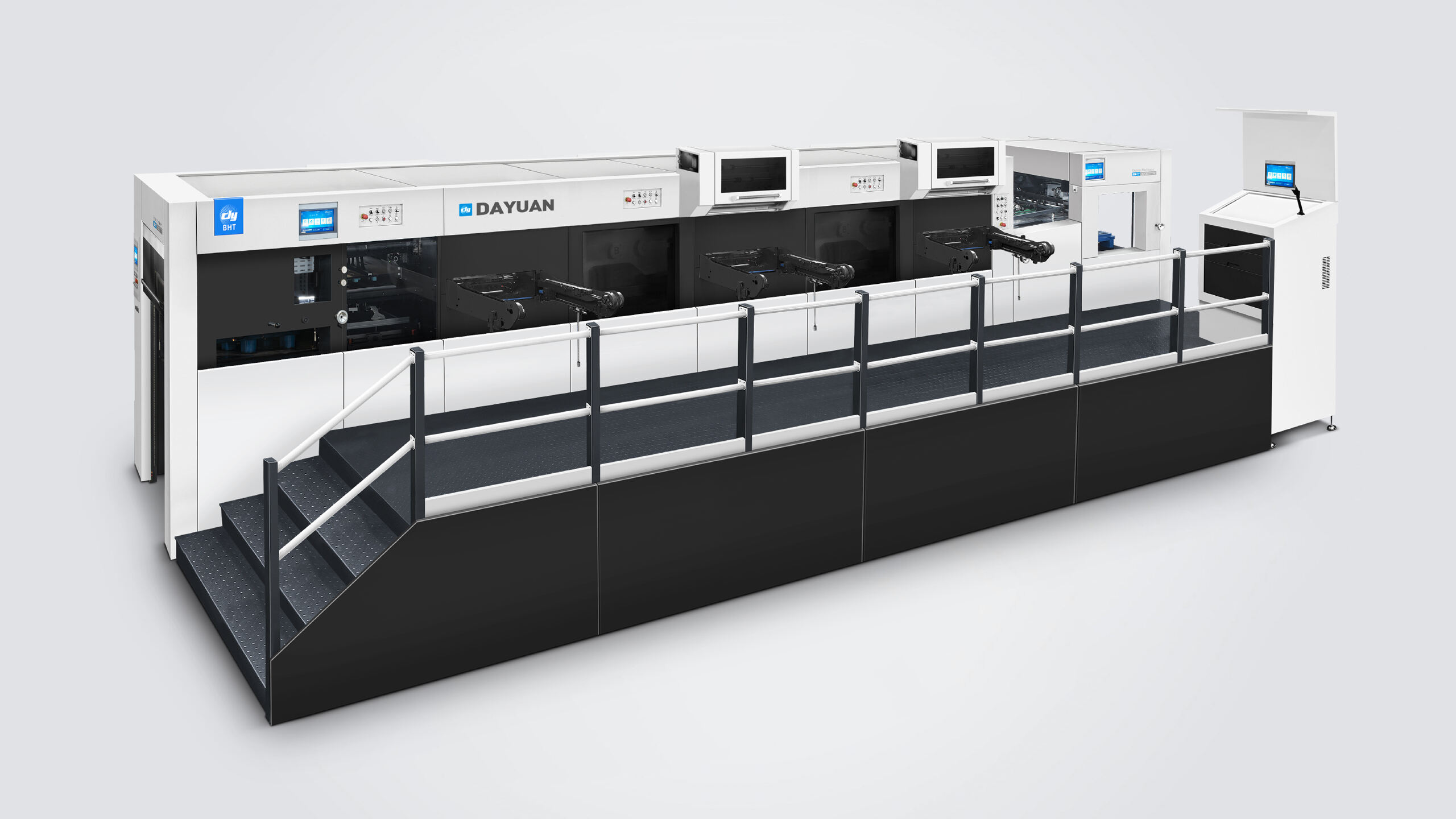

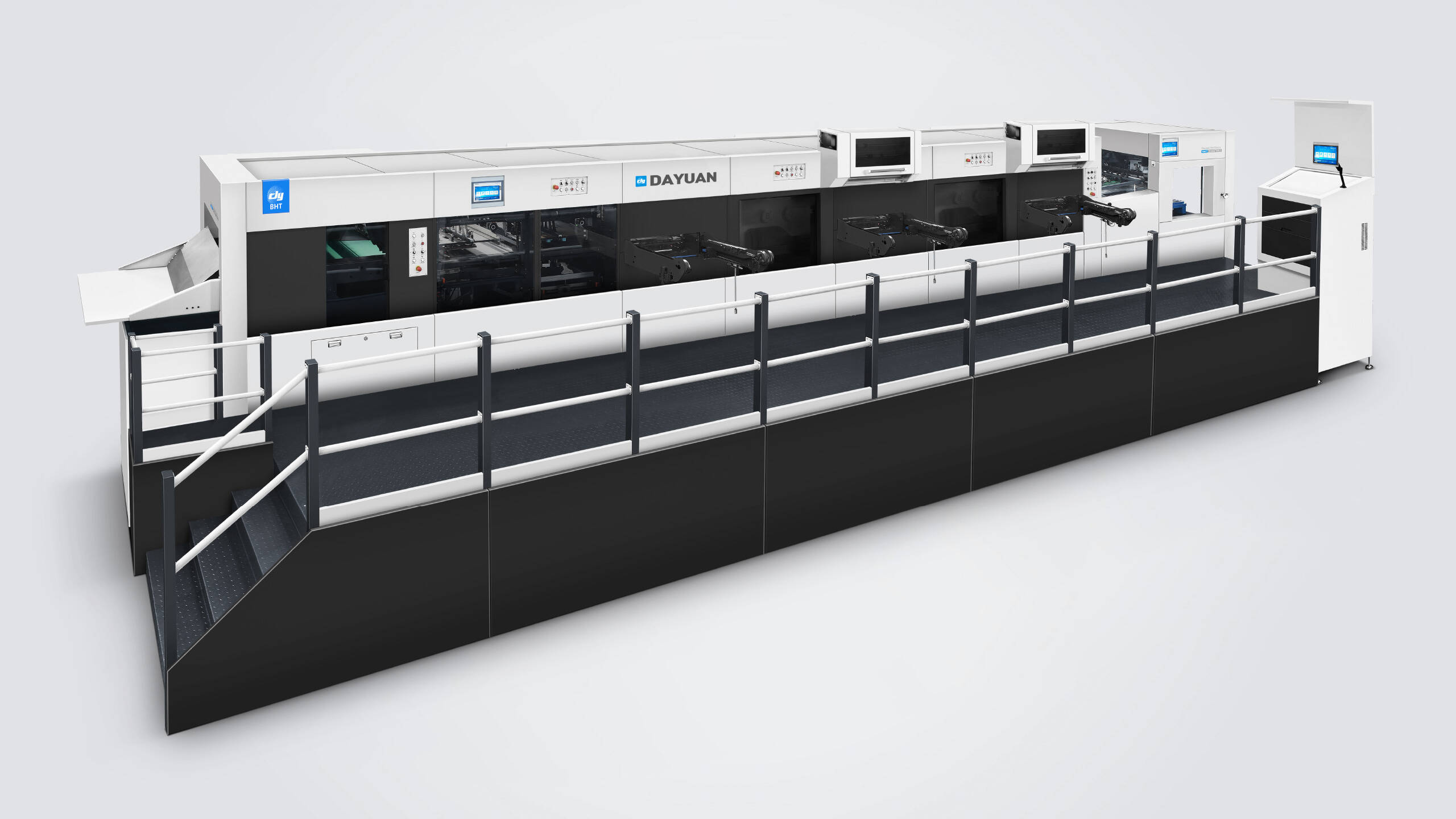

BHT-2S1060TRSCE

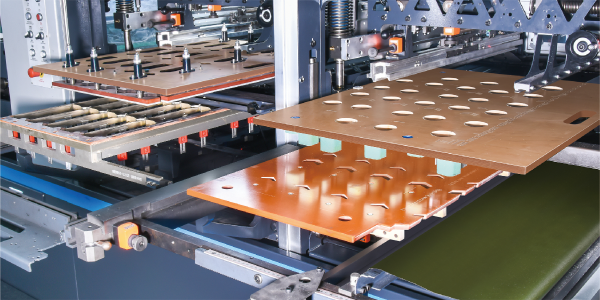

DUOPRESS Automatic High Speed Hot Stamping & Die Cutting Machine With Stripping & Blanking

- Invention patent: the world’s first multi-station die-cutting machine independently controlled by servo motors

- Flexible customization for exact product requirements

- Operate with 50% less labor and space while achieving speeds up to 7,200 sheets/h (40% faster than industry standards)

- Overview

- Technical Parameters

- Related Products

- FAQ

Product Description

Dayuan BHT-series DUOPRESS Automatic High Speed Hot Stamping & Die Cutting Machine With Stripping & Blanking supports one-pass processing for hot foil stamping, die cutting, stripping and blanking, enabling efficient and integrated production. Ideal for paper packaging products with complex, large-area foil stamping and deep embossing effects, this automatic die cutter delivers exceptional value and competitiveness to customers, maximizing productivity while reducing labor costs. It is the premier choice for high-end post-press markets.

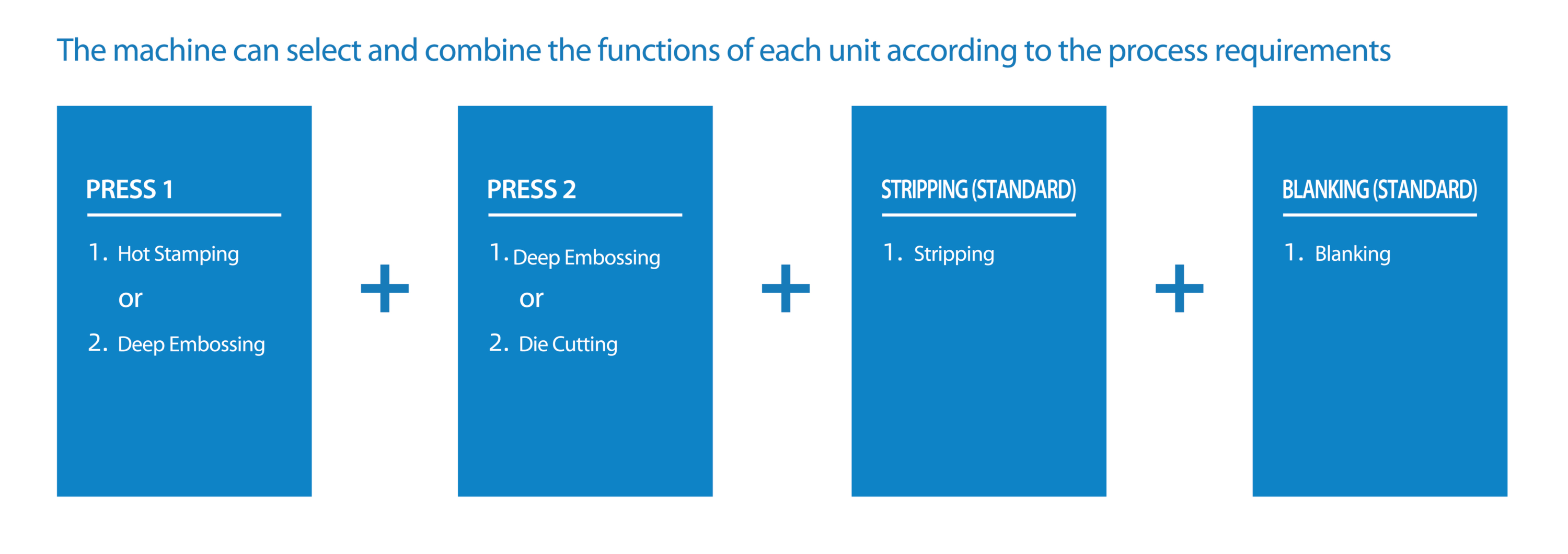

Flexible Customization:

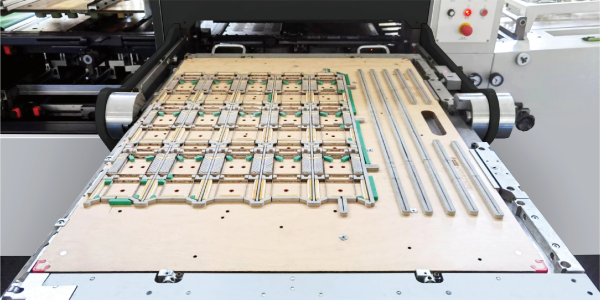

Modular process configuration tailored to product requirements, with each unit independently controlled by servo motors for optional single-unit operation.Features holographic foil stamping, hot foil stamping, deep embossing, die cutting, waste stripping, and blanking to meet diverse production needs and significantly enhance efficiency.

Reliable Performance:

• Maximum speed: 7,200 sheets/hour; maximum pressure: 600 tons.

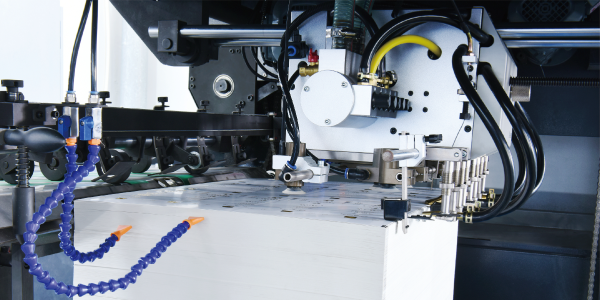

• Equipped with a proprietary foil stamping control system and foil feeding system, it supports both horizontal and vertical stamping to meet premium quality demands, with hot stamping accuracy of ±0.1mm.

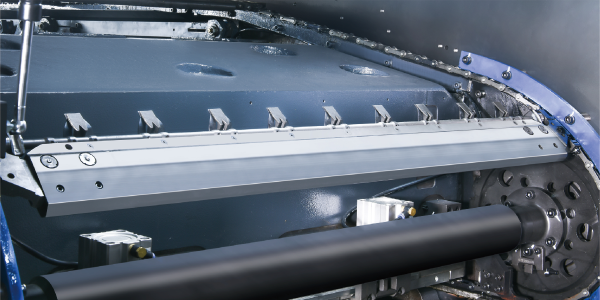

• Lightweight yet durable carbon fiber gripper bars ensure extended machine lifespan.

• Patented gripper bar rear-positioning servo control system guarantees permanent precision of ±0.075mm.

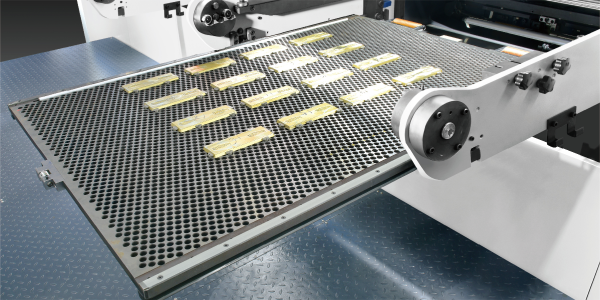

• Automated blanking and batch counting reduce manual intervention, boosting productivity.

Excellent Versatility:

• Supports hot stamping and embossing on various materials

• Ideal for processing complex structure graphics in the printing and packaging industry.

• Enables easy and rapid switching between hot foil stamping and die cutting processes.

Outstanding Cost-Effectiveness:

• Robust cast-iron frame ensures stability.

• User-friendly human-machine interface for intuitive and efficient operation.

• Comprehensive spare parts supply chain for after-sales support.

|

|

|

| Feeder(4 suction and 6 delivery) |

Ultrasonic double sheet detector |

Paper conveying unit |

|

|

|

| Carbon fiber gripper bar |

Micro-adjustable die cutting plate |

Micro-adjustable frame with quick locking device |

|

|

|

| Servo controlled gripper bar positioning device |

Timing belt driven device |

Micro-adjustable honeycomb plate |

|

|

|

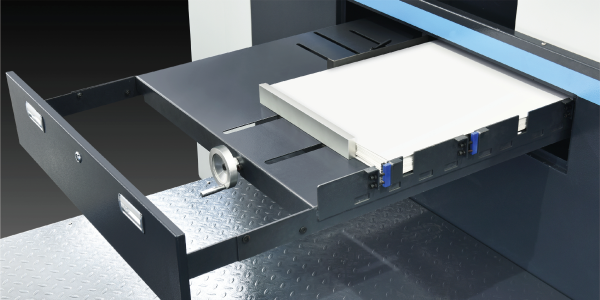

| Advanced plate quick locking device |

Full sheet delivery |

Auto separation sheet insert |

|

|

|

| Non-stopping sampling |

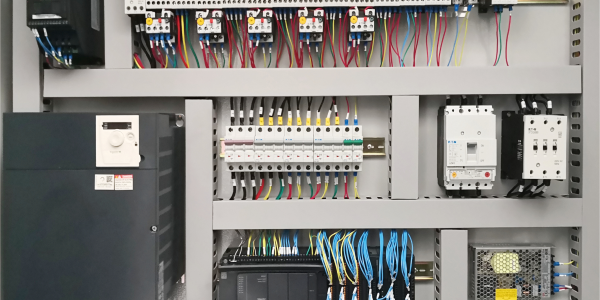

Electrical unit |

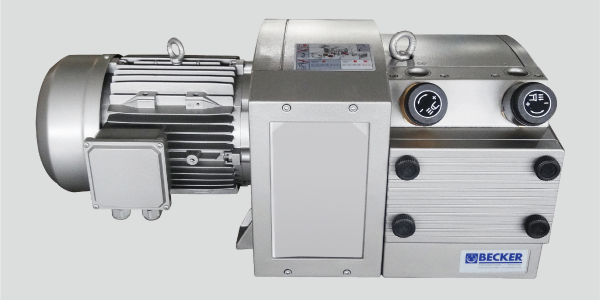

Germany vacuum pump |

|

|

|

| Auto lubrication system |

Main unit cooling/lubrication mechanism |

Technical Parameters

|

Model |

BHT-2S1060TRSCE BHT-2S1060TMSCE |

BHT-2S1060RRSCE BHT-2S1060RMSCE |

|

Maximum Sheet Size |

1060×760mm |

1060×760mm |

|

Minimum Sheet Size |

400×350mm |

400×350mm |

|

Maximum Cutting Size |

1060×745mm |

1060×745mm |

|

Maximum Stamping Size |

1060×740mm |

/ |

|

Maximum Heating Size |

1060×740mm |

1060×740mm |

|

Minimum Gripper Margin |

9-17mm |

9-17mm |

|

Minimum Width of Double Cuts |

5mm |

5mm |

|

Inner Chase Size |

1080×790mm |

1080×790mm |

|

Stock Range |

Cardboard: 80-2000g/m²,0.1-2mm |

Cardboard: 80-2000g/m²,0.1-2mm |

|

Die Cutting Accuracy |

≤±0.075mm |

≤±0.075mm |

|

Stamping Accuracy |

≤±0.1mm |

/ |

|

Heating Accuracy |

≤±0.075mm |

≤±0.075mm |

|

Press 1 Max.Cutting Force |

600T |

600T |

|

Press 2 Max.Cutting Force |

600T / 300T |

600T / 300T |

|

Max.Working Speed |

7200s/h |

7200s/h |

|

Maximum Pile Height at Feeder-Normal Mode |

1800mm |

1800mm |

|

Maximum Pile Height at Feeder-Non-stop Mode |

1520mm |

1520mm |

|

Maximum Pile Height at Delivery |

1580mm |

1580mm |

|

Max.Gold Doil Diameter |

φ250mm Longitudinal,φ200mm Transeversal |

/ |

|

Electric-heated System |

20 Heating zones,40-180℃ Adjustable |

20 Heating zones,40-180℃ Adjustable |

|

Foil Width |

20-1060mm |

/ |

|

Press 1 Foil Advance Shafts |

3 Longitudinal+2 Transversal |

Electric-heated System |

|

Press 2 Foil Advance Shafts |

Electric-heated System+ Stripping+Blanking(TRSCE) |

Electric-heated System+ Stripping+Blanking(RRSCE) |

|

Die Cutting+ Stripping+Blanking(TMSCE) |

Electric-heated System+ Stripping+Blanking(RMSCE) |

|

|

Full Load Wattage |

108KW / 93KW |

96KW / 81KW |

|

Air Requirement |

0.6-0.7MPa,≥1m³/min |

0.6-0.7MPa,≥1m³/min |

|

Net Weight of Machine |

48T / 47T |

46T / 45T |

|

Machine Dimensions(Including Die Preloader)(L×W×H) |

12850×7613×2909mm |

12850×7613×2891mm |