MHK-3S1050TTTC

TRIOPRESS Automatic High Speed Hot Stamping & Die Cutting Machine

- Invention patent: the world’s first three-station die cutting machine

- Flexible customization for exact product requirements

- Operate with 50% less labor and space while achieving speeds up to 6,200 sheets/h (40% faster than industry standards)

- Overview

- Technical Parameters

- Related Products

- FAQ

Product Description

Dayuan MHK-series TRIOPRESS Automatic High Speed Hot Stamping & Die Cutting Machine With Stripping is designed for one-pass processing, integrating foil stamping, die cutting, and stripping into a single, highly efficient operation—perfect for complex foil stamping requirements in premium cigarette packaging, liquor packaging, and other high-end applications. By maximizing productivity and minimizing labor costs, this automatic die cutter delivers exceptional value and enhanced competitiveness, making it the ultimate choice for the high-end post-press market.

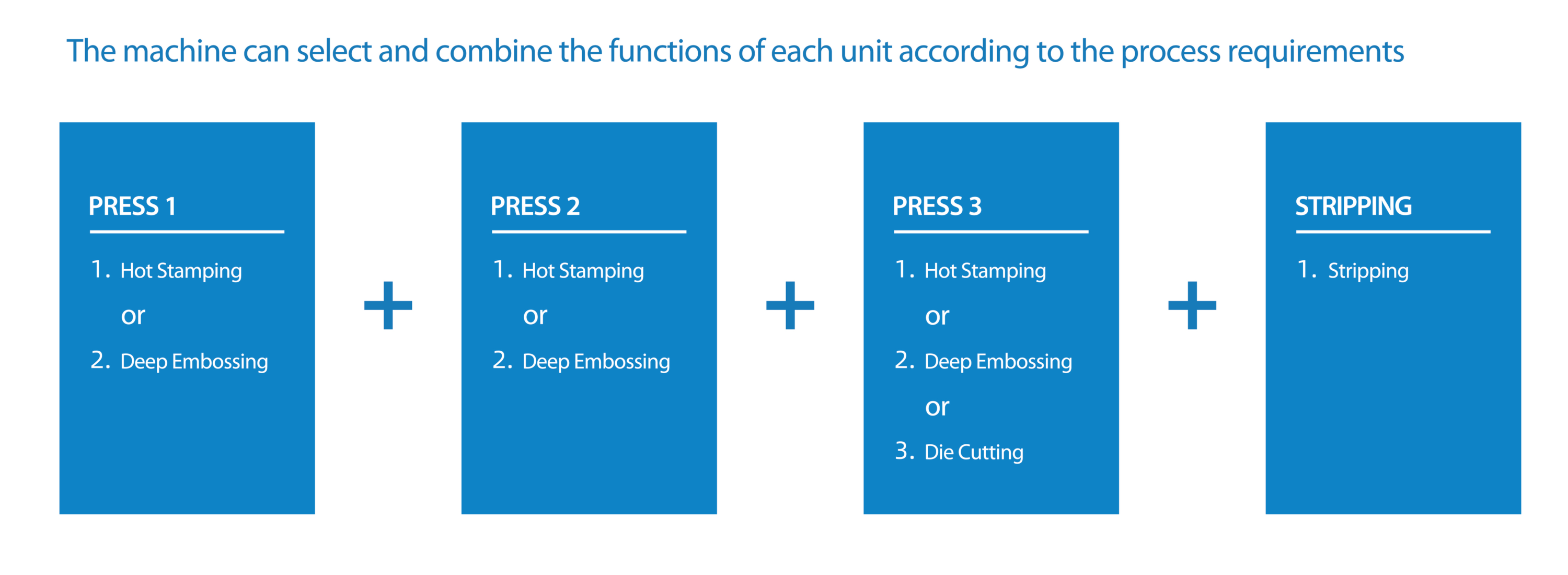

Flexible Customization:

• Modular process configuration tailored to product requirements, with each unit independently controlled by servo motors for optional single-unit operation.

• Features holographic foil stamping, triple foil stamping, deep embossing, die cutting and waste stripping to meet diverse production needs and significantly enhance efficiency.

Reliable Performance:

• Maximum speed: 6,200 sheets/hour; maximum pressure: 600 tons.

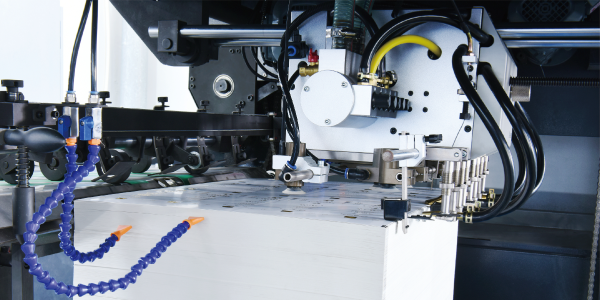

• Equipped with a proprietary foil stamping control system and foil feeding system, it supports both horizontal and vertical stamping to meet premium quality demands, with hot stamping accuracy of ±0.1mm.

• Patented gripper bar rear-positioning servo control system guarantees permanent precision of ±0.075mm.

Excellent Versatility:

• Supports hot stamping and embossing on various materials.

• Ideal for processing complex structure graphics in the printing and packaging industry.

• Enables easy and rapid switching between hot foil stamping and die cutting processes.

Outstanding Cost-Effectiveness:

• Robust cast-iron frame ensures stability.

• Supports quick setup and fast changeover with microadjustment devices.

• User-friendly human-machine interface for intuitive and efficient operation.

• Comprehensive spare parts supply chain for after-sales support.

|

|

|

| Feeder(4 suction and 6 delivery) |

Paper conveying unit |

Front gauge & side gauge |

|

|

|

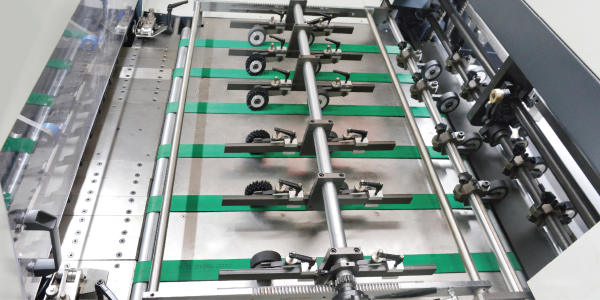

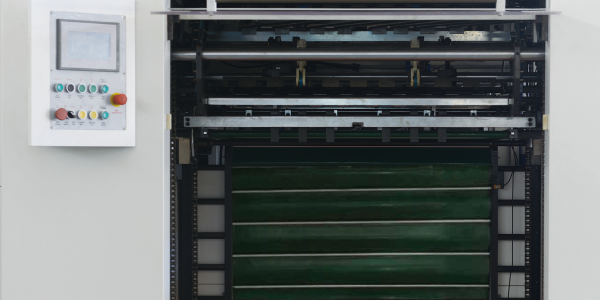

| Timing belt drive, Intermittent mechanism |

Micro-adjustable frame with quick locking device |

Micro-adjustable die cutting plate |

|

|

|

| Servo controlled gripper bar positioning device |

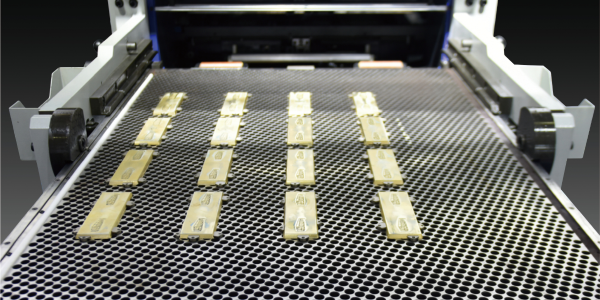

Micro-adjustable honeycomb plate |

Stripping unit |

|

|

|

| Gripper margin stripping device |

Non-stop roll-up curtain type paper delivery device |

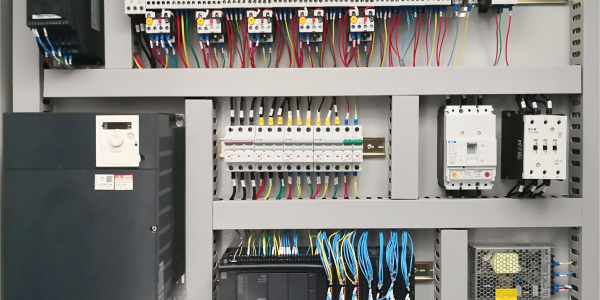

Electrical unit |

|

|

|

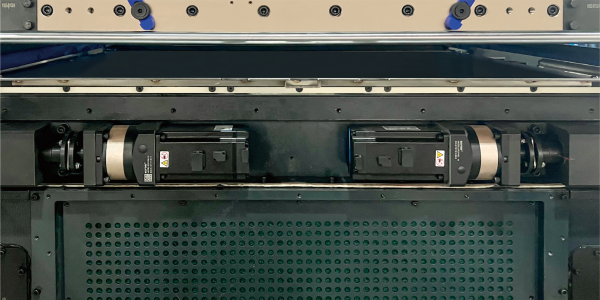

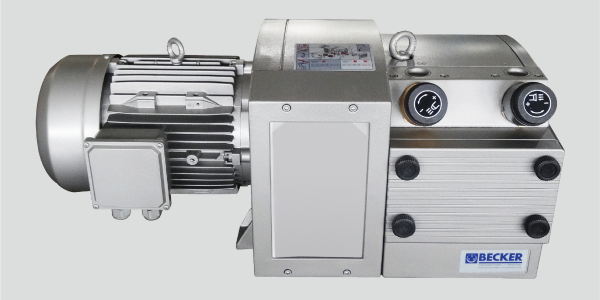

| Germany vacuum pump |

Auto lubrication system |

Main unit cooling/lubrication mechanism |

Technical Parameters

|

Model |

MHK-3S1050TTT MHK-3S1050TTTC |

MHK-3S1050TTRC MHK-3S1050TTMC |

MHK-3S1050TRRC MHK-3S1050TRMC |

MHK-3S1050RRRC MHK-3S1050RRMC |

|

Maximum Sheet Size |

1050×750mm |

1050×750mm |

1050×750mm |

1050×750mm |

|

Minimum Sheet Size |

400×360mm |

400×360mm |

400×360mm |

400×360mm |

|

Maximum Cutting Size |

1040×720mm |

1040×720mm |

1040×720mm |

1040×720mm |

|

Maximum Stamping Size |

1040×720mm |

1040×720mm |

1040×720mm |

/ |

|

Maximum Heating Size |

1040×720mm |

1040×720mm |

1040×720mm |

1040×720mm |

|

Minimum Gripper Margin |

9-17mm |

9-17mm |

9-17mm |

9-17mm |

|

Minimum Width of Cuts |

-- / 10-18mm |

10-18mm |

10-18mm |

10-18mm |

|

Inner Chase Size |

1123×760mm |

1123×760mm |

1123×760mm |

1080×745mm |

|

Stock Range |

Cardboard: 80-2000g/m²,0.1-2mm |

Cardboard: 80-2000g/m²,0.1-2mm |

Cardboard: 80-2000g/m²,0.1-2mm |

Cardboard: 80-2000g/m²,0.1-2mm |

|

Die Cutting Accuracy |

≤±0.075mm |

≤±0.075mm |

≤±0.075mm |

≤±0.075mm |

|

Common stamping accuracy |

≤±0.1mm |

≤±0.1mm |

≤±0.1mm |

/ |

|

Hologram positioning stamping accuracy |

≤±0.1mm |

≤±0.1mm |

≤±0.1mm |

/ |

|

Heating Accuracy |

≤±0.075mm |

≤±0.075mm |

≤±0.075mm |

≤±0.075mm |

|

Press 1 Max.Cutting Force |

600T |

600T |

600T |

600T |

|

Press 2 Max.Cutting Force |

600T |

600T |

600T |

600T |

|

Press 3 Max.Cutting Force |

600T |

600T |

600T |

600T |

|

Max.Working Speed |

6200s/h |

6200s/h |

6200s/h |

6200s/h |

|

Maximum Pile Height at Feeder-Normal Mode |

1600mm |

1600mm |

1600mm |

1600mm |

|

Maximum Pile Height at Delivery |

1400mm |

1400mm |

1400mm |

1400mm |

|

Max.Gold Doil Diameter |

φ250mm Longitudinal,φ200mm Transeversal |

φ250mm Longitudinal,φ200mm Transeversal |

φ250mm Longitudinal,φ200mm Transeversal |

/ |

|

Electric-heated System |

20 Heating zones,40-180℃ Adjustable |

20 Heating zones,40-180℃ Adjustable |

20 Heating zones,40-180℃ Adjustable |

20 Heating zones,40-180℃ Adjustable |

|

Foil Width |

20-1020mm |

20-1020mm |

20-1020mm |

/ |

|

Press 1 Foil Advance Shafts |

3 Longitudinal+2 Transversal |

3 Longitudinal+2 Transversal |

3 Longitudinal+2 Transversal |

Electric-heated System |

|

Press 2 Foil Advance Shafts |

3 Longitudinal+2 Transversal |

3 Longitudinal+2 Transversal |

Electric-heated System |

Electric-heated System |

|

Press 3 Foil Advance Shafts |

3 Longitudinal+2 Transversal |

Electric-heated System+Stripping(TTRC) |

Electric-heated System+Stripping(TRRC) |

Electric-heated System+Stripping(RRRC) |

|

3 Longitudinal+2 Transversal |

Die Cutting+Stripping(TTMC) |

Die Cutting+Stripping(TRMC) |

Die Cutting+Stripping(RRMC) |

|

|

Full Load Wattage |

177KW / 177KW |

165KW / 150KW |

153KW / 138KW |

103KW / 91KW |

|

Air Requirement |

0.6-0.7MPa,≥1m³/min |

0.6-0.7MPa,≥1m³/min |

0.6-0.7MPa,≥1m³/min |

0.6-0.7MPa,≥1m³/min |

|

Net Weight of Machine |

47T / 47T |

46T / 45T |

45T / 45T |

44T / 43T |

|

Machine Dimensions(Including Die Preloader)(L×W×H) |

10915×7424×2658mm |

10915×7424×2658mm |

10915×7424×2658mm |

10915×7424×2658mm |