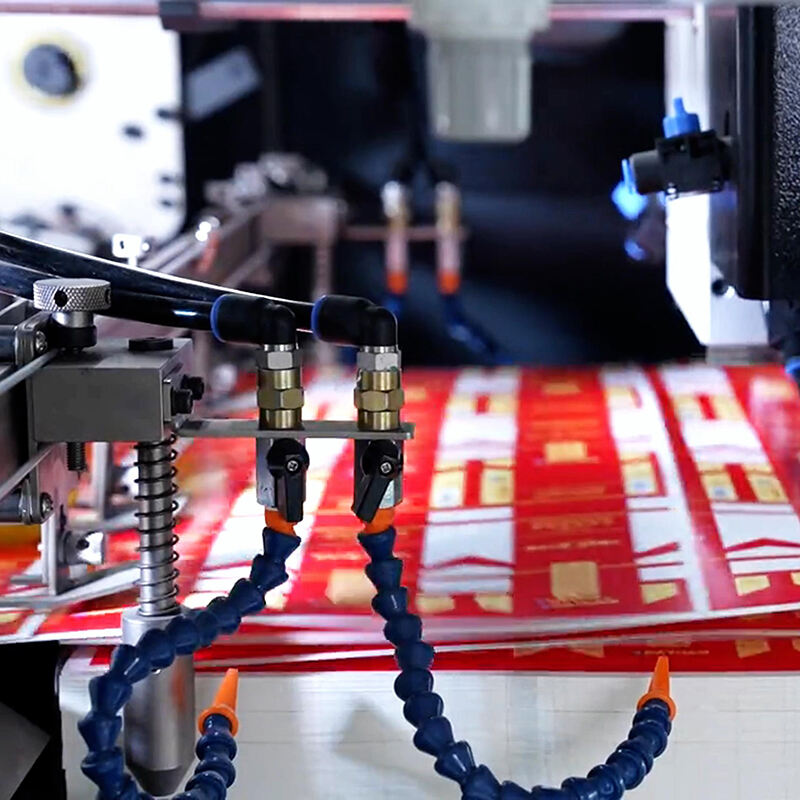

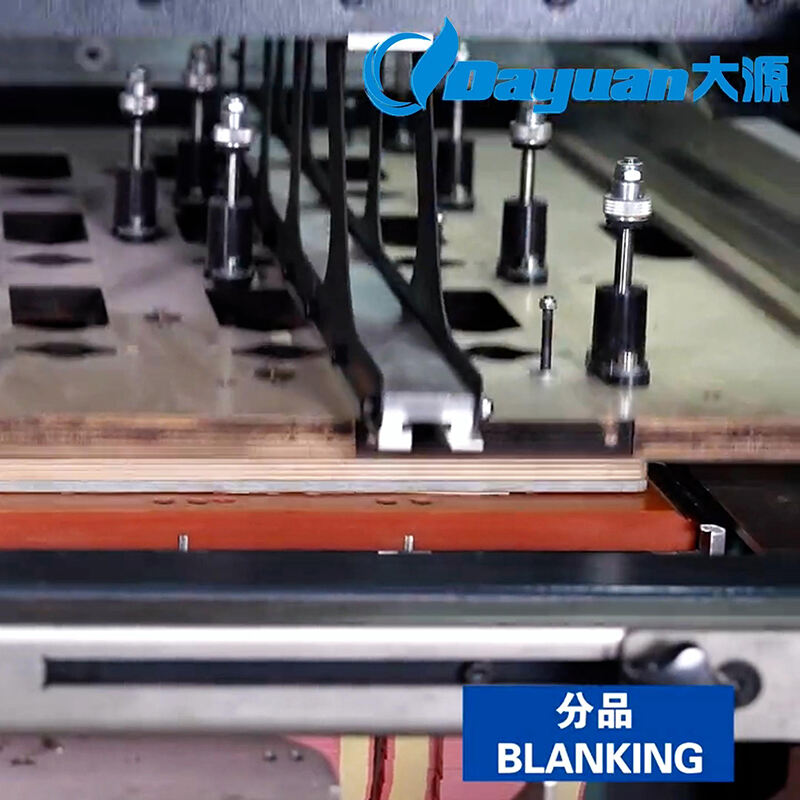

Multi-Material Processing Capability

The machine's versatile multi-material processing capability sets it apart in the industry, offering unprecedented flexibility in production applications. This feature enables seamless processing of diverse materials ranging from standard papers to specialty substrates like leather, plastics, and synthetic materials. The system automatically adjusts its parameters based on material profiles stored in its memory, ensuring optimal processing conditions for each substrate type. Advanced material handling mechanisms prevent common issues like slippage or misalignment, while specially designed feed systems accommodate materials of varying weights and textures. This versatility allows businesses to expand their product offerings without investing in additional equipment. The ability to process multiple material types opens new market opportunities and enables creative applications across various industries, from packaging to promotional materials.