Advanced Technology Integration

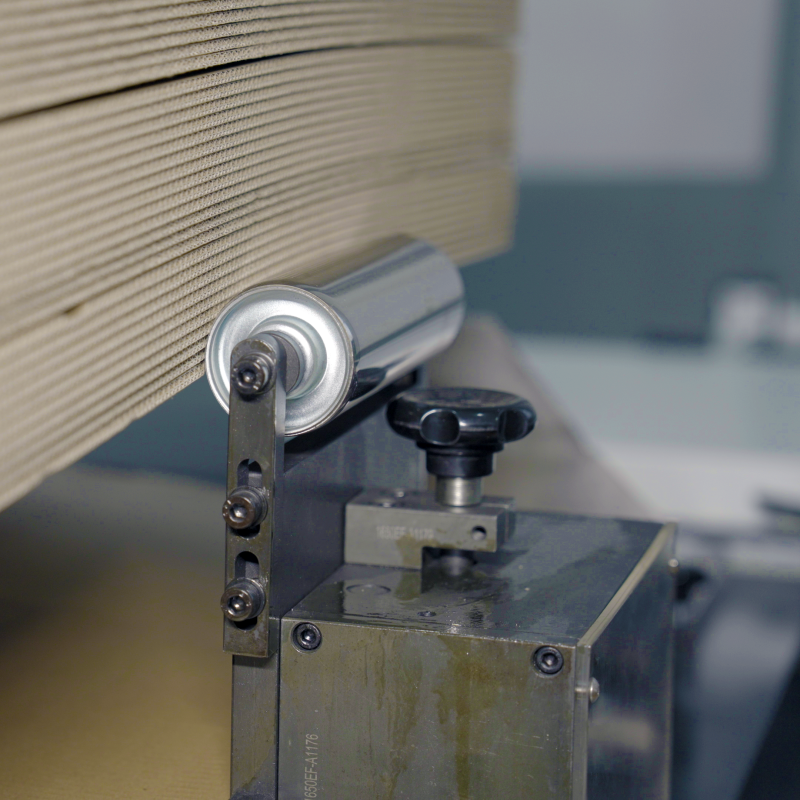

Electric die cutting machine manufacturers excel in seamlessly integrating cutting-edge technology into their products. Their machines feature sophisticated electronic control systems that enable precise adjustments and monitoring of cutting parameters. Advanced sensors and feedback mechanisms ensure consistent cutting quality while automatically adjusting to material variations. The integration of smart connectivity features allows for remote monitoring and diagnostics, enabling predictive maintenance and minimizing downtime. These manufacturers incorporate user-friendly touch screen interfaces that simplify machine operation and programming. The implementation of servo motor technology ensures smooth and accurate movement control, resulting in superior cutting precision. Their machines often include automated material handling systems that streamline production workflows and reduce operator intervention.