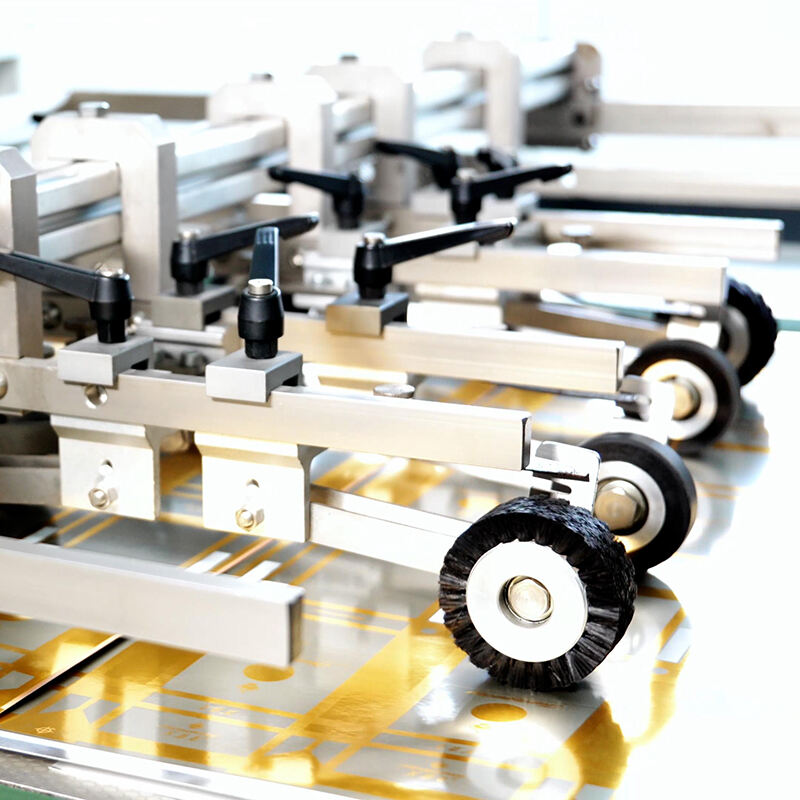

Quick-Change Die System

The innovative quick-change die system revolutionizes production efficiency by dramatically reducing setup and changeover times. This advanced system features a magnetic die mounting mechanism and precision alignment guides that enable operators to switch between different die patterns in minutes rather than hours. The tool-less design eliminates the need for specialized equipment during die changes, while the self-centering mechanism ensures perfect alignment every time. Digital position memory stores frequently used settings, allowing for instant recall of optimal parameters for recurring jobs. This feature significantly reduces downtime between production runs, increases daily output capacity, and provides the flexibility to handle urgent orders or small batch productions efficiently.