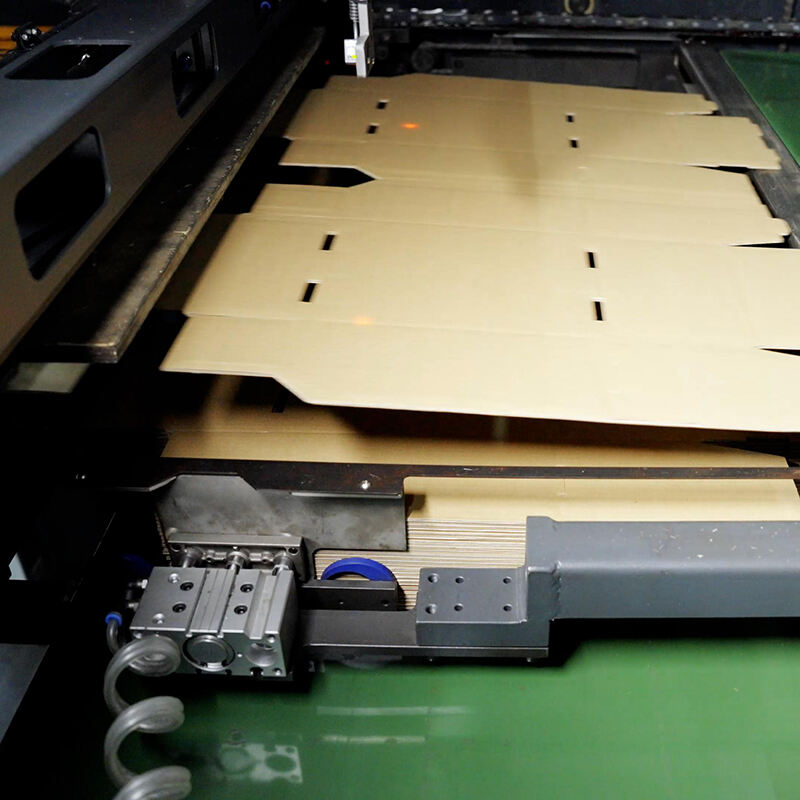

Multi-functional Processing Capabilities

The versatility of the automatic flatbed die cutting machine sets it apart in the manufacturing landscape. Its multi-functional processing capabilities allow it to perform various operations simultaneously, including cutting, creasing, scoring, embossing, and perforating. This eliminates the need for multiple processing steps or machines, significantly reducing production time and costs. The machine can handle a wide range of materials, from lightweight paper to heavy cardboard and plastics, with equal precision. The quick-change tool system allows for rapid transitions between different job specifications, while the modular design enables easy upgrades or modifications to meet changing production requirements. Advanced waste management systems automatically remove and sort waste materials, maintaining a clean working environment and optimizing material usage.