Advanced Cutting Technology

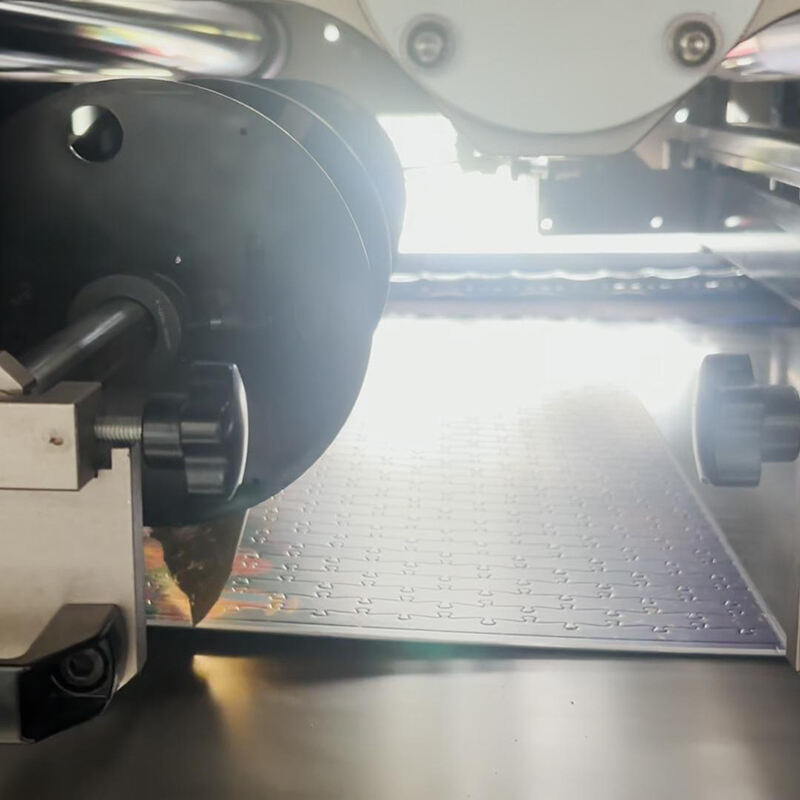

The cutting technology incorporated in the jigsaw puzzle die cutting machine represents the pinnacle of precision manufacturing. The system employs hardened steel dies with microscopically sharp edges, ensuring clean cuts and precise piece shapes every time. The cutting mechanism operates through a combination of hydraulic pressure and mechanical precision, delivering up to 50 tons of cutting force while maintaining exceptional accuracy. The dies are manufactured using advanced CNC technology, guaranteeing exact specifications and perfect symmetry in puzzle piece patterns. This cutting system includes automatic depth adjustment capabilities, allowing for consistent cutting depth regardless of material variations. The technology also features automatic pressure compensation, ensuring uniform cutting quality across the entire puzzle surface.