Advanced Technology Integration

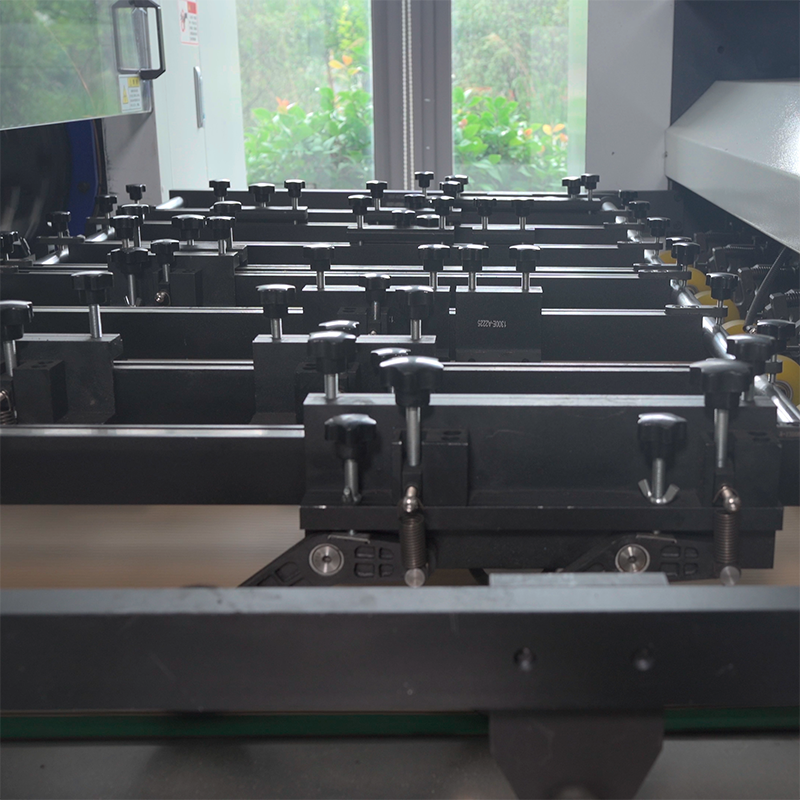

Modern card die cutter manufacturers seamlessly integrate cutting-edge technology into their equipment, revolutionizing the card production process. The incorporation of precision servo motors and advanced motion control systems enables extremely accurate cutting positions, with tolerances as tight as 0.1mm. Digital control interfaces feature intuitive touchscreen operations, allowing operators to easily program and monitor cutting parameters. The systems employ sophisticated sensor arrays that continuously monitor blade condition, material positioning, and cut quality, automatically adjusting parameters to maintain optimal performance. This technological integration extends to connectivity features, enabling remote diagnostics and predictive maintenance capabilities that minimize unexpected downtime and enhance overall equipment effectiveness.