Understanding Industrial Die Cutting Excellence

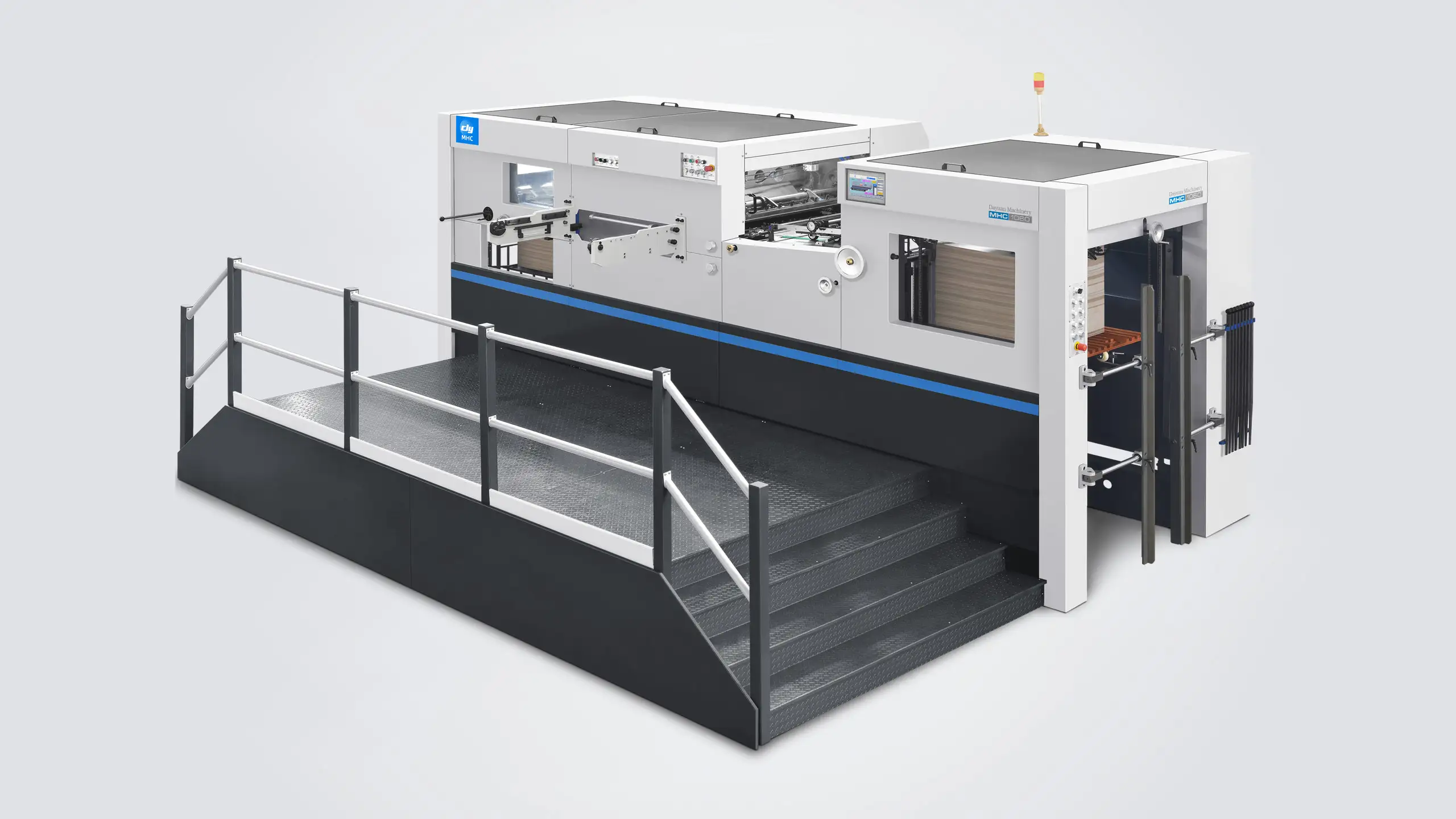

The world of industrial die cutting has evolved significantly, with flatbed die cutters emerging as essential tools for businesses handling thick materials. These robust machines combine precision, power, and versatility to deliver clean cuts across various demanding substrates. Whether you're in packaging, signage, or manufacturing, choosing the right flatbed die cutter can dramatically impact your production efficiency and output quality.

Today's market offers sophisticated flatbed die cutters equipped with advanced features like digital controls, automated feed systems, and enhanced pressure distribution mechanisms. These innovations have revolutionized how businesses approach thick material processing, enabling faster turnaround times and reduced material waste.

Essential Features of Premium Die Cutting Systems

Advanced Cutting Mechanisms

Modern flatbed die cutters incorporate state-of-the-art cutting technologies that ensure precise results even with the most challenging materials. The cutting mechanism's design plays a crucial role in maintaining consistency across large production runs. High-end models feature reinforced platens and specialized bearings that minimize vibration, resulting in cleaner cuts and extended die life.

The pressure distribution system in premium flatbed die cutters ensures uniform force application across the entire cutting surface. This uniformity is particularly important when processing thick materials like corrugated boards. Advanced models often include pressure adjustment controls that operators can fine-tune based on material specifications.

Material Handling Capabilities

Superior feeding systems distinguish top-tier flatbed die cutters from basic models. Automated sheet feeders with air separation technology prevent material jamming and ensure smooth operation. The best machines feature adjustable feed tables that accommodate various material sizes and thicknesses without compromising processing speed.

Registration accuracy is another critical aspect of material handling. Leading flatbed die cutters employ optical registration systems that automatically align materials for precise cutting. This technology is especially valuable when working with pre-printed materials or when multiple cutting passes are required.

Performance Comparison of Leading Models

Cutting Speed and Efficiency

The most advanced flatbed die cutters achieve impressive production speeds without sacrificing accuracy. High-performance models can process up to 3,000 sheets per hour, depending on material type and complexity of the die pattern. These machines maintain consistent cutting quality even during extended production runs, minimizing downtime and maximizing output.

Energy efficiency has become increasingly important in modern flatbed die cutters. New models incorporate energy-saving features like standby modes and optimized motor systems that reduce power consumption without compromising performance. This attention to efficiency helps businesses maintain sustainable operations while controlling operating costs.

Durability and Maintenance Requirements

Premium flatbed die cutters are built with industrial-grade components designed for continuous operation. The frame construction typically features heavy-duty steel that resists flexing and maintains alignment even under high pressure loads. This robust construction translates to longer service life and reduced maintenance requirements.

Preventive maintenance features in modern machines include automated lubrication systems and wear indicators that alert operators to potential issues before they impact production. The best manufacturers also provide comprehensive service support and readily available replacement parts to minimize any potential downtime.

Integration and Workflow Optimization

Digital Interface and Controls

Contemporary flatbed die cutters feature intuitive touchscreen interfaces that simplify operation and reduce training requirements. These digital controls allow operators to store and recall job settings, streamlining setup for repeat orders. Advanced systems also provide real-time performance monitoring and production data analysis.

Network connectivity enables integration with existing workflow management systems, allowing for automated job queuing and production reporting. This connectivity also facilitates remote diagnostics and software updates, ensuring the machine remains current with the latest operational improvements.

Automation and Industry 4.0 Compatibility

Leading flatbed die cutters support automation features that align with Industry 4.0 principles. These machines can be integrated into automated production lines, with capabilities for robotic material handling and automatic waste removal. Such integration significantly reduces labor requirements while increasing throughput.

Data collection and analysis capabilities help operators optimize production parameters and identify opportunities for efficiency improvements. Modern flatbed die cutters can track metrics like cutting force, speed, and material usage, providing valuable insights for process optimization.

Frequently Asked Questions

What maximum material thickness can industrial flatbed die cutters handle?

Industrial flatbed die cutters can typically process materials up to 28mm thick, depending on the specific model and material composition. However, it's essential to consult the manufacturer's specifications as cutting capacity varies between machines and material types.

How often should die cutting tools be replaced?

Die cutting tools should be inspected regularly and typically require replacement after 500,000 to 1 million cuts, depending on material thickness and hardness. Monitoring cut quality and maintaining proper machine settings can help extend tool life significantly.

What safety features should I look for in a flatbed die cutter?

Essential safety features include emergency stop buttons, light curtains or safety guards around moving parts, two-hand operation controls, and automatic shut-off systems. Modern machines should also comply with current safety standards and include proper lockout/tagout capabilities.