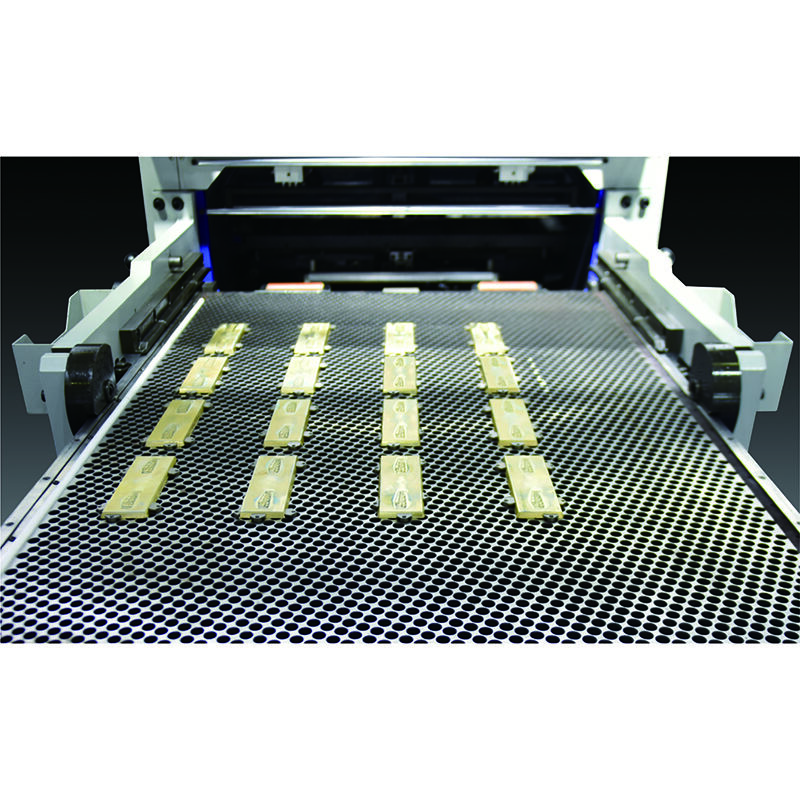

Precision Pressure Distribution Technology

The pressure distribution technology in modern hot foil stamping machines represents a significant engineering achievement that ensures uniform force application across the entire stamping area. This system utilizes hydraulic or pneumatic mechanisms coupled with electronic sensors to maintain consistent pressure levels during operation. The technology allows for precise adjustment of pressure settings to accommodate different substrate thicknesses and foil types, ensuring optimal results across varied materials. Advanced pressure monitoring systems provide real-time feedback, allowing operators to make immediate adjustments when necessary. The even distribution of pressure prevents common issues such as incomplete transfer or excessive depth, resulting in consistent, high-quality impressions across large production runs.