Advanced Technology Integration

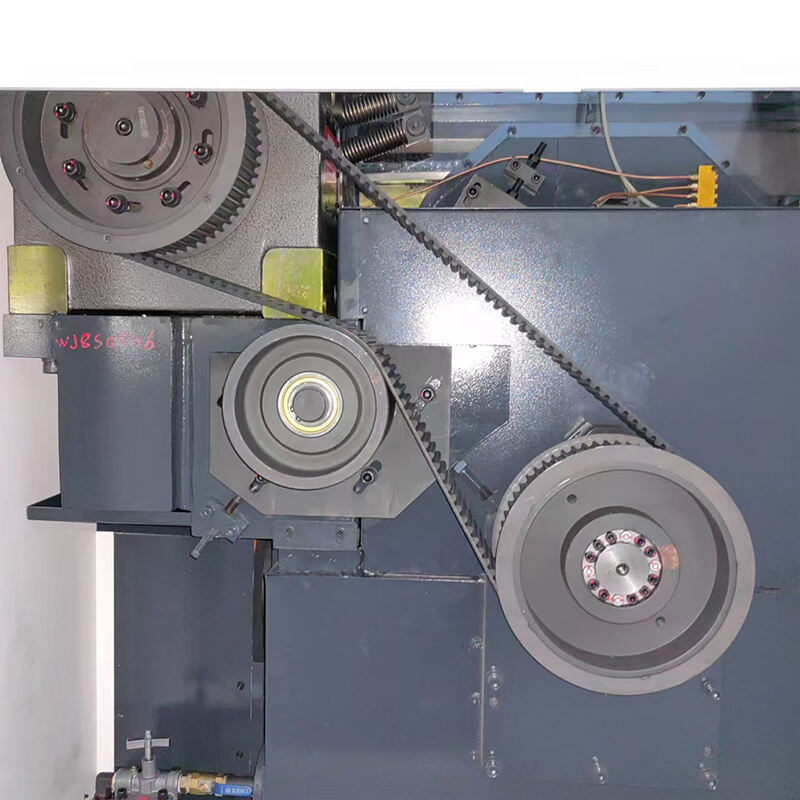

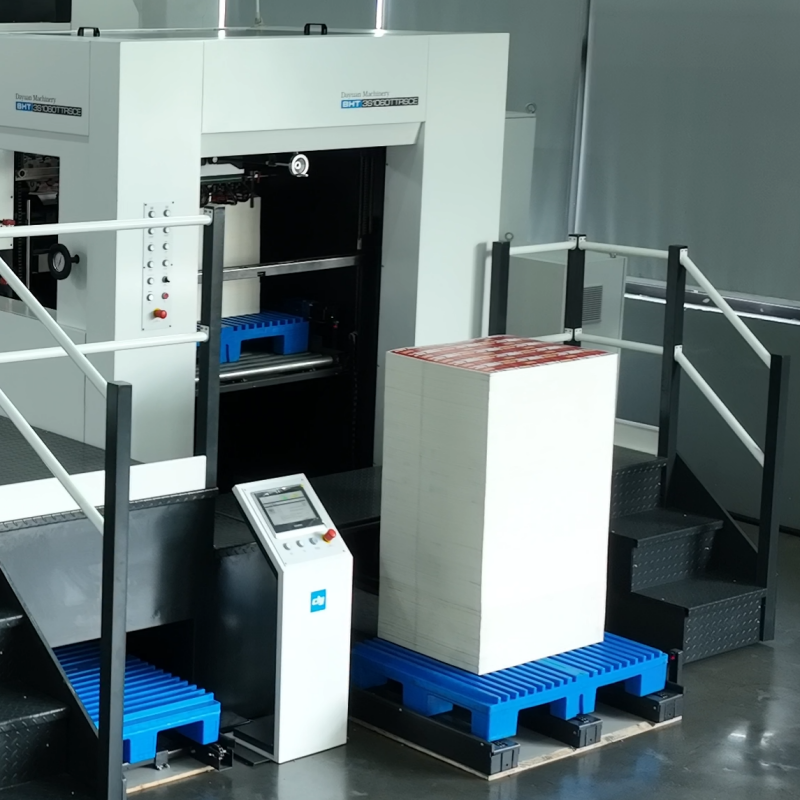

Modern automatic hot foil stamping machine manufacturers excel in incorporating cutting-edge technology into their equipment. Their machines feature sophisticated microprocessor-controlled systems that ensure precise coordination of temperature, pressure, and timing parameters. This integration allows for real-time monitoring and adjustment of stamping conditions, resulting in consistently high-quality output. The manufacturers implement advanced servo motor technology for accurate positioning and movement control, enabling precise foil placement and reducing material waste. Additionally, they incorporate IoT capabilities for remote monitoring and predictive maintenance, helping operators maintain optimal performance and prevent unexpected downtime. These technological advancements make their machines more efficient, reliable, and user-friendly while providing valuable production data for process optimization.