Multi-tool Functionality

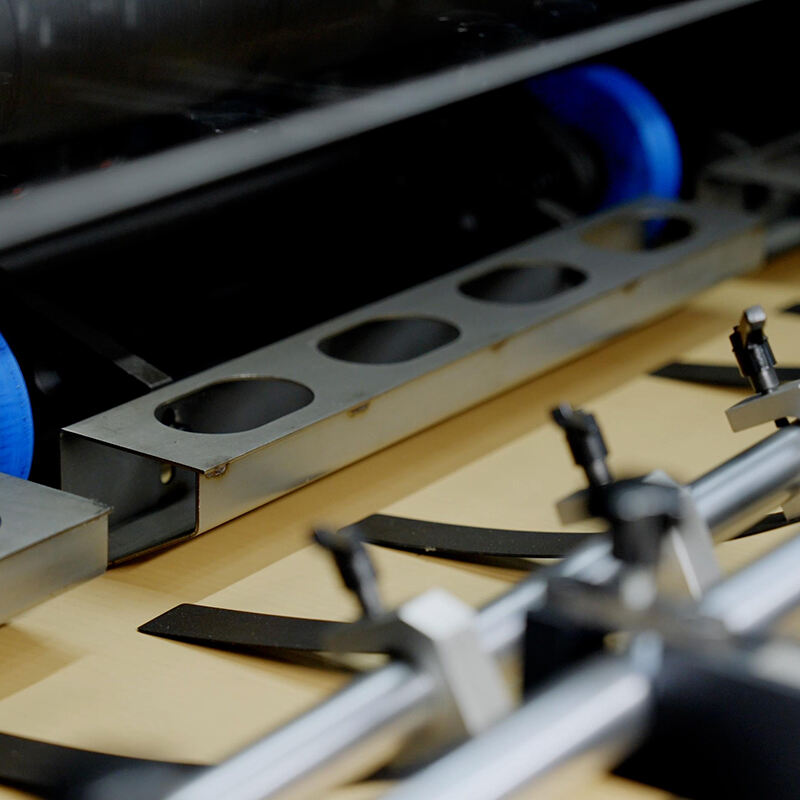

The machines innovative multi-tool capability transforms it into a comprehensive production center. The automatic tool changing system accommodates various cutting implements, from rotary and tangential knives to creasing wheels and routing bits. This versatility enables the processing of diverse materials and the creation of different finishes within a single setup, eliminating the need for multiple specialized machines. The tool recognition system automatically adjusts cutting parameters based on the selected tool and material, ensuring optimal performance and extending tool life. The precision-engineered tool holders maintain consistent pressure and angle throughout operation, resulting in clean, professional cuts every time.