Comprehensive Quality Assurance System

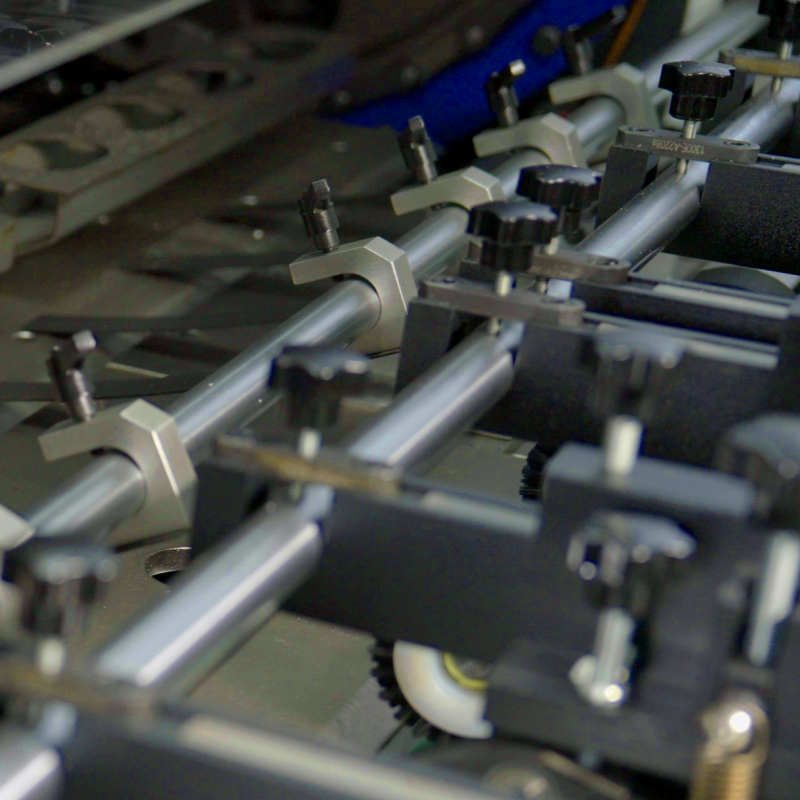

The factory implements a rigorous quality assurance system that encompasses every aspect of production. This system begins with incoming material inspection and continues through component manufacturing, assembly, and final testing. Each machine undergoes extensive testing procedures, including operational testing under various conditions, durability testing, and performance verification. The quality control team utilizes advanced inspection equipment, including digital measuring tools and automated testing stations, to ensure compliance with specifications. Statistical process control methods are employed to monitor production trends and identify potential issues before they affect product quality. The factory maintains detailed documentation of all quality control processes and test results, ensuring traceability and continuous improvement.