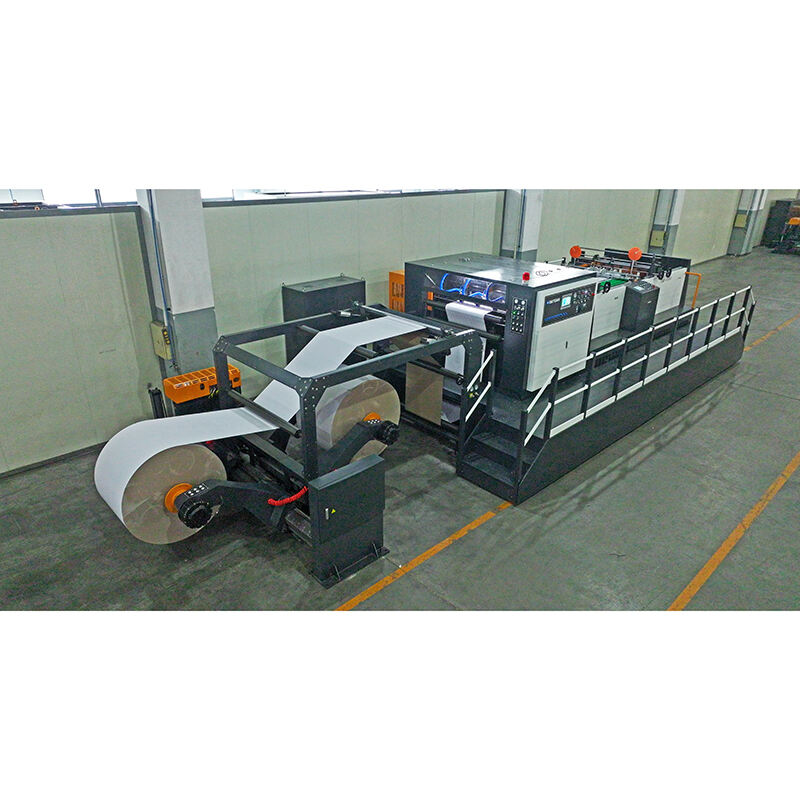

Automated Production Management

The automated production management system integrated into modern roll to sheet cutting machines revolutionizes workflow efficiency. This comprehensive system includes advanced features such as automatic sheet counting, defect detection, and intelligent stacking mechanisms. The management interface allows operators to program multiple job parameters, including sheet dimensions, cut quantities, and production speeds, enabling seamless transitions between different production runs. Real-time monitoring capabilities provide instant feedback on production metrics, allowing for immediate adjustments to optimize performance. The system also maintains detailed production logs, enabling better tracking of material usage, productivity rates, and quality metrics. This level of automation not only increases operational efficiency but also provides valuable data for process improvement and quality control.