Precision Control and Accuracy

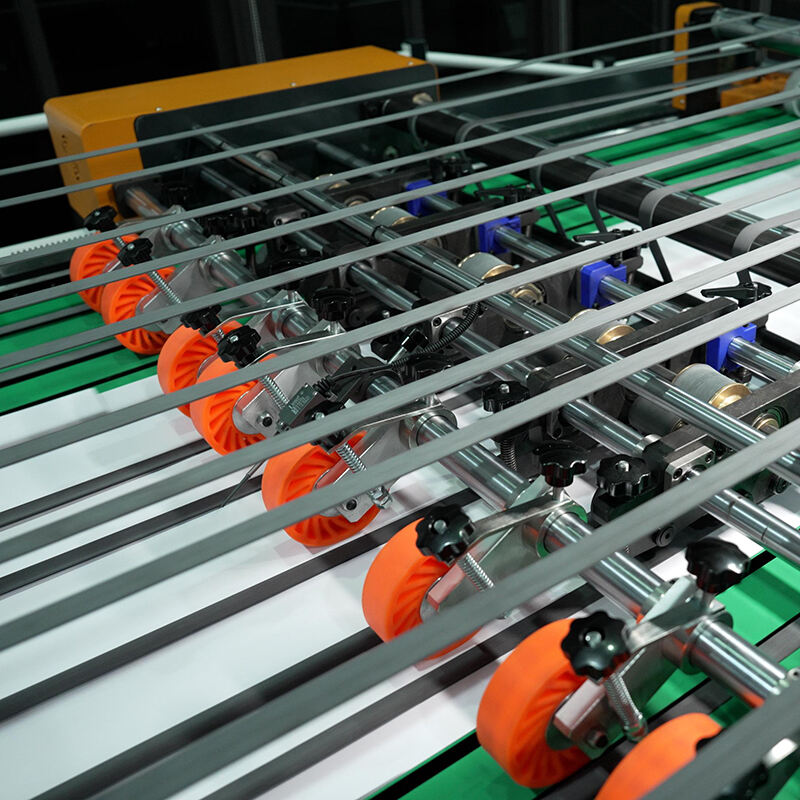

The roll to sheet cutter machine excels in delivering unprecedented precision through its advanced control systems. At the heart of this capability is a sophisticated servo motor system that provides exact control over material feed rates and cutting operations. The machine incorporates high-resolution encoders that continuously monitor position and speed, ensuring cutting accuracy down to fractions of a millimeter. This precision is maintained through an intelligent feedback system that automatically adjusts for any variations in material properties or operating conditions. The control interface allows operators to input exact specifications for sheet length, width, and quantity, with the system automatically maintaining these parameters throughout the production run. Advanced tension control mechanisms ensure consistent material handling, preventing distortion or misalignment during the cutting process. This level of precision not only guarantees product quality but also minimizes material waste and reduces the need for quality control interventions.