Integrated Quality Assurance System

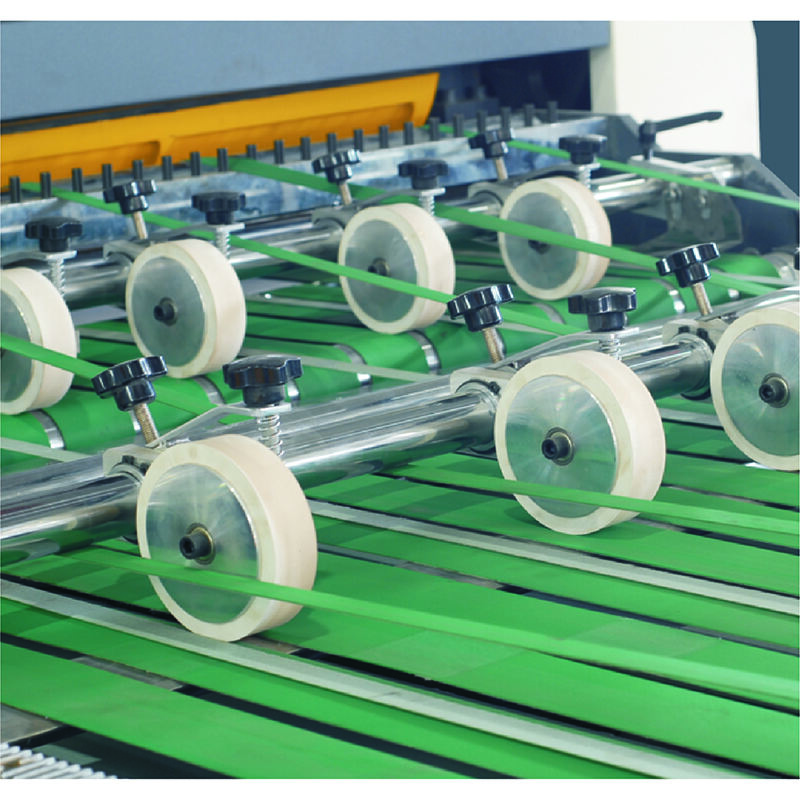

The integrated quality assurance system represents a cornerstone feature of modern industrial slitters, incorporating multiple layers of monitoring and control to ensure consistent product quality. This comprehensive system includes real-time defect detection capabilities that can identify and flag issues such as irregular cuts, material imperfections, or tension inconsistencies during the slitting process. High-speed cameras and sensors continuously monitor the cutting operation, while sophisticated software analyzes the data to maintain quality standards. The system automatically generates detailed quality reports for each production run, providing valuable documentation for quality control and compliance purposes. Additionally, the integrated system can predict potential issues before they occur, allowing for preventive maintenance and reducing unplanned downtime.