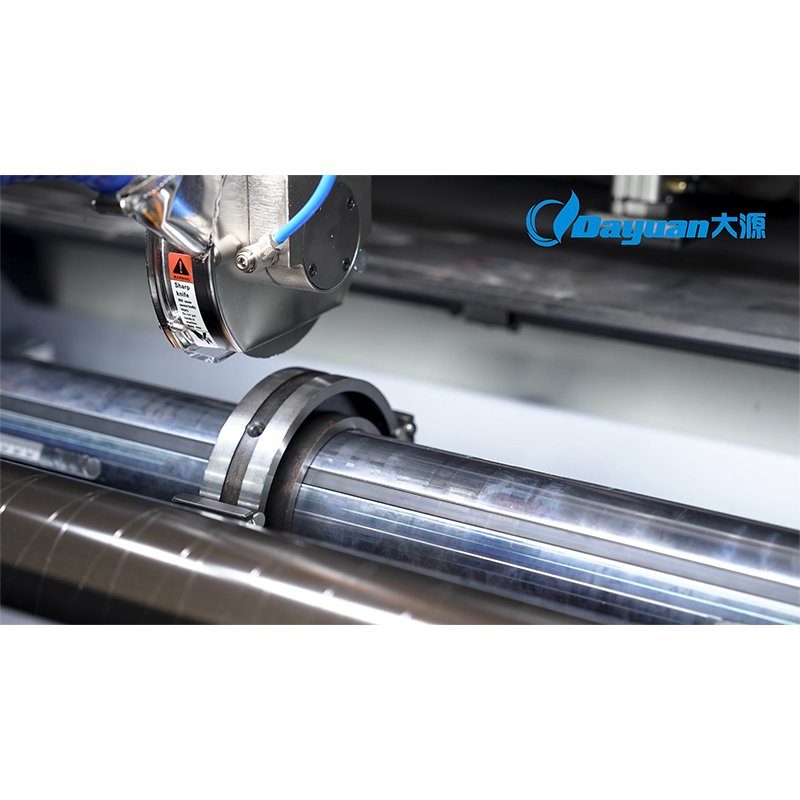

Advanced Tension Control System

The advanced tension control system represents a cornerstone feature of modern paper slitting machines, delivering unprecedented precision and reliability in paper processing operations. This sophisticated system employs multiple tension zones with independent control, ensuring optimal web tension from unwinding through to rewinding. Load cells and dancers continuously monitor and adjust tension levels in real-time, compensating for variations in material properties and roll diameter changes. This precise control prevents common issues such as wrinkles, telescoping, and irregular edges that can compromise product quality. The system's ability to maintain consistent tension across different paper grades and thicknesses enhances operational flexibility while minimizing waste and maximizing production efficiency.