Integrated Quality Control Features

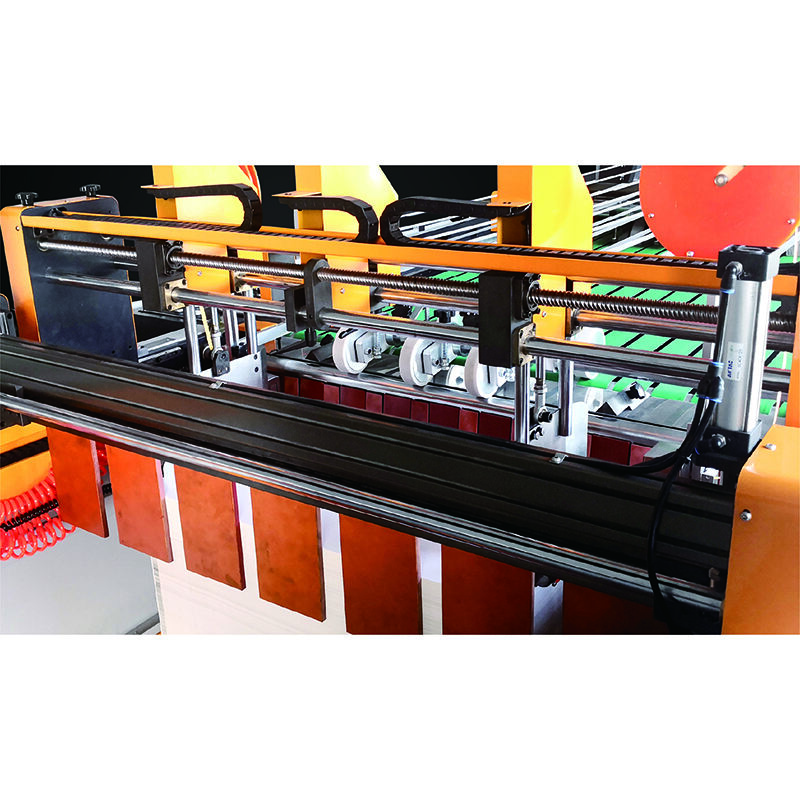

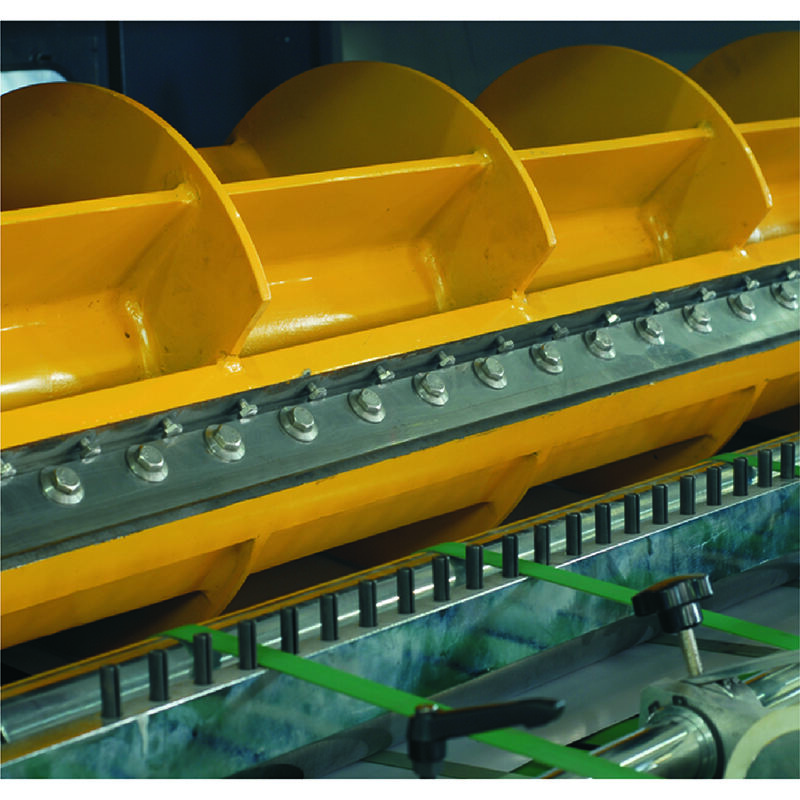

The automatic slitter incorporates comprehensive quality control features that ensure consistent production excellence. Advanced inspection systems continuously monitor cut quality and material alignment, automatically adjusting parameters to maintain optimal performance. The machine's integrated defect detection capability identifies and marks potential quality issues, allowing for immediate corrective action. Real-time data collection and analysis provide valuable insights into production efficiency and product quality trends. The system's ability to maintain detailed production records supports quality assurance requirements and facilitates process optimization. Additionally, automated width verification systems ensure that all cut materials meet specified dimensions, while tension monitoring prevents material stretching or damage during processing.