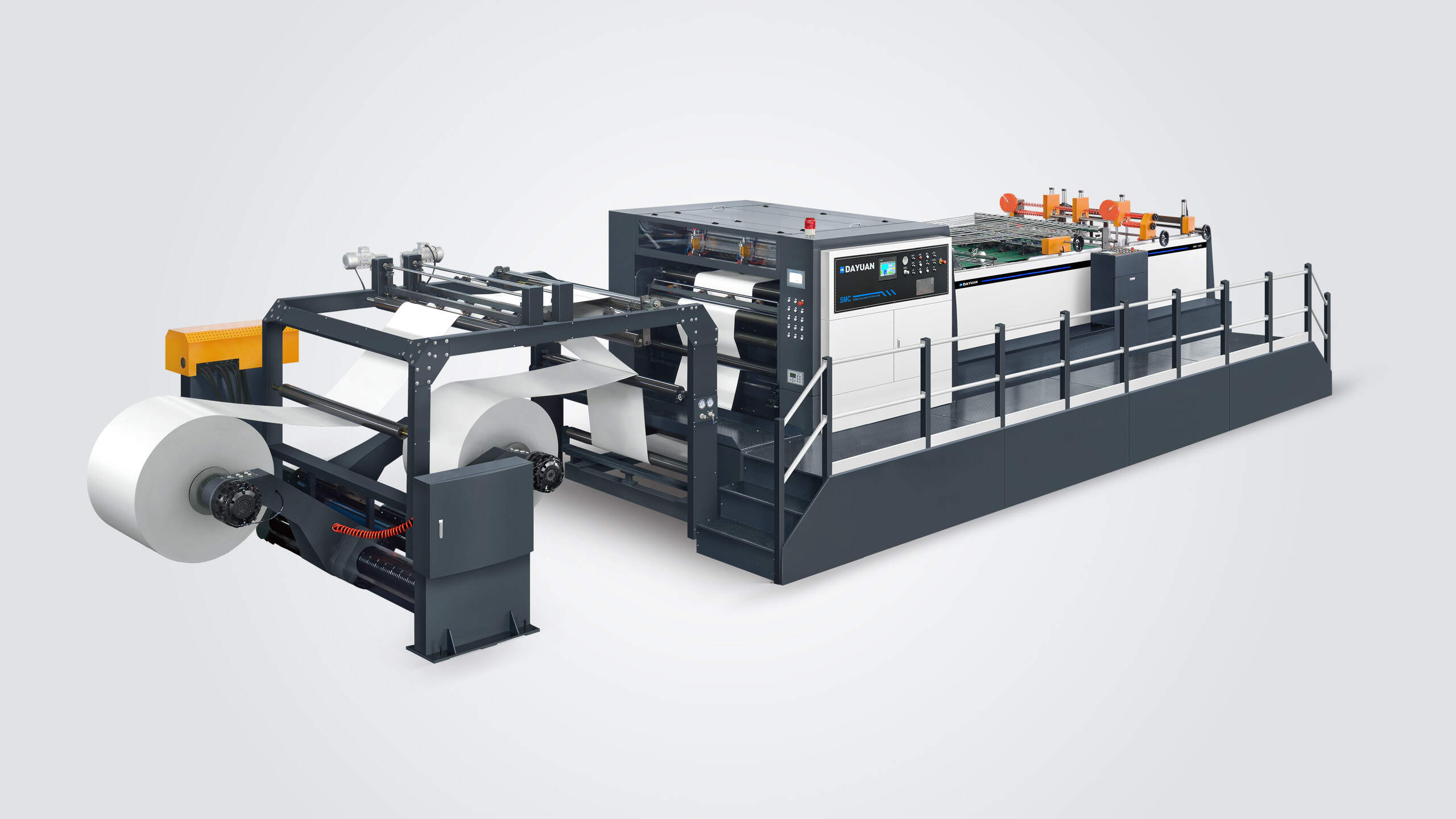

MHK-2S1050TTC

DUOPRESS Automatic High Speed Double Foil Stamping And Die Cutting Machine With Stripping

- Overview

- Main Technical Parameters

- Related Products

Product Description

MHK-2S920TT

The following processes can be realized in one paper pass:

1.Hot Stamping + Hot Stamping

2.Hot Stamping + Die Cutting

3.Deep Embossing + Die Cutting

4.Hot Stamping + Deep Embossing

MHK-2S920TRC:

The following processes can be realized in one paper pass:

1.Hot Stamping + Die Cutting + Stripping

2.Deep Embossing + Die Cutting + Stripping

3.Hot Stamping + Deep Embossing

MHK-2S920TMC:

The following processes can be realized in one paper pass:

1.Hot Stamping + Die Cutting + Stripping

2.Deep Embossing + Die Cutting + Stripping

MHK-2S920RRC:

The following processes can be realized in one paper pass:

1.Deep Embossing + Die Cutting + Stripping

2.Deep Embossing + Deep Embossing

MHK-2S920RMC:

The following processes can be realized in one paper pass:

1. Deep Embossing + Die Cutting + Stripping

|

|

|

| Feeder | Conveying unit | Front gauge & side gauge |

|

|

|

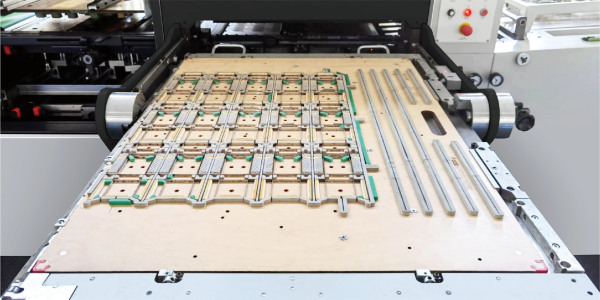

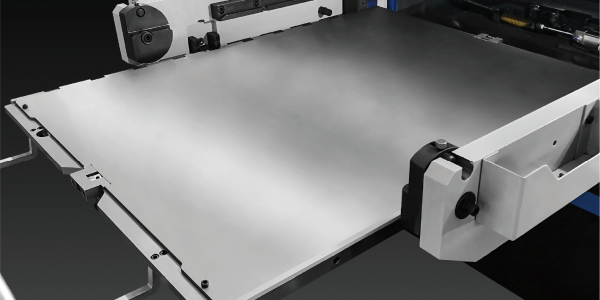

| Timing belt driven device | Mould quick locking device | Cutting plate micro adjustment device |

|

|

|

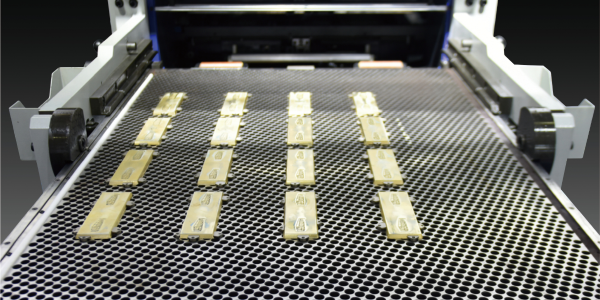

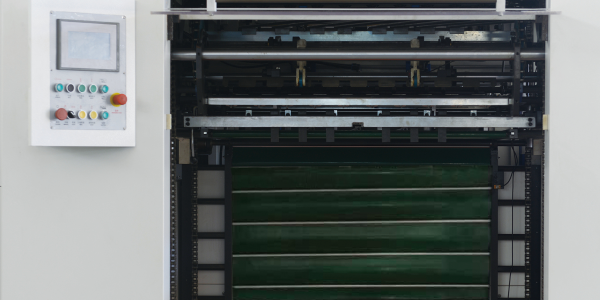

| Servo controlled gripper bar positioning device | Fine-tuned honeycomb plate | Three layer stripping section |

|

|

|

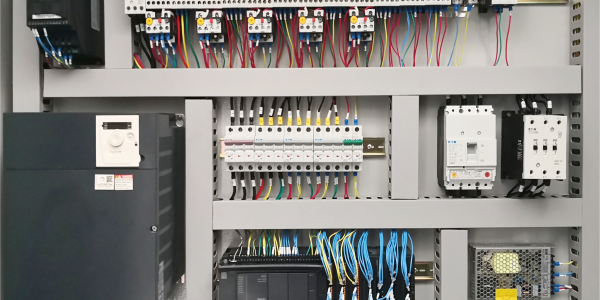

| Gripper waste removal device | Auto non-stop collection device | Electrical unit |

|

|

|

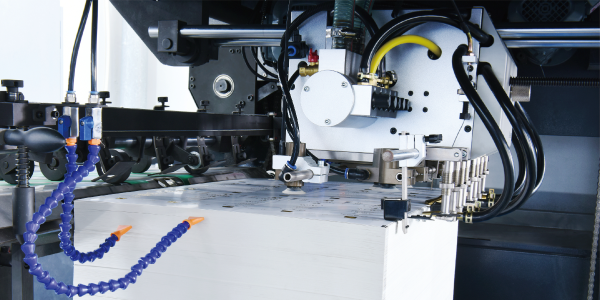

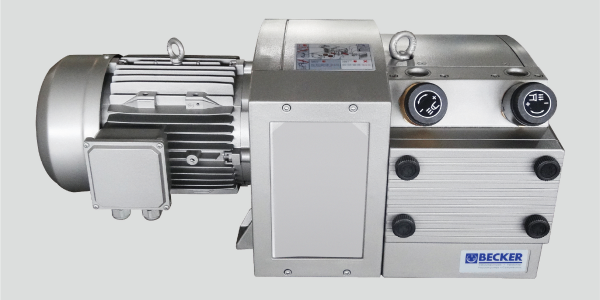

| Germany vacuum pump | Concentrate lubrication | Cooling and lubrication mechanism of the main engine |

Main Technical Parameters

|

Model |

MHK-2S920TT |

MHK-2S920TRC/2S920TMC |

MHK-2S920RRC/2S920RMC |

|

Maximum Sheet Size |

920×650 |

920×650mm |

920×650mm |

|

Minimum Sheet Size |

360×320mm |

360×320mm |

360×320mm |

|

Maximum Cutting Size |

920×630mm |

920×630mm |

920×630mm |

|

Maximum Stamping Size |

900×600mm |

900×600mm |

/ |

|

Maximum Heating Size |

900×600mm |

900×600mm |

900×600mm |

|

Minimum Gripper Margin |

9-17mm |

9-17mm |

9-17mm |

|

Minimum Width of Cuts |

/ |

10-18mm |

10-18mm |

|

Inner Chase Size |

1008×670mm |

1008×670mm |

1008×670mm |

|

Stock Range |

Cardboard: 80-2000g/m²,0.1-2mm |

Cardboard: 80-2000g/m²,0.1-2mm |

Cardboard: 80-2000g/m²,0.1-2mm |

|

Die Cutting Accuracy |

≤±0.075mm |

≤±0.075mm |

≤±0.075mm |

|

Common Stamping Accuracy |

≤±0.075mm |

≤±0.075mm |

/ |

|

Hologram positioning stamping accuracy |

≤±0.075mm |

≤±0.075mm |

/ |

|

Heating Accuracy |

≤±0.075mm |

≤±0.075mm |

≤±0.075mm |

|

Press 1 Max.die Cutting Force |

600T |

600T |

600T |

|

Press 2 Max.die Cutting Force |

600T |

600T |

600T |

|

Max.working Speed |

7200s/h |

7200s/h |

7200s/h |

|

Maximum Pile Height at Feeder-Normal Mode |

1500mm |

1500mm |

1500mm |

|

Maximum Pile Height at Delivery |

1300mm |

1300mm |

1300mm |

|

Max.gold Doil Diameter |

φ250mm Longitudinal,φ200mm Transeversal |

φ250mm Longitudinal,φ200mm Transeversal |

/ |

|

Electric-heated System |

20 Heating zones,40-180℃ Adjustable |

20 Heating zones,40-180℃ Adjustable |

20 Heating zones,40-180℃ Adjustable |

|

Foil Width |

20-900mm |

20-900mm |

/ |

|

Press 1 Foil Advance Shafts |

3 Longitudinal+2 Transversal(opt.) |

3 Longitudinal+2 Transversal(opt.) |

Electric-heated System |

|

Press 2 Foil Advance Shafts |

3 Longitudinal+2 Transversal(opt.) |

Electric-heated System+Stripping(TRC) |

Electric-heated System+Stripping(RRC) |

|

Die Cutting+Stripping(TMC) |

Die Cutting+Stripping(RMC) |

||

|

Full Load Wattage |

77KW / 77KW |

65KW / 52KW |

56KW / 42KW |

|

Air Requirement |

0.6-0.7MPa,≥1m³/min |

0.6-0.7MPa,≥1m³/min |

0.6-0.7MPa,≥1m³/min |

|

Net Weight of Machine |

28T |

27T |

26T |

|

Machine Dimensions(Including Die Preloader)(L×W×H) |

7615×6960×2658mm |

7615×6960×2658mm |

7615×6960×2658mm |