Comprehensive Safety and Quality Assurance

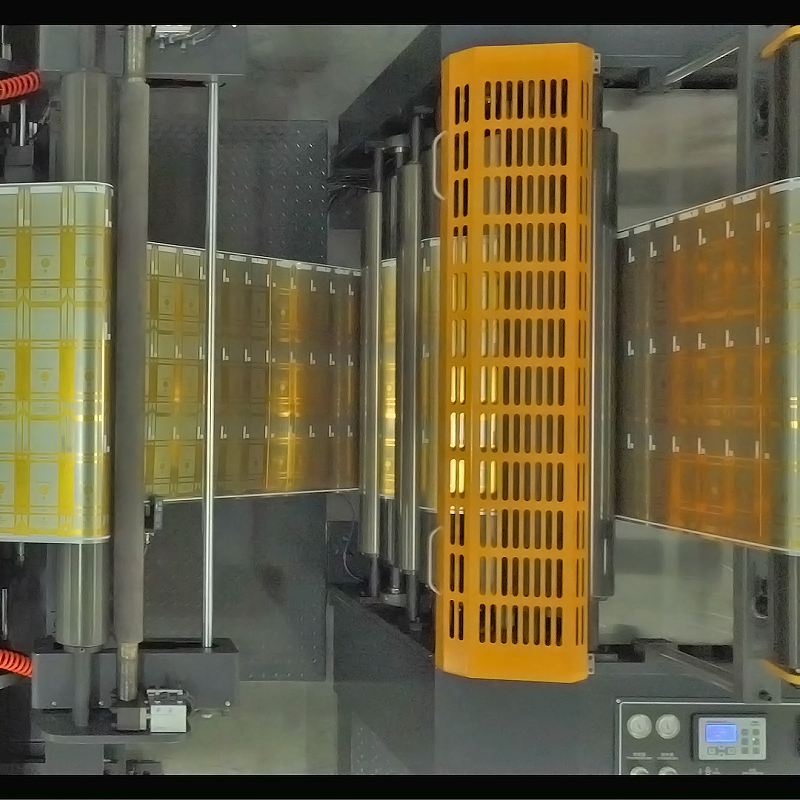

Safety and quality control are paramount in the factory's manufacturing process. Every machine undergoes extensive testing, including stress analysis and durability trials under maximum load conditions. The implementation of multiple safety features, such as infrared light barriers, two-hand operation controls, and emergency stop systems, ensures operator protection. Quality assurance protocols include detailed documentation of each production phase, regular calibration of testing equipment, and thorough performance validation before shipping. The factory maintains ISO 9001 certification and complies with international safety standards, providing customers with peace of mind and reliable operation.