Quality Assurance Excellence

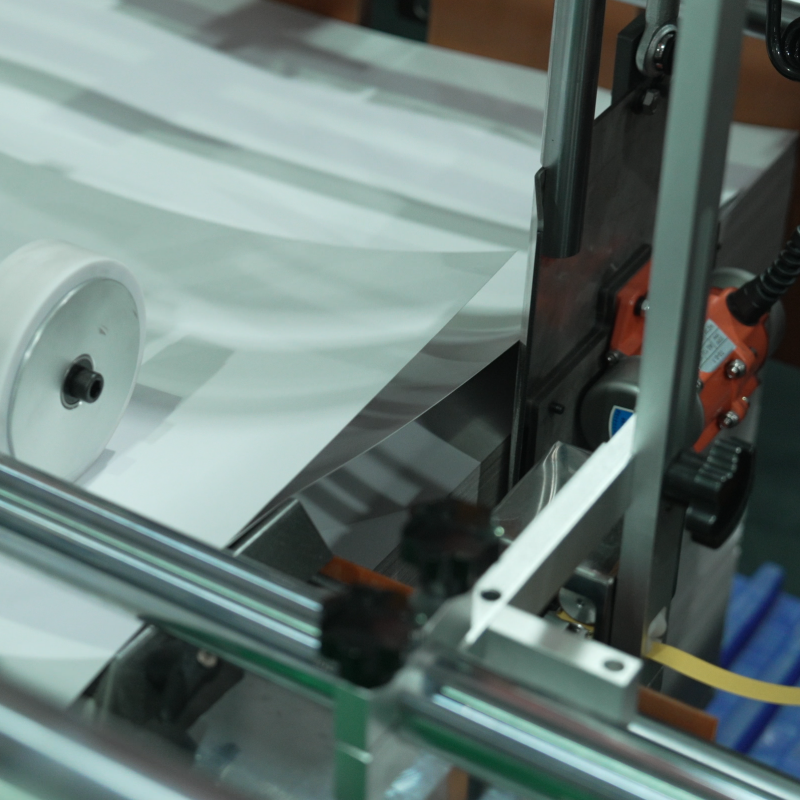

The factory implements a comprehensive quality assurance system that sets new standards in the industry. Every paper trimmer undergoes multiple inspection stages, utilizing advanced testing equipment to verify cutting precision, alignment accuracy, and operational stability. The quality control process includes automated optical inspection systems that detect even minor deviations from specifications. Each machine undergoes extensive durability testing under simulated heavy-use conditions to ensure long-term reliability. The factory maintains detailed quality records for each unit produced, enabling complete traceability and continuous process improvement.