Advanced Control System Integration

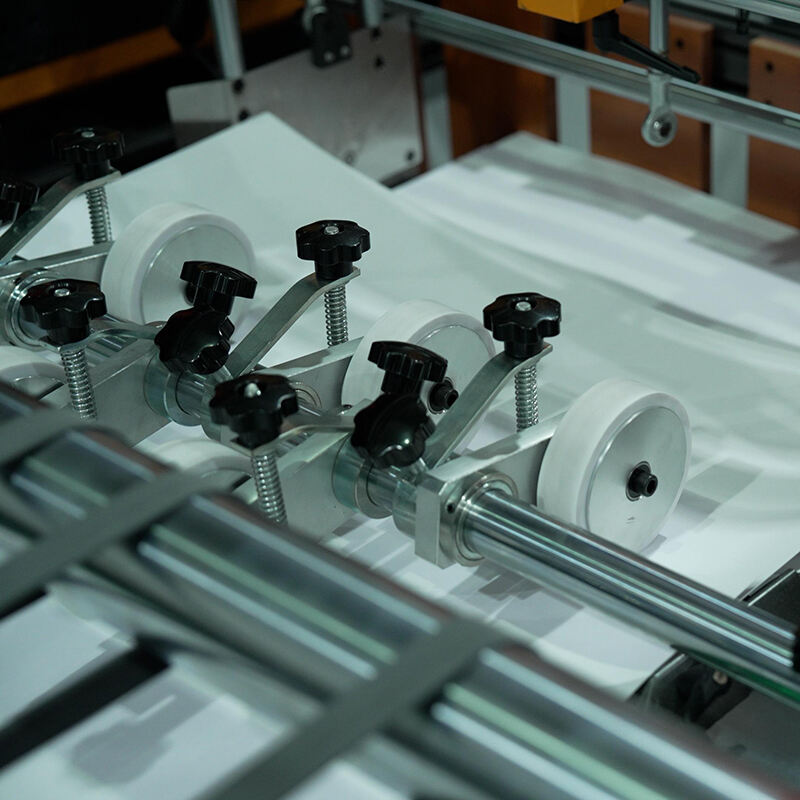

The rotary sheet cutting machines sophisticated control system represents a breakthrough in precision manufacturing technology. This integrated system combines state-of-the-art sensors, digital controls, and automated adjustment mechanisms to ensure optimal cutting performance under various conditions. The control system continuously monitors cutting parameters such as blade pressure, speed, and material feed rate, making real-time adjustments to maintain consistent quality. Operators can easily program and store multiple cutting profiles for different materials and specifications, enabling quick changeovers and reducing setup time. The system also includes diagnostic capabilities that help prevent maintenance issues and optimize machine performance, contributing to increased uptime and productivity.