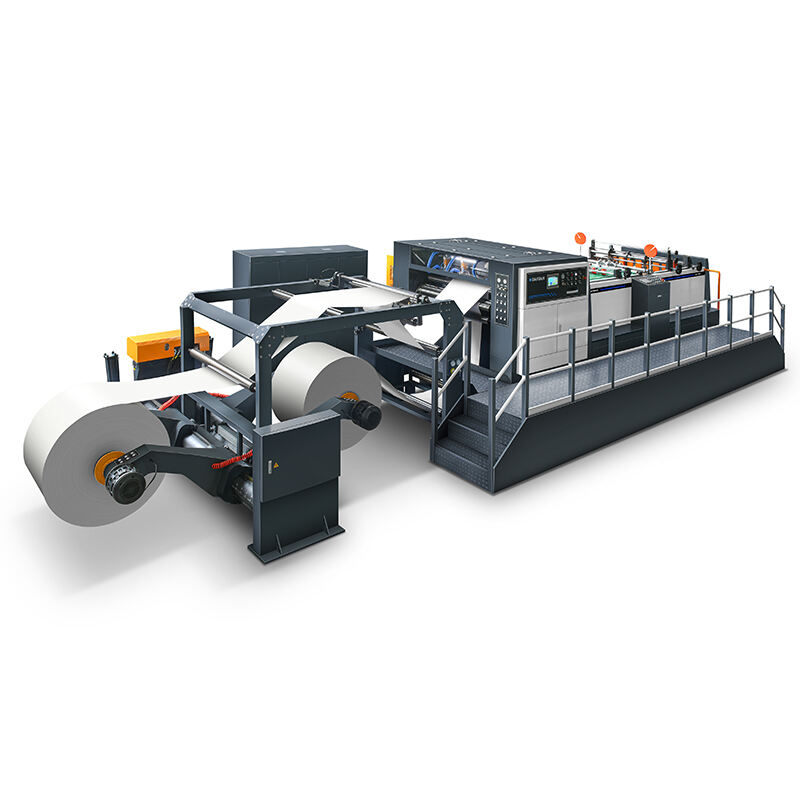

Precision Engineering and Control Systems

The die card cutter's precision engineering represents a breakthrough in manufacturing technology, incorporating advanced control systems that ensure unprecedented accuracy in cutting operations. The machine utilizes high-precision stepper motors and sophisticated pressure sensors that continuously monitor and adjust cutting force during operation. This intelligent system maintains optimal cutting pressure across different materials and thicknesses, preventing common issues like incomplete cuts or material damage. The control interface features intuitive digital displays and programmable settings, allowing operators to fine-tune parameters for specific applications. Advanced position tracking ensures precise alignment of cuts, while the automated depth control system prevents over-cutting and extends die life. The machine's frame is constructed from rigid materials that minimize vibration and maintain alignment during operation, ensuring consistent results even during extended production runs.