MHK-2S920TRC

DUOPRESS Makinë Automatike me Shpejtësi të Lartë për Ngjyrëzim Termik & Prerje me Çelës

- Patent izgjerimi: masina e parë në bot për larg të shumta stacione që kontrollohet pavarésisht nga motorë servomekanikë

- Përshtatje fleksibël për kërkesa procesi të komplekse

- Sigurojnë akuracijë të largta dhe efekte të stampimit të folive ndërkohë që arrin shpejtishte deri në 7.200 faqe/orë

- Përmbledhje

- Parametrat teknike

- Produkte të Lidhura

- FAQ

Përshkrimi i Produktit

Makina e shpejtë e nxehtë e markës Dayuan MHK-seria DUOPRESS me shtampim automatik dhe prerje me matricë me çelësim është projektuar për përpunim njëpasnjësh, duke integruar shtampimin me folje, prerjen me matricë dhe çelësimin në një operacion të vetëm, shumë të efikas—i përshtatshëm për kërkesat e shtampimit kompleks me folje në paketimin e duhanit premium, paketimin e alkoolit dhe aplikime të tjera të larta. Duke maksimizuar prodhueshmërinë dhe minimizuar kostot e punës, ky prerës automatik me matricë ofron vlera të jashtëzakonshme dhe konkurrencë të rritur, duke e bërë atë zgjedhjen ultimative për tregun e lartë të pas-printimit.

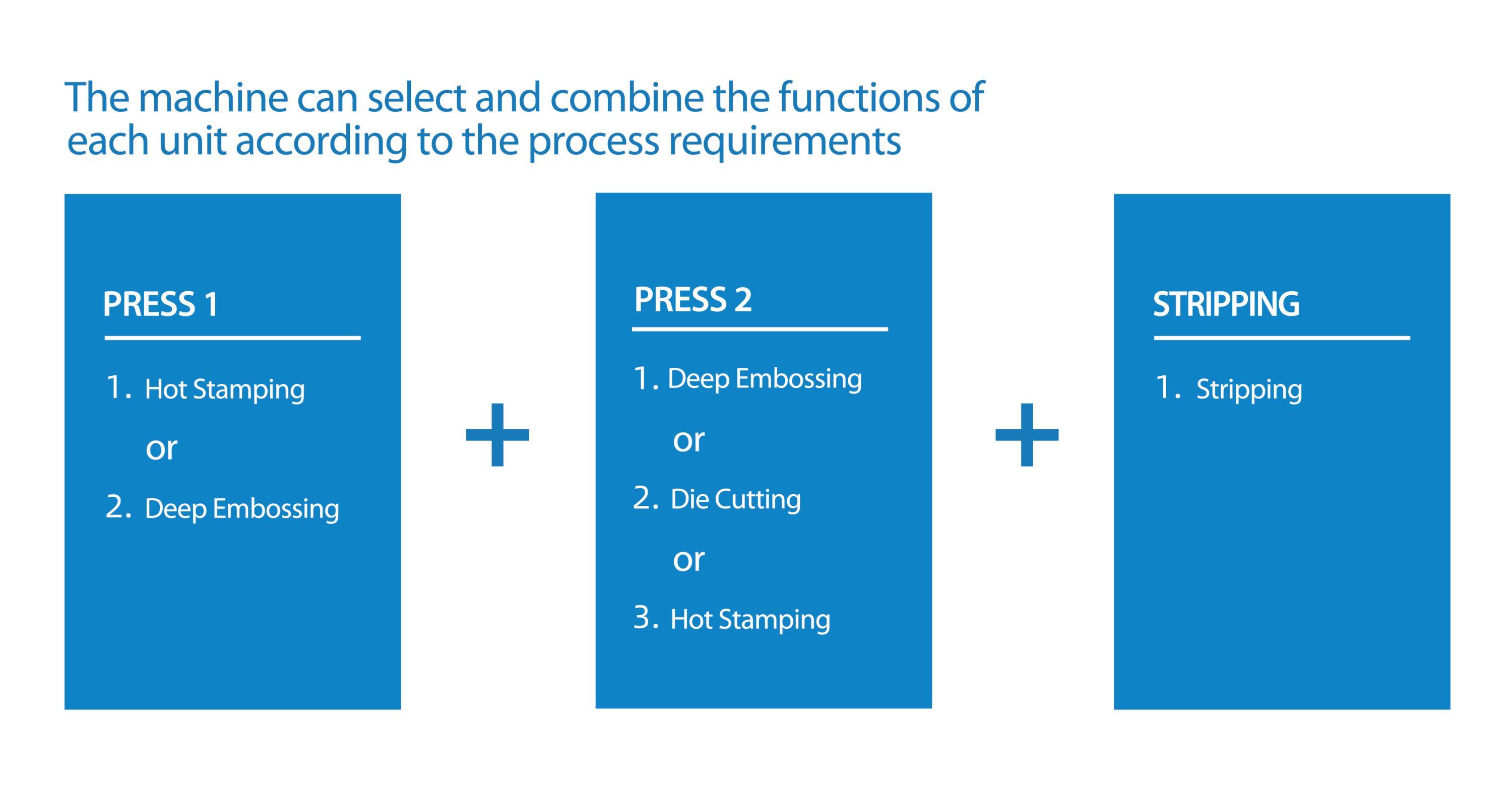

Përshtatje Larg:

•Konfigurimi modulare i procesit u përgatit sipas kërkesave të produktit, me çdo unitë që kontrollohet pavarësisht nga motorët servo për operatën e vetme të opsionit.

•Përmban stampim holografik, stampim trefol, embosim thell, duar dhe largim i shkatellave për të plotësuar nevojat e ndryshme të prodhimit dhe të rritur efikasitetin shtesërisht.

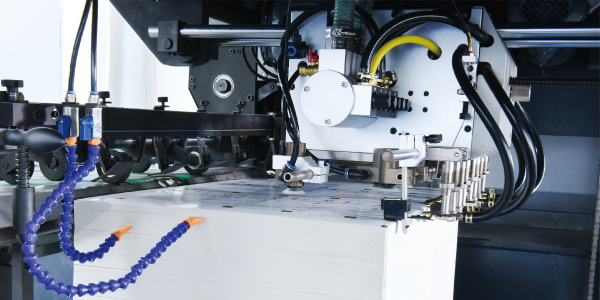

Përformanca Siguruese:

•Shpejtia maksimale: 7,200 faqe/të; presja maksimale: 600 tonat.

•E pajisur me sistem kontrolli të stampimit me folje të pronë dhe sistem të ushqimit të foljes, ajo mbështet stampimin horizontal dhe vertikal për të plotësuar kërkesat e cilësisë premium, me saktësi prej ±0.1mm.

•Sistemi i kontrollit të servo të pozicionimit të pasdites të barrës së shkaktuar, i patenton, garanton precizion të përgjithshëm të ±0.075mm.

Versatilitet i shkëlqyeshëm:

•Mbulon stampimin e nxehtë dhe reliefin në lloje të ndryshme materjalësh.

•E përshtatshme për përpunimin e grafikave me strukturë komplekse në industrinë e shtypit dhe të paketimit.

•Lejon ndërrimin e lehtë dhe të shpejtë midis proceseve të stampimit me folje të nxehtë dhe prerjes me matricë.

Larg dhe efikasitet kushtor:

•Kadër i larg nga gjetë dhe i forcësuar garanton stabilitet.

•Mbulon konfigurimin e shpejtë dhe ndërrimin e shpejtë me pajisje mikroajsimi.

•Ndërfaqe njeri-makinë të përdorshme për operim intuitiv dhe efikas.

•Larg shumicëve pjesë veprimesh për mbështetje pas shitjes.

|

|

|

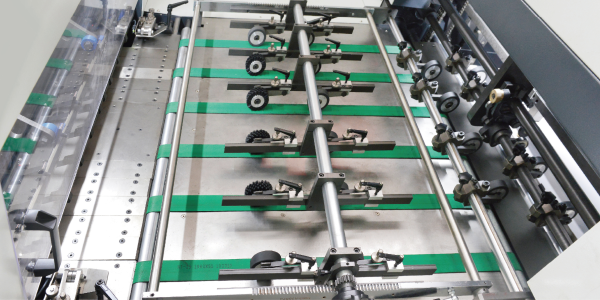

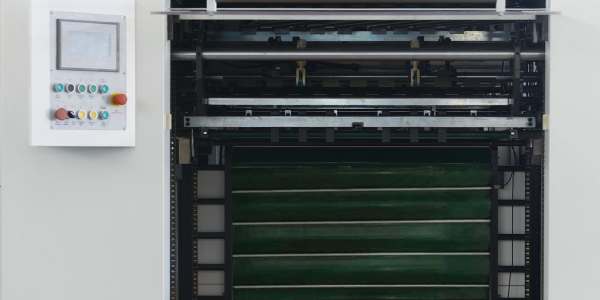

Udhëzues (4 tërheqje dhe 6 dorëzime) |

Njësi për transmetim letre |

GAUGE PARA & GAUGE ANËTARE |

|

|

|

Rrotë e dhëmbëzuar për rrip të kohës, Mekanizëm i ndërprerë |

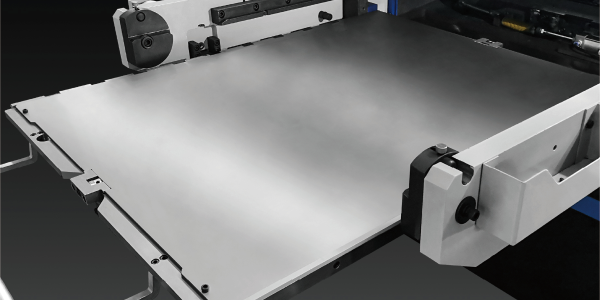

Kornizë me mikroajsim me pajisje përforcimi të shpejtë |

Plakë prerëse me mikroajsim |

|

|

|

Pajisje e vendosjes të shrutit e përgjithshme kontrolluar nga servo |

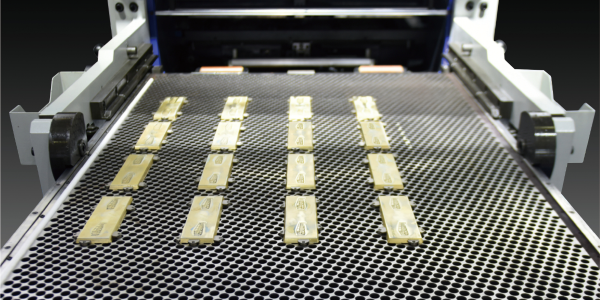

Plakë qelizore me mikroajsim |

SEKCIJA E LARGIMIT TË LARGUESHMEVE |

|

|

|

Pajisje për heqjen e kufijve të kapësve |

Pajisje për dorëzim letre të llojit tendë me rrotullim të pandërprerë |

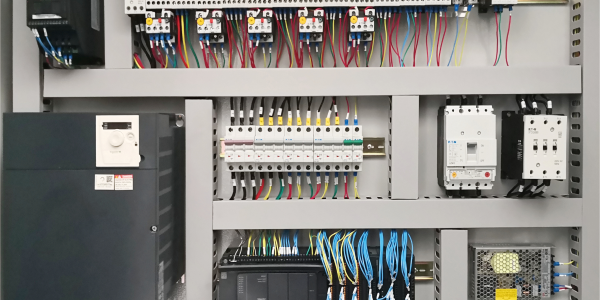

Larg Uniti Elektrik |

|

|

|

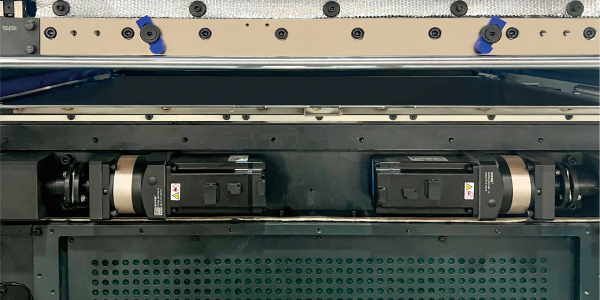

Pompa vakum Gjermane |

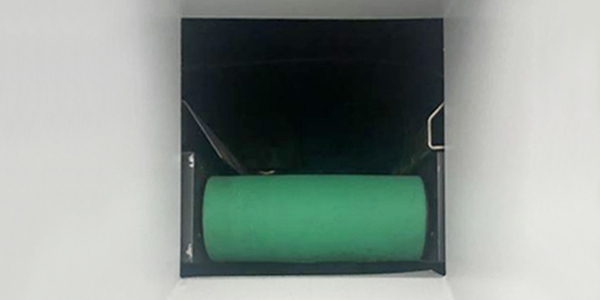

Sistem lubrifikimi automobil |

Mekanizëm i ftohjes/lubrifikimit të njësisë kryesore |

Parametrat teknike

|

Model |

MHK-2S920TT |

MHK-2S920TRC MHK-2S920TMC |

MHK-2S920RRC MHK-2S920RMC |

|

Madhësia maksimale e fletës |

920×650 |

920×650mm |

920×650mm |

|

Madhësia minimale e fletës |

360×320mm |

360×320mm |

360×320mm |

|

Madhësia maksimale e prerjes |

920×630mm |

920×630mm |

920×630mm |

|

Madhësia maksimale e stampimit |

900×600mm |

900×600mm |

/ |

|

Madhësia Maksimale e Largimit |

900×600mm |

900×600mm |

900×600mm |

|

Margjina minimale e kapëses |

9-17 mm |

9-17 mm |

9-17 mm |

|

Gjerësia Minimale e Largimit |

/ |

10-18mm |

10-18mm |

|

Madhësia e brendshme e ndihmës |

1008×670mm |

1008×670mm |

1008×670mm |

|

Gama e materialeve |

Kartoni: 80-2000g\/m², 0.1-2mm |

Kartoni: 80-2000g\/m², 0.1-2mm |

Kartoni: 80-2000g\/m², 0.1-2mm |

|

Saktësia e prerjes |

≤±0,075 mm |

≤±0,075 mm |

≤±0,075 mm |

|

Precizion e Përbashkët të Stemping |

≤±0.1 mm |

≤±0.1 mm |

/ |

|

Larg dhe vlerësimi i precizionit të stampimit |

≤±0.1 mm |

≤±0.1 mm |

/ |

|

Largimi me Saktësi |

≤±0,075 mm |

≤±0,075 mm |

≤±0,075 mm |

|

Shtyp 1 Larg dhe Forca Maksimale e Largimit |

600 T |

600 T |

600 T |

|

Shtyp 2 Larg dhe Forca Maksimale e Largimit |

600 T |

600 T |

600 T |

|

Maksimumi i Shpejtësisë së Punës |

7200s/h |

7200s/h |

7200s/h |

|

Lartësia maksimale e grumbullit në ngarkues - Modalitet normal |

1500mm |

1500mm |

1500mm |

|

Lartësia maksimale e grumbullit në dorëzim |

1300mm |

1300mm |

1300mm |

|

Diametri i Larg dhe i Gjithsej të Max.gold |

φ250mm Larg, φ200mm Larg dhe Larg |

φ250mm Larg, φ200mm Larg dhe Larg |

/ |

|

Sistemi elektrik i ngrohjes |

20 Zonat e largimit të ndryshueshme, 40-180℃ Përpjestim i rregullueshëm |

20 Zonat e largimit të ndryshueshme, 40-180℃ Përpjestim i rregullueshëm |

20 Zonat e largimit të ndryshueshme, 40-180℃ Përpjestim i rregullueshëm |

|

Gjerësia e folesë |

20-900mm |

20-900mm |

/ |

|

Shtylla e avancimit të folesë 1 |

3 Larg + 2 Larg (përplas) |

3 Larg + 2 Larg (përplas) |

Sistemi elektrik i ngrohjes |

|

Shtylla e avancimit të folesë 2 |

3 Larg + 2 Larg (përplas) |

Sistemi i Larg dhe Zbatimi me Larg (TRC) |

Sistemi i Larg dhe Zbatimi me Larg (RRC) |

|

Larg dhe Zbatim me Larg (TMC) |

Larg dhe Zbatim me Larg (RMC) |

||

|

Fuqia e plotë e ngarkesës |

108kw |

96KW / 86KW |

84KW / 74KW |

|

Kërkesa për Ajër |

0.6-0.7MPa,≥1m3/min |

0.6-0.7MPa,≥1m3/min |

0.6-0.7MPa,≥1m3/min |

|

Pesha neto e makinës |

29T |

28T |

27T |

|

Përmasat e Makinës (Përfshirë Ngarkuesin e Dijve)(G×L×LÂ) |

7615×6960×2658mm |

7615×6960×2658mm |

7615×6960×2658mm |