Понимание влияния технологии вырубки на бизнес

В современной конкурентной производственной среде решение об инвестировании в плоскоформатный рубительный пресс представляет собой важнейший шаг к расширению производственных возможностей и достижению операционного совершенства. Эти сложные машины произвели революцию в подходе компаний к процессам вырубки, биговки и отделки, особенно в бумажной и упаковочной промышленности.

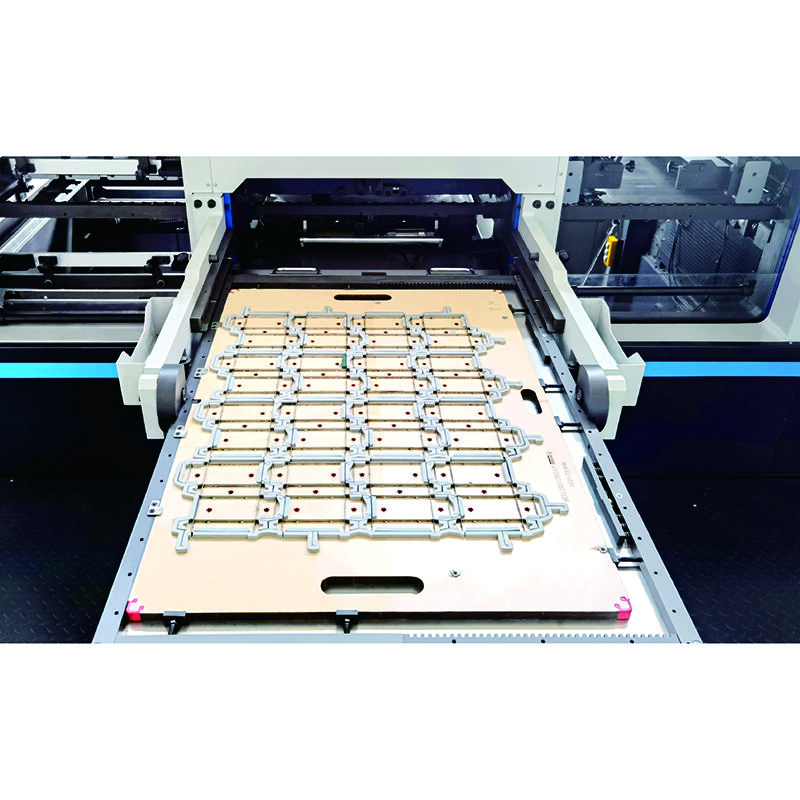

Современный плосковырубной пресс объединяет точную инженерную конструкцию с передовой автоматизацией, предоставляя производителям возможность обрабатывать материалы, такие как толстый картон и глянцевая фотобумага, с беспрецедентной точностью и эффективностью. Когда компании оценивают свои инвестиции в оборудование, понимание всесторонних преимуществ и потенциальной отдачи от инвестиций становится ключевым фактором для принятия обоснованного решения.

Основные преимущества систем плосковального штампования

Эффективность производства и оптимизация скорости

Внедрение плосковырубного пресса кардинально преобразует производственные процессы за счёт автоматизации ранее ручных операций. Эти машины способны обрабатывать сотни листов мелованной или двусторонней офсетной бумаги в час с постоянной точностью, значительно сокращая время, необходимое для сложных операций вырубки. Автоматические системы подачи и выгрузки обеспечивают непрерывную работу при минимальном вмешательстве оператора, что приводит к увеличению производительности и снижению затрат на рабочую силу.

Современные системы плоских штанцевальных прессов оснащены передовыми системами регистрации, которые обеспечивают точное позиционирование на протяжении всего производственного процесса, минимизируя отходы и гарантируя стабильное качество. Такой уровень автоматизации позволяет компаниям с уверенностью браться за крупные заказы, зная, что они смогут выполнить их в жесткие сроки, сохраняя высокие стандарты качества.

Версатильность материалов и диапазон применения

Одним из самых привлекательных преимуществ инвестиций в плосковырубной пресс-нож является его исключительная универсальность при работе с различными видами бумаги. Он одинаково хорошо справляется как с плотной крафт-бумагой для упаковки, так и с тонкой художественной бумагой для специализированных задач. Благодаря такой универсальности компании могут расширять ассортимент своей продукции — от индивидуальных коробок до сложных канцелярских изделий — и выходить на новые рынки без дополнительных капиталовложений в оборудование.

Возможность обработки бумаги разной плотности и с разными покрытиями также позволяет компаниям быстро адаптироваться к изменяющимся рыночным требованиям и пожеланиям клиентов. Независимо от того, производятся ли высококачественные упаковочные решения из толстого картона или детализированные рекламные материалы из художественной бумаги, один плосковырубной пресс-нож способен справляться с различными задачами при минимальных изменениях настройки.

Эксплуатационная надежность и преимущества в обслуживании

Переход на передовые системы плоских штамповочных прессов обеспечивает значительное повышение эксплуатационной надежности, которое выходит за рамки чисто финансовых показателей. Эти точные машины спроектированы для непрерывной работы в сложных производственных условиях и значительно сокращают незапланированные простои, традиционно характерные для ручных процессов резки. Благодаря интегрированным системам мониторинга и возможностям самодиагностики современные штамповочные прессы могут прогнозировать потребность в техническом обслуживании до того, как она перерастёт в дорогостоящие перебои в производстве, обеспечивая стабильное качество продукции при обработке чувствительных материалов, таких как тиснёная бумага и специальные покрытия.

Система обслуживания, поддерживающая эти системы, значительно эволюционировала и включает модульные компоненты, которые можно заменять без остановки целых производственных линий. Многие производители теперь предоставляют услуги удаленной диагностики и прогнозируемого технического обслуживания, позволяя техникам выявлять потенциальные проблемы через цифровые интерфейсы до того, как они повлияют на производственные графики. Такой проактивный подход к управлению оборудованием превращает техническое обслуживание из реактивной статьи расходов в стратегическое преимущество, что особенно важно для предприятий, работающих в несколько смен или выполняющих заказы по принципу «точно в срок» для клиентов премиальной упаковки.

Стратегии внедрения и интеграции

Обучение и развитие персонала

Успешная интеграция плосковырубного пресса в существующие операции требует всесторонних программ обучения для операторов и технического персонала. Хотя эти машины являются высокопроизводительными, квалифицированные операторы необходимы для обеспечения оптимальной производительности и устранения неисправностей, гарантируя стабильное качество при выполнении работ, таких как печать на мелованной бумаге. Инвестиции в обучение обеспечивают максимальное использование оборудования и сокращают простои из-за ошибок операторов.

Многие производители предлагают подробные программы обучения и постоянную поддержку, чтобы помочь компаниям развивать внутреннюю экспертизу. Передача знаний имеет решающее значение для поддержания стабильного качества производства и достижения ожидаемой отдачи от инвестиций.

Оптимизация рабочих процессов

Для получения максимальной выгоды от использования плосковырубного пресса предприятиям следует тщательно спланировать его интеграцию в рабочий процесс. Это включает анализ текущих производственных процессов, выявление потенциальных узких мест и внедрение изменений для оптимизации потока материалов и обработки заказов — независимо от того, работают ли они с большими рулонами культурной бумаги или предварительно нарезанными пачками двусторонней офсетной бумаги. Эффективное планирование обеспечивает бесперебойную интеграцию и минимальные нарушения в существующих операциях.

Рассмотрите возможность внедрения цифровых систем управления рабочими процессами, которые могут напрямую взаимодействовать с пробивным станком, обеспечивая автоматическое планирование задач и мониторинг производства в реальном времени. Такой уровень интеграции повышает общую операционную эффективность и предоставляет ценную информацию для инициатив по постоянному совершенствованию.

Часто задаваемые вопросы

Какой типичный срок службы плоскошлифовального пресса?

При надлежащем обслуживании и регулярном обслуживании качественная плоская резачка может работать эффективно в течение 15-20 лет. Многие производители предлагают комплексные программы технического обслуживания и легкодоступные заменные части, чтобы обеспечить долгосрочную надежность и производительность.

Через какое время можно ожидать возврата инвестиций?

Период рентабельности инвестиций варьируется в зависимости от объема производства и использования, но большинство предприятий достигают полной отдачи в течение 18-24 месяцев. Компании с большим объемом производства могут получить прибыль еще раньше, особенно если учесть экономию рабочей силы и увеличение возможностей получения дохода от обработки специализированных материалов, таких как глянцевая фотобумага.

Какие факторы следует учитывать при выборе плоскошлифовального пресса?

Ключевые соображения включают требования к объему производства, конкретные типы бумаги, которые должны быть обработаны (например, толщина картона по сравнению с GSM художественной бумаги), доступное пространство, необходимый уровень автоматизации и планы будущего роста. Также важно оценить инфраструктуру поддержки производителя, включая программы обучения, услуги по техническому обслуживанию и доступность запасных частей.