Understanding Modern Paper Die Cutting Technology for Production Excellence

The precision demanded in the modern printing and packaging industries, particularly in processing paper and cardboard, has made the flatbed die cutter an indispensable piece of equipment. This specialized machine transforms paper sheets into precisely cut products, ranging from custom boxes and greeting cards to intricate labels and point-of-sale displays. If you're looking to invest in new equipment, understanding the specific features of paper-focused flatbed die cutters is crucial for a smart, long-term decision.

Today's flatbed die cutters designed for paper and paperboard only represent the pinnacle of cutting technology. They combine refined mechanical engineering with advanced digital controls, delivering the high speed and accuracy necessary to handle the delicate yet demanding process of cutting paper materials. The right choice will significantly boost your production efficiency, minimize paper waste, and allow you to take on more complex paper-based projects.

Essential Features and Specifications for Paper Die Cutting

Cutting Force and Pressure Distribution (Paper-Specific)

While paper and paperboard require less overall force than materials like plastic or metal, the consistency and uniformity of the cutting pressure are paramount.

-

Optimized Pressure: Flatbed cutters designed solely for paper and cardboard are engineered to deliver precise, controlled pressure. Look for machines that specify their capability for micro-flute to heavy corrugated board, ensuring they can handle the full range of paper-based stock you use.

-

Uniform Pressure Systems: Premium models feature sophisticated pressure distribution systems. This ensures that the cutting force is applied uniformly across the entire sheet. This is essential for preventing crushing or tearing on delicate paper stock and achieving clean edges even on the smallest, most intricate cuts. Inconsistent pressure often leads to costly paper waste and lower product quality.

Working Area and High-Speed Paper Handling

The machine's working area should align with your largest paper sheet size, but for paper-based operations, the speed and reliability of material feeding are often the key to maximizing throughput.

-

Working Area: Standard sizes vary greatly, but choose a size that comfortably accommodates your most common sheet formats, with a buffer for future project expansion.

-

Automated Paper Feeding: For high-volume paper production, look for advanced, non-stop, automated feeding systems. Features like suction-cup feeders and pre-stacking capabilities are crucial for maintaining continuous operation.

-

Precise Registration: An excellent paper die cutter must have high-precision registration controls (often using photo-sensors) to perfectly align the pre-printed paper sheet with the cutting die. This is vital for projects requiring accurate cut-to-print alignment, such as packaging and labels.

Advanced Control Systems and Automation for Paper Workflow

Digital Interface and Programming Options

Modern paper die cutters are controlled by sophisticated digital interfaces that streamline operations and reduce setup time.

-

Intuitive Controls: Look for systems with large touch-screen controls and user-friendly software. This simplifies the setting of critical parameters like cutting force and dwell time, which are key to achieving perfect results on different weights of paper.

-

Job Memory: The ability to save and quickly recall cutting programs for specific paper types and projects dramatically speeds up job changeovers. This is especially valuable in a print shop environment where production frequently switches between different paper stocks (e.g., from thin label paper to thick cardstock).

Automation and Waste Management

Paper production generates significant waste (skeletons and internal waste), so integrated waste removal is a critical feature.

-

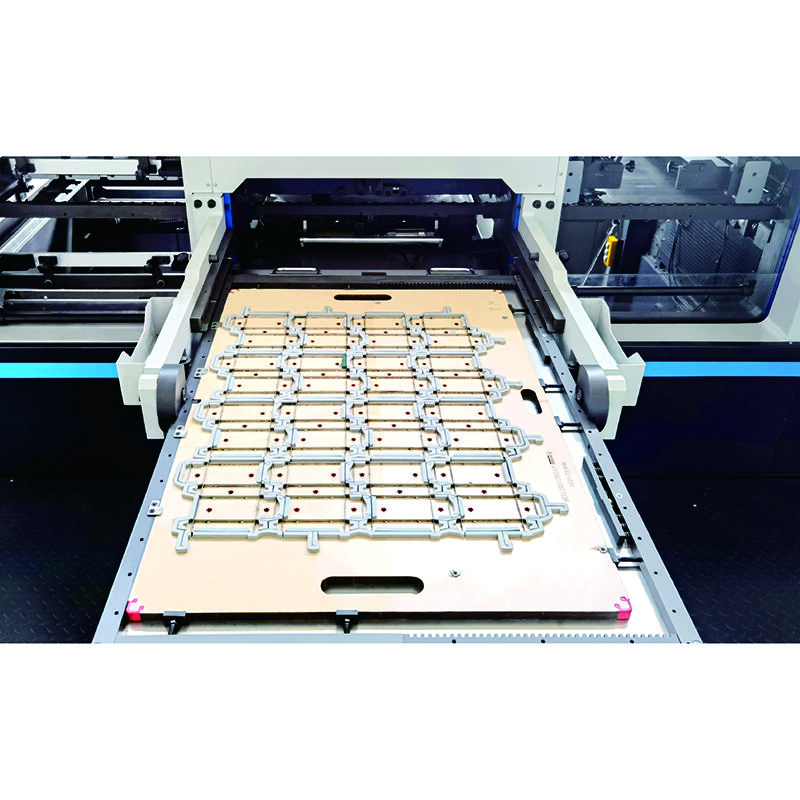

Stripping Capabilities: High-end models feature automated stripping stations that use pins and presser bars to rapidly and cleanly remove the skeletal waste from the cut paper sheet. This is a massive time-saver compared to manual stripping.

-

Blanking: For certain types of paper packaging, blanking (separating the finished products from the sheet) is a valuable feature that prepares stacks of finished items ready for the next stage, such as gluing or shipping.

Investment and Long-Term Considerations

Total Cost of Ownership (TCO)

When evaluating a paper-specific flatbed die cutter, focus on the long-term operational costs, not just the purchase price.

-

Energy Efficiency: Paper die cutters are run constantly in many facilities. Look for energy-efficient motor and drive systems, as lower power consumption can lead to substantial savings over the machine’s lifespan.

-

Consumables and Tooling: Consider the lifespan and cost of die boards and counter plates. A machine that maximizes die life and minimizes setup waste provides a better TCO.

Productivity and ROI Analysis

The return on investment (ROI) for a die cutter is directly tied to its speed, accuracy, and the reduction in labor and waste.

-

High-Speed Throughput: Since paper is relatively easy to cut, the limiting factor is often the machine's cycling speed (sheets per hour). Investing in a faster machine can quickly justify the higher initial cost through increased production capacity.

-

Reduced Waste: Every spoiled sheet of printed paper is a loss of time and material. A highly accurate machine with superior registration and pressure control minimizes waste, which is the single biggest factor improving ROI in paper converting.

Frequently Asked Questions

How do I choose the right cutting force for paper?

For paper and paperboard, you don't need excessive force. Focus instead on the machine's ability to maintain precise and consistent pressure distribution across the entire sheet. A well-designed machine with moderate, steady force will outperform a high-force machine with inconsistent pressure when cutting paper.

What’s the most important automation feature for high-volume paper cutting?

The automated non-stop feeder and the automated stripping station are the most critical features for maximizing throughput and reducing labor in high-volume paper operations. They allow the machine to run continuously with minimal operator intervention.

Can a paper die cutter also handle corrugated cardboard?

Most robust paper flatbed die cutters are designed to handle a range of paperboard, from thin stock up to heavy corrugated board (like E-flute or B-flute). Always verify the machine's specified maximum material thickness to ensure it covers the full range of paper-based materials you intend to process.