Essential Die Cutting Machine Tips and Techniques

The die cutting machine stands as a cornerstone in modern manufacturing, transforming raw materials into precisely shaped products with remarkable efficiency. From packaging and industrial applications, these versatile machines have revolutionized production processes across multiple industries. Understanding how to optimize their operation is crucial for achieving superior results and maintaining productivity.

Understanding Die Cutting Machine Fundamentals

Basic Operating Principles

At its core, a die cutting machine operates by applying pressure to press a sharp steel rule die against material, creating clean cuts in precise shapes. Modern industrial die cutting machine systems incorporate advanced features like automatic feeding, pressure adjustment, and digital controls to enhance precision and efficiency.

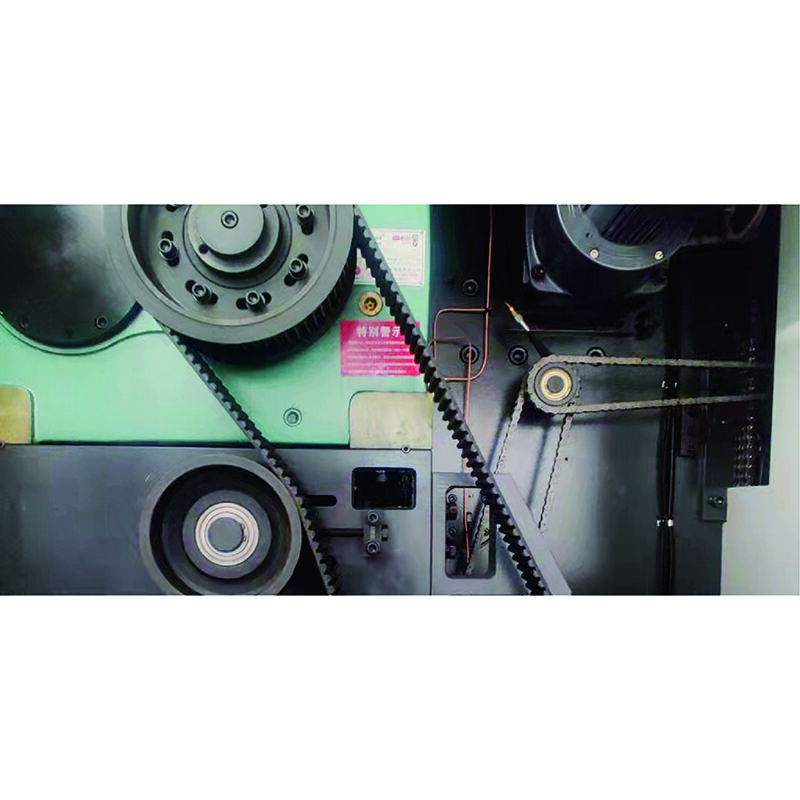

Machine Components

Every die cutting machine consists of essential components including the cutting plate, die board, counter plate, and pressure system. Understanding these elements helps operators maintain optimal performance and troubleshoot potential issues effectively. The cutting plate provides the foundation for the entire process, while the die board holds the steel rule dies in perfect alignment.

Optimizing Production Efficiency

Material Selection and Preparation

Successful die cutting begins with proper material selection and preparation. Different materials require specific die cutting machine settings and blade types. Temperature, humidity, and material thickness all play crucial roles in achieving clean, precise cuts. Operators must ensure materials are properly conditioned and stored before processing.

Maintenance Protocols

Regular maintenance ensures consistent performance from your die cutting machine. This includes daily cleaning routines, regular blade inspection and replacement, and systematic checking of all moving parts. Implementing a preventive maintenance schedule helps avoid costly downtime and extends equipment life.

Advanced Techniques and Applications

Precision Control Methods

Modern die cutting machine technology offers unprecedented control over cutting parameters. Digital pressure adjustment, speed control, and depth settings allow operators to fine-tune operations for different materials and specifications. These adjustments require careful calibration and monitoring to maintain optimal performance.

Multi-layer Processing

Advanced die cutting machines can handle multiple layers simultaneously, significantly increasing productivity. This capability requires precise material stacking and careful attention to pressure distribution. Operators must master the balance between speed and precision when processing multiple layers.

Troubleshooting and Quality Control

Common Issues and Solutions

Even well-maintained die cutting machines may encounter operational challenges. Understanding common issues like uneven cutting, material shifting, or pressure inconsistencies helps operators quickly identify and resolve problems. Regular quality checks and documentation of solutions build valuable operational knowledge.

Quality Assurance Measures

Implementing robust quality control measures ensures consistent output quality. This includes regular sample testing, measurement verification, and detailed record-keeping of machine settings and performance metrics. Establishing clear quality standards helps maintain production excellence.

FAQ

What factors affect die cutting machine performance?

Machine performance is influenced by multiple factors including material properties, environmental conditions, die quality, and maintenance practices. Regular calibration and proper operator training are essential for optimal results.

How often should die cutting machine maintenance be performed?

Daily cleaning and inspection are necessary, while more comprehensive maintenance should be scheduled weekly or monthly depending on usage patterns. Critical components should be checked and serviced according to manufacturer specifications.

What are the key considerations for material selection?

Material selection depends on the specific application requirements, including thickness tolerance, surface finish, and structural properties. Consider both the material's physical properties and how they interact with your die cutting machine settings.