Print shops today face increasing pressure to deliver high-quality finishing services while maintaining competitive pricing and operational efficiency. Investing in a creasing machine represents a significant decision that can dramatically impact a business's profitability and service capabilities. Understanding the return on investment for this essential equipment requires careful analysis of both direct costs and long-term benefits. Modern print operations demand precision finishing solutions that can handle diverse substrates and complex creasing patterns while maintaining consistent quality standards across large production runs.

Initial Investment Considerations for Creasing Equipment

Capital Equipment Costs and Financing Options

The upfront cost of a creasing machine varies significantly based on automation level, production capacity, and feature sophistication. Entry-level manual units typically range from fifteen thousand to thirty thousand dollars, while fully automated systems with advanced digital controls can exceed one hundred thousand dollars. Print shops must evaluate their current volume requirements and growth projections to select equipment that matches both immediate needs and future expansion plans. Financing options including equipment leasing, manufacturer financing programs, and traditional bank loans each offer different advantages depending on cash flow situations and tax considerations.

Beyond the equipment purchase price, installation costs often add five to fifteen percent to the total investment. Professional installation ensures optimal performance and validates warranty coverage, making this expense essential rather than optional. Training costs for operators represent another crucial investment, typically ranging from two to five thousand dollars depending on equipment complexity and operator experience levels. Comprehensive training programs reduce startup time and minimize costly operational errors during the initial implementation period.

Space Requirements and Facility Modifications

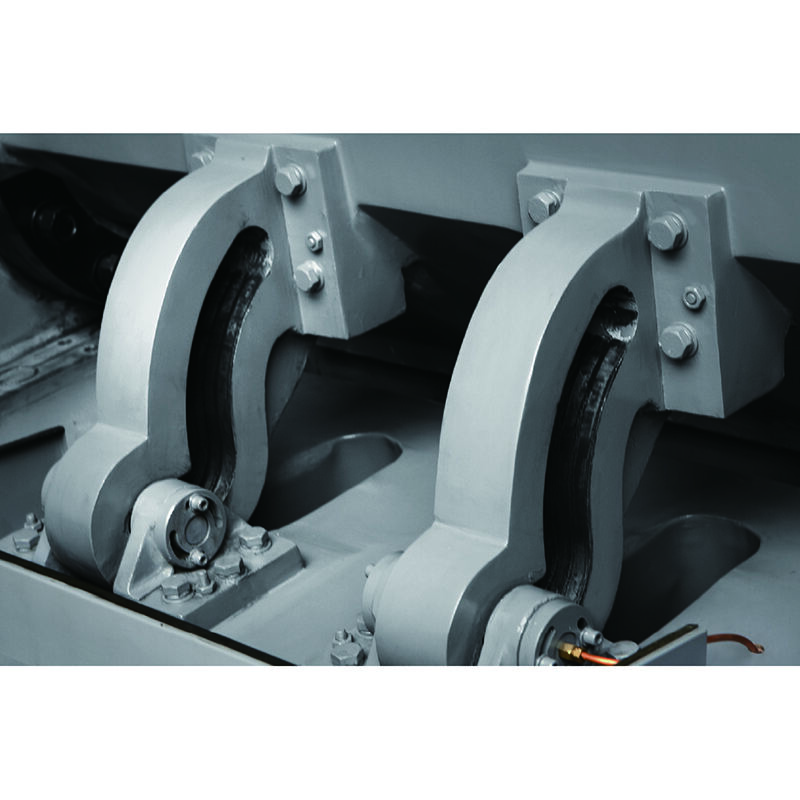

Integrating a creasing machine into existing print shop operations requires careful consideration of floor space, electrical requirements, and workflow integration. Most industrial creasing machines require dedicated floor space ranging from fifty to two hundred square feet, depending on feeding mechanisms and output handling systems. Electrical requirements often necessitate upgraded power supplies, particularly for automated systems requiring three-phase power connections and specialized control circuits.

Workflow optimization becomes critical when introducing new finishing equipment, as inefficient material handling can negate productivity gains. Strategic placement near complementary equipment like die-cutting machines or folding systems creates efficient production cells that minimize handling time and reduce quality risks. Air filtration systems may require upgrades to manage paper dust and debris generated during high-volume creasing operations, protecting both equipment longevity and operator health.

Operational Cost Analysis and Efficiency Metrics

Labor Cost Implications and Productivity Gains

Manual creasing processes typically require skilled operators working at relatively slow speeds, making labor costs a significant factor in project pricing. Automated creasing machine systems can reduce labor requirements by sixty to eighty percent while increasing production speeds by three to five times compared to manual methods. These productivity improvements translate directly into reduced per-unit costs and increased capacity for handling larger orders or shorter turnaround times.

Operator skill requirements change significantly with automated equipment, shifting from manual dexterity to technical operation and quality control responsibilities. While initial training investments are higher, ongoing labor costs typically decrease as operators can manage multiple machines simultaneously and focus on quality assurance rather than repetitive manual tasks. Cross-training multiple operators ensures production continuity and provides scheduling flexibility for peak demand periods.

Material Waste Reduction and Quality Improvements

Precision creasing equipment dramatically reduces material waste compared to manual processes, with waste reduction rates often exceeding twenty percent on complex projects. Consistent crease placement and pressure application minimize setup waste and reduce the number of rejected pieces during production runs. Quality improvements extend beyond waste reduction, as precise creasing enhances fold quality and reduces stress cracking in coated substrates.

Substrate versatility represents another significant advantage, as modern creasing machine systems handle materials ranging from lightweight text papers to heavy cardboard and synthetic substrates. This capability allows print shops to expand service offerings without investing in multiple specialized tools. Reduced tool changeover times between different substrate types improve overall equipment utilization and scheduling flexibility.

Revenue Generation Opportunities and Market Expansion

Service Portfolio Enhancement and Premium Pricing

Professional creasing capabilities enable print shops to offer comprehensive finishing services that command premium pricing compared to basic printing services. High-quality creasing is essential for packaging applications, presentation folders, and marketing materials where fold quality directly impacts perceived value. Print shops with reliable creasing capabilities often become preferred vendors for clients requiring consistent finishing quality across multiple projects.

Turnaround time improvements create competitive advantages in markets where speed is critical. Automated creasing machine operations enable same-day or next-day completion of projects that previously required multi-day processing times. This capability allows print shops to capture urgent orders and charge premium pricing for expedited services while maintaining quality standards.

Market Expansion into Packaging and Specialized Applications

Packaging market opportunities represent significant revenue potential for print shops equipped with professional creasing capabilities. Box manufacturing, carton production, and specialty packaging applications require precise creasing for proper assembly and professional appearance. These markets often provide higher margins than traditional commercial printing while offering opportunities for long-term client relationships.

Specialized applications including architectural models, point-of-purchase displays, and custom presentation materials create niche market opportunities. These applications typically involve smaller volumes but command significantly higher pricing due to specialized requirements and limited competition. Building expertise in these niche markets can establish print shops as go-to providers for specialized creasing applications.

Long-term Financial Benefits and ROI Calculations

Equipment Depreciation and Tax Advantages

Creasing machine investments qualify for various depreciation schedules and tax benefits that improve overall return on investment calculations. Section 179 deductions allow immediate expensing of equipment purchases up to annual limits, providing significant first-year tax benefits. Accelerated depreciation schedules reduce taxable income over equipment life spans while preserving cash flow for other business investments.

Equipment financing interest may qualify as business expense deductions, further improving the effective cost of capital investments. Consulting with tax professionals ensures optimal structuring of equipment purchases to maximize available benefits. These considerations often make the actual cost of ownership significantly lower than initial purchase prices suggest.

Maintenance Costs and Equipment Longevity

Professional creasing equipment typically provides ten to fifteen years of reliable service with proper maintenance, making longevity a crucial factor in ROI calculations. Annual maintenance costs generally range from two to five percent of equipment value, with higher costs in early years decreasing as operators become proficient. Preventive maintenance programs reduce unexpected downtime and extend equipment life significantly.

Parts availability and service support vary significantly between manufacturers, making vendor selection crucial for long-term success. Established manufacturers typically provide better parts availability and technical support, reducing operational risks and maintenance costs. Service contracts may provide cost predictability and priority support but should be evaluated against in-house maintenance capabilities and local service availability.

FAQ

What factors determine the payback period for a creasing machine investment

Payback periods typically range from eighteen to thirty-six months depending on utilization rates, labor cost savings, and revenue expansion opportunities. High-volume operations with significant manual creasing requirements often achieve faster payback through labor savings and increased throughput. Service expansion into packaging or specialty applications can accelerate payback through premium pricing and new revenue streams.

How does creasing machine automation level affect return on investment

Automation level directly correlates with labor savings and production capacity, but also increases initial investment costs. Semi-automated systems often provide optimal ROI for medium-volume operations by balancing productivity improvements with reasonable capital requirements. Fully automated systems justify higher costs only when volume levels consistently utilize maximum capacity and labor savings offset increased equipment expenses.

What ongoing costs should be considered beyond equipment purchase price

Ongoing costs include maintenance supplies, replacement tooling, operator training updates, and potential facility modifications. Annual operating costs typically represent eight to twelve percent of equipment value including maintenance, supplies, and incremental utility costs. Insurance costs may increase slightly, but equipment financing costs decrease over time as principal balances decline.

How can print shops maximize ROI from creasing equipment investments

Maximizing ROI requires strategic scheduling to maintain high utilization rates, aggressive marketing of enhanced finishing capabilities, and continuous operator training to optimize efficiency. Developing expertise in high-margin applications like packaging or specialty materials creates pricing advantages. Regular maintenance and proper operation extend equipment life and reduce long-term costs while maintaining quality standards that support premium pricing.