Professional packaging and printing operations rely heavily on the precision and consistency of specialized equipment. Among the most critical pieces of machinery in modern production facilities is the creasing machine, which creates precise fold lines that ensure clean, professional-looking finished products. Proper maintenance of these sophisticated machines directly impacts production quality, operational efficiency, and long-term profitability. Understanding the fundamental principles of equipment care and implementing systematic maintenance protocols can significantly extend machine lifespan while minimizing costly downtime and repairs.

Understanding Creasing Machine Components

Core Mechanical Systems

The foundation of effective maintenance begins with comprehensive knowledge of your equipment's internal systems. Modern creasing machines incorporate multiple interconnected components that work in precise harmony to deliver consistent results. The primary mechanical systems include the feeding mechanism, which controls material input and positioning, and the creasing unit itself, where the actual fold formation occurs. These systems rely on carefully calibrated pressure settings, alignment specifications, and timing sequences that must be monitored regularly.

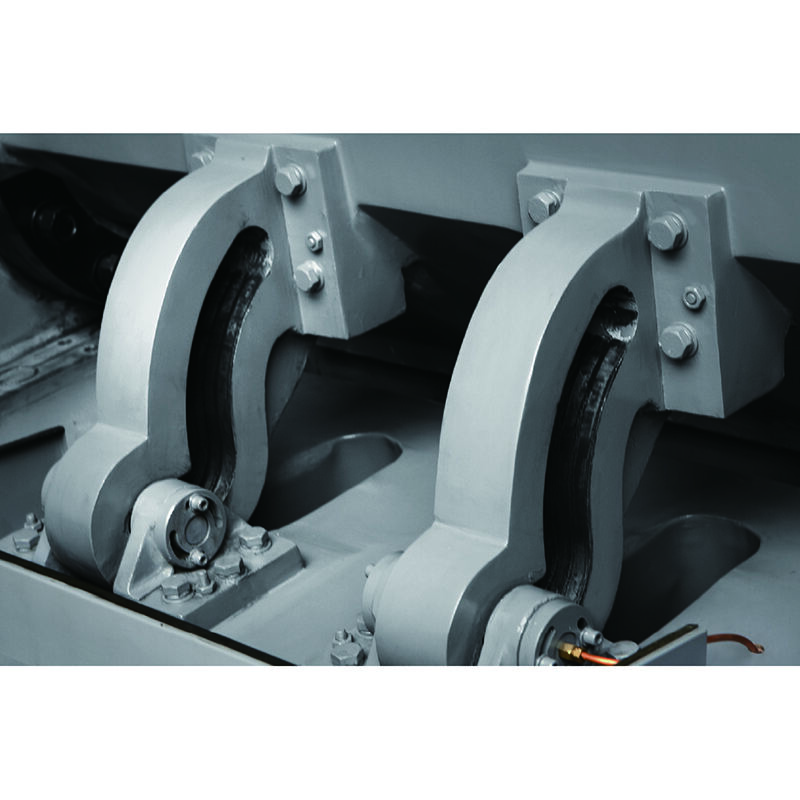

The feeding system typically consists of adjustable guides, vacuum-assisted conveyors, and registration sensors that ensure accurate material placement. Regular inspection of these components reveals wear patterns, alignment issues, or contamination that could compromise performance. The creasing unit contains the heart of the operation, featuring precision-ground creasing rules, counter-plates, and pressure adjustment mechanisms. Understanding how these elements interact allows operators to identify potential problems before they escalate into major failures.

Electronic and Control Systems

Contemporary creasing machines integrate sophisticated electronic controls that manage everything from speed regulation to quality monitoring. These systems include programmable logic controllers, human-machine interfaces, servo motors, and various sensors that provide real-time feedback on operational parameters. Regular software updates, calibration checks, and diagnostic procedures ensure these electronic components continue functioning optimally throughout their service life.

The control systems also manage safety interlocks, emergency stops, and operational monitoring functions that protect both equipment and personnel. Maintenance protocols should include regular testing of all safety systems, verification of sensor accuracy, and inspection of electrical connections for signs of corrosion, loosening, or damage. Proper documentation of all electronic system maintenance helps identify recurring issues and supports warranty claims when necessary.

Daily Maintenance Procedures

Pre-Operation Inspections

Establishing consistent daily maintenance routines forms the cornerstone of effective equipment care. Before beginning production operations, trained operators should conduct thorough visual inspections of all accessible components, checking for obvious signs of wear, damage, or contamination. This includes examining the creasing rules for nicks or burrs, verifying proper alignment of feeding mechanisms, and ensuring all safety guards are securely in place.

The pre-operation checklist should also include verification of all fluid levels, including hydraulic oil, lubricants, and coolants where applicable. Operators should test all control functions, emergency stops, and safety interlocks to ensure proper operation before beginning production runs. Any anomalies discovered during these inspections must be addressed immediately to prevent more serious damage or safety hazards.

Post-Operation Cleaning and Inspection

End-of-shift maintenance procedures focus on thorough cleaning and preparation for the next production cycle. This involves removing all debris, paper dust, and adhesive residue that accumulates during normal operation. Specialized cleaning solutions and tools designed for your specific creasing machine model ensure effective cleaning without damaging sensitive components or finishes.

Post-operation inspections should document any unusual wear patterns, performance variations, or mechanical issues observed during the production shift. This information proves invaluable for identifying developing problems and scheduling preventive maintenance activities. Proper lubrication of specified points according to manufacturer recommendations prevents premature wear and ensures smooth operation during subsequent production runs.

Preventive Maintenance Scheduling

Weekly Maintenance Tasks

Weekly maintenance activities build upon daily procedures by addressing components and systems that require less frequent attention but remain critical for long-term reliability. These tasks typically include more detailed inspections of drive systems, bearing assemblies, and mechanical linkages that may not be readily visible during daily checks. Operators should examine belt tension, chain alignment, and coupling integrity to identify signs of wear or misalignment.

Lubrication schedules often specify weekly intervals for certain components, particularly those subjected to high loads or frequent cycling. Proper selection and application of lubricants according to manufacturer specifications prevents contamination, ensures adequate protection, and maintains optimal operating temperatures. Documentation of all weekly maintenance activities supports warranty requirements and helps establish patterns that inform future maintenance decisions.

Monthly and Quarterly Procedures

Extended maintenance intervals allow for comprehensive system evaluations and component replacements that support long-term reliability. Monthly procedures typically include calibration checks of pressure systems, alignment verification of critical components, and detailed inspections of electrical connections and control circuits. These activities require specialized tools and training but provide essential insights into overall equipment condition.

Quarterly maintenance often involves component replacements, fluid changes, and comprehensive system testing that validates overall machine performance. These procedures may require temporary production shutdowns but prevent unexpected failures that could cause extended downtime and expensive emergency repairs. Professional service technicians often perform these complex procedures to ensure proper execution and maintain warranty coverage.

Troubleshooting Common Issues

Performance and Quality Problems

Even well-maintained equipment occasionally experiences performance issues that require systematic troubleshooting approaches. Common problems include inconsistent crease quality, feeding difficulties, and speed variations that impact production efficiency. Effective troubleshooting begins with careful observation of symptoms, documentation of operating conditions, and systematic elimination of potential causes.

Quality issues often stem from worn creasing rules, improper pressure settings, or contamination of critical surfaces. Methodical inspection and testing procedures help identify the root cause while avoiding unnecessary component replacements or adjustments that might create additional problems. Maintaining detailed records of troubleshooting activities supports pattern recognition and helps prevent recurring issues.

Mechanical and Electrical Failures

Mechanical failures in creasing machines typically involve bearing wear, drive system problems, or structural damage that affects alignment and operation. Early detection through regular inspections and condition monitoring prevents minor issues from escalating into major failures requiring extensive repairs or component replacements. Understanding the relationships between different mechanical systems helps operators identify potential failure modes and implement appropriate corrective actions.

Electrical failures often present more complex diagnostic challenges requiring specialized knowledge and test equipment. Common electrical problems include sensor malfunctions, control circuit failures, and motor issues that disrupt normal operation. Proper troubleshooting procedures for electrical systems emphasize safety protocols, systematic testing approaches, and professional assistance when dealing with high-voltage components or complex control systems.

Professional Service and Support

Manufacturer Service Programs

Most equipment manufacturers offer comprehensive service programs designed to support optimal machine performance throughout the equipment lifecycle. These programs typically include regular inspections by factory-trained technicians, preventive maintenance services, and access to genuine replacement parts and upgrades. Participating in manufacturer service programs often provides priority support, extended warranty coverage, and access to technical expertise that may not be available internally.

Professional service technicians bring specialized knowledge, diagnostic equipment, and experience working with similar machines in various applications. Their expertise proves particularly valuable for complex repairs, software updates, and performance optimization activities that require detailed understanding of machine design and operation. Regular professional service also helps identify opportunities for upgrades or modifications that could improve productivity or capabilities.

Training and Certification Programs

Investing in operator training and certification programs significantly improves maintenance effectiveness while reducing the likelihood of equipment damage due to improper procedures or techniques. Comprehensive training programs cover everything from basic operation principles to advanced troubleshooting and repair procedures. Well-trained operators can identify potential problems earlier, perform routine maintenance more effectively, and make informed decisions about when to seek professional assistance.

Certification programs validate operator competency and provide ongoing education about new technologies, maintenance techniques, and safety procedures. Many manufacturers offer training programs that combine classroom instruction with hands-on experience using actual equipment. These programs often include certification testing that documents operator qualifications and supports insurance requirements or regulatory compliance obligations.

FAQ

How often should I replace the creasing rules on my machine

Creasing rule replacement frequency depends on several factors including production volume, material types processed, and maintenance quality. Typically, rules should be replaced when they show visible wear, produce inconsistent crease quality, or reach the manufacturer's recommended usage limits. Most high-volume operations replace rules every 3-6 months, while lower-volume applications may extend this interval to 6-12 months. Regular inspection and quality monitoring help determine the optimal replacement schedule for your specific application.

What are the most critical lubrication points on a creasing machine

Critical lubrication points typically include all bearing assemblies, drive chains or belts, mechanical linkages, and any sliding or rotating surfaces subject to regular movement. The feeding mechanism guides, pressure adjustment systems, and motor bearings require particular attention to prevent premature wear. Always consult your machine's lubrication chart for specific intervals and lubricant specifications, as using incorrect products can cause damage or void warranty coverage.

How can I prevent paper dust buildup from affecting machine performance

Paper dust prevention requires a combination of proper ventilation, regular cleaning, and appropriate filtration systems. Install dust collection systems near cutting and creasing areas, maintain adequate air circulation to prevent dust accumulation, and establish daily cleaning routines that remove debris before it can interfere with mechanical components. Consider upgrading to equipment with integrated dust collection features if dust continues to be a significant problem in your operation.

What should I do if my creasing machine starts producing inconsistent fold quality

Inconsistent fold quality typically results from worn creasing rules, improper pressure settings, contamination of critical surfaces, or material feeding problems. Begin troubleshooting by inspecting the creasing rules for damage, verifying pressure settings match job requirements, and ensuring all surfaces are clean and properly aligned. If these basic checks don't resolve the issue, consult your maintenance documentation or contact professional service technicians for more comprehensive diagnosis and repair.