Modern manufacturing environments demand precision, efficiency, and reliability in every piece of equipment. A creasing machine represents a cornerstone of professional finishing operations, delivering consistent fold lines and enhanced product quality across diverse applications. These sophisticated machines have evolved significantly from their mechanical predecessors, incorporating advanced technologies that streamline workflow while maintaining exceptional accuracy. Understanding the features and capabilities of contemporary creasing machines enables businesses to make informed decisions that directly impact productivity and profitability.

Advanced Control Systems in Modern Equipment

Digital Interface Technology

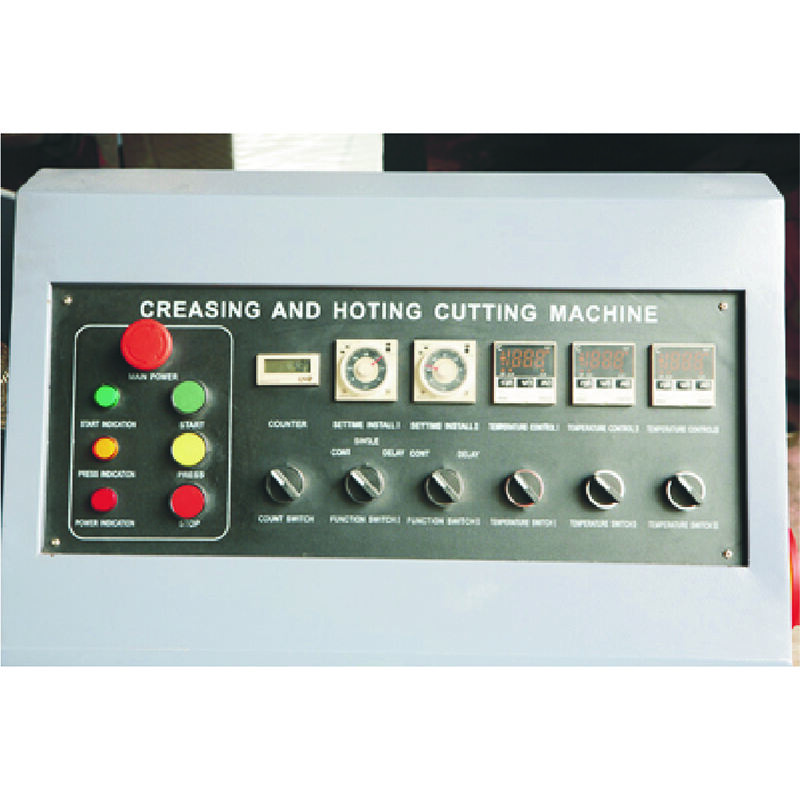

Contemporary creasing machines incorporate sophisticated digital control panels that revolutionize operator interaction and machine management. These interfaces provide real-time monitoring of operational parameters, allowing operators to adjust settings with unprecedented precision. Touch-screen displays present intuitive navigation menus, enabling quick access to job settings, maintenance schedules, and performance analytics. The integration of digital technology eliminates guesswork from setup procedures, ensuring consistent results across production runs.

Advanced control systems also feature programmable memory functions that store frequently used configurations. This capability significantly reduces setup time between jobs, particularly beneficial for facilities handling multiple product types throughout a single shift. The ability to recall precise settings instantly minimizes material waste during changeovers and maintains consistent quality standards regardless of operator experience levels.

Automated Calibration Features

Automated calibration represents a significant advancement in creasing machine technology, eliminating manual adjustment procedures that previously consumed valuable production time. These systems continuously monitor operational parameters and make real-time corrections to maintain optimal performance. Sensors throughout the machine detect variations in material thickness, density, and other critical factors, automatically adjusting pressure and positioning accordingly.

The precision achieved through automated calibration extends far beyond manual capabilities, delivering consistent results that meet stringent quality requirements. This technology proves particularly valuable when processing materials with varying characteristics or when switching between different substrate types during production runs. Automated systems maintain accuracy levels that would be impossible to achieve through manual adjustment alone.

Enhanced Material Handling Capabilities

Multi-Format Compatibility

Modern creasing machines excel in handling diverse material formats, accommodating everything from lightweight papers to heavy cardboards and synthetic substrates. This versatility stems from advanced feeding mechanisms that automatically adjust to different material characteristics without requiring extensive manual reconfiguration. Variable pressure systems ensure optimal creasing results across the entire spectrum of supported materials.

The ability to process multiple formats within a single production run enhances operational flexibility and reduces the need for multiple specialized machines. This capability proves particularly valuable for businesses serving diverse markets or those experiencing seasonal variations in product requirements. Advanced material handling systems maintain consistent quality standards regardless of substrate variations.

High-Speed Processing Systems

Contemporary creasing machines incorporate high-speed processing capabilities that dramatically increase throughput without compromising accuracy. Advanced drive systems maintain consistent speeds across varying load conditions, ensuring uniform crease quality throughout extended production runs. Servo motor technology provides precise speed control and rapid acceleration, minimizing cycle times while maintaining exceptional positioning accuracy.

Speed optimization extends beyond raw processing velocity to encompass overall workflow efficiency. Quick-change tooling systems enable rapid transitions between different crease configurations, while automated material handling reduces manual intervention requirements. These features combine to deliver significant improvements in overall productivity and operational efficiency.

Precision Engineering and Quality Control

Servo-Driven Positioning Systems

Servo-driven positioning systems represent the pinnacle of precision in modern creasing machine design. These systems provide micron-level accuracy in tool positioning, ensuring consistent crease placement across entire production runs. The precise control offered by servo technology eliminates the variations inherent in mechanical systems, delivering uniform results that meet the most demanding quality specifications.

The repeatability achieved through servo-driven systems proves particularly valuable for applications requiring tight tolerances or complex folding patterns. These systems maintain accuracy levels that remain consistent over extended periods, reducing the need for frequent adjustments and minimizing production interruptions. The investment in servo technology typically provides rapid returns through improved quality and reduced waste.

Integrated Quality Monitoring

Integrated quality monitoring systems continuously assess output quality throughout production runs, identifying potential issues before they result in significant waste or downtime. Vision systems inspect crease quality, detecting variations in depth, positioning, or consistency that might indicate developing problems. Real-time feedback enables immediate corrective actions, maintaining quality standards while minimizing material loss.

Advanced monitoring systems also collect comprehensive production data, enabling detailed analysis of operational trends and performance patterns. This information proves invaluable for preventive maintenance scheduling, process optimization, and quality improvement initiatives. The ability to identify and address potential issues proactively significantly reduces unplanned downtime and associated costs.

Operational Efficiency Enhancements

Reduced Setup Times

Modern creasing machines incorporate numerous features designed to minimize setup times and maximize productive operation. Quick-change tooling systems enable rapid transitions between different job requirements, often reducing changeover times from hours to minutes. Preset positioning systems automatically move components to predetermined locations, eliminating time-consuming manual adjustments.

The reduction in setup times directly translates to increased machine utilization and improved profitability. Facilities can accommodate more jobs per shift or respond more quickly to urgent customer requirements. The flexibility provided by rapid setup capabilities enables businesses to pursue shorter-run opportunities that might otherwise be economically unfeasible.

Energy Efficiency Optimization

Contemporary creasing machines incorporate advanced energy management systems that significantly reduce operational costs while supporting environmental sustainability initiatives. Variable-speed drives adjust power consumption based on actual processing requirements, eliminating the waste associated with constant full-power operation. Intelligent standby modes reduce energy consumption during idle periods without affecting response times.

Energy-efficient designs often incorporate regenerative braking systems that capture and reuse energy during deceleration cycles. LED lighting systems provide superior illumination while consuming minimal power, and optimized heating systems maintain consistent temperatures with reduced energy requirements. These features combine to deliver substantial reductions in operational costs over the machine's service life.

Maintenance and Reliability Features

Predictive Maintenance Systems

Advanced creasing machines incorporate sophisticated predictive maintenance systems that monitor component condition and predict potential failures before they occur. Vibration sensors, temperature monitors, and performance analyzers continuously assess critical systems, identifying developing issues that require attention. This proactive approach significantly reduces unplanned downtime while optimizing maintenance costs.

Predictive maintenance systems generate detailed reports that enable maintenance personnel to schedule service activities during planned downtime periods. This approach minimizes disruption to production schedules while ensuring optimal machine performance. The ability to address potential issues before they result in failures dramatically extends component life and reduces overall maintenance costs.

Modular Component Design

Modular component design facilitates rapid maintenance and repair procedures, minimizing downtime when service is required. Standardized interfaces enable quick component replacement without extensive disassembly or realignment procedures. This design philosophy extends to wear components, which can be replaced quickly using standard tools and procedures.

The modular approach also enables incremental capability upgrades as business requirements evolve. New features or enhanced performance capabilities can often be added through component replacement rather than complete machine replacement. This flexibility provides excellent long-term value and protects equipment investments over extended periods.

FAQ

What material thickness ranges can modern creasing machines handle

Modern creasing machines typically accommodate materials ranging from 80gsm papers to 2000gsm cardboards, with some specialized units handling even thicker substrates. Advanced pressure control systems automatically adjust to material characteristics, ensuring optimal results across the entire supported range. The specific capabilities vary by model and manufacturer, making it essential to match equipment specifications to actual application requirements.

How do automated features impact operator skill requirements

Automated features significantly reduce the skill level required for basic operation while enabling experienced operators to achieve higher productivity levels. Digital interfaces guide operators through setup procedures, while automated calibration eliminates the need for manual adjustments. However, understanding the underlying principles remains valuable for troubleshooting and optimization purposes.

What factors determine the return on investment for upgrading equipment

ROI calculations should consider increased productivity, reduced waste, lower labor costs, energy savings, and improved quality consistency. Many facilities experience payback periods of 12-24 months through combination of these benefits. The specific return depends on current equipment age, production volumes, labor rates, and material costs in each facility.

How do maintenance requirements compare between traditional and modern systems

Modern systems generally require less frequent maintenance due to advanced materials and improved engineering, but may require specialized diagnostic equipment and training. Predictive maintenance capabilities often extend component life while reducing emergency repairs. Overall maintenance costs typically decrease while reliability significantly improves compared to older mechanical systems.